rope grip

A technology of rope clamps and clamping blocks, which is applied in the field of rope clamps, can solve the problems of difficult positioning of movable clamping blocks and low action sensitivity of rope clamps, achieve simple and convenient installation and positioning, improve action flexibility, and facilitate impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

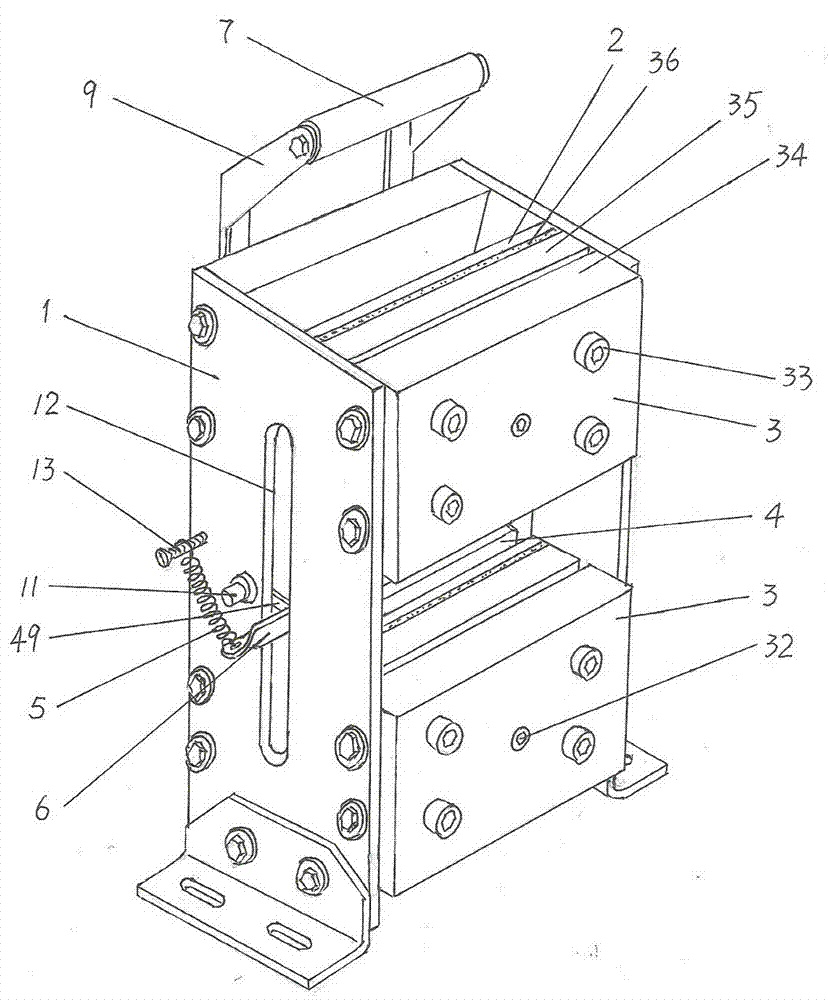

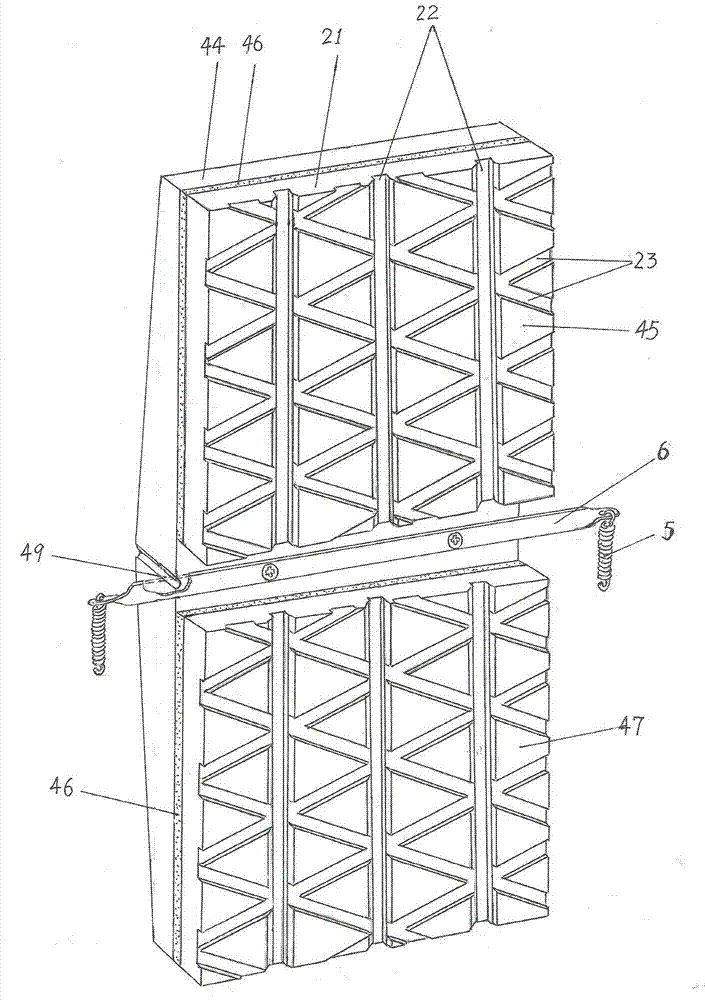

[0025] like figure 1 As shown, the rope clamp of the present invention includes a frame 1, a fixed clamp block 3 fixed in the frame, and a movable clamp block 4 arranged opposite to the fixed clamp block; Friction plates 2 are respectively attached to them; the gap between the movable clamp block 4 and the fixed clamp block 3 is a rope passage for the steel wire rope to pass through.

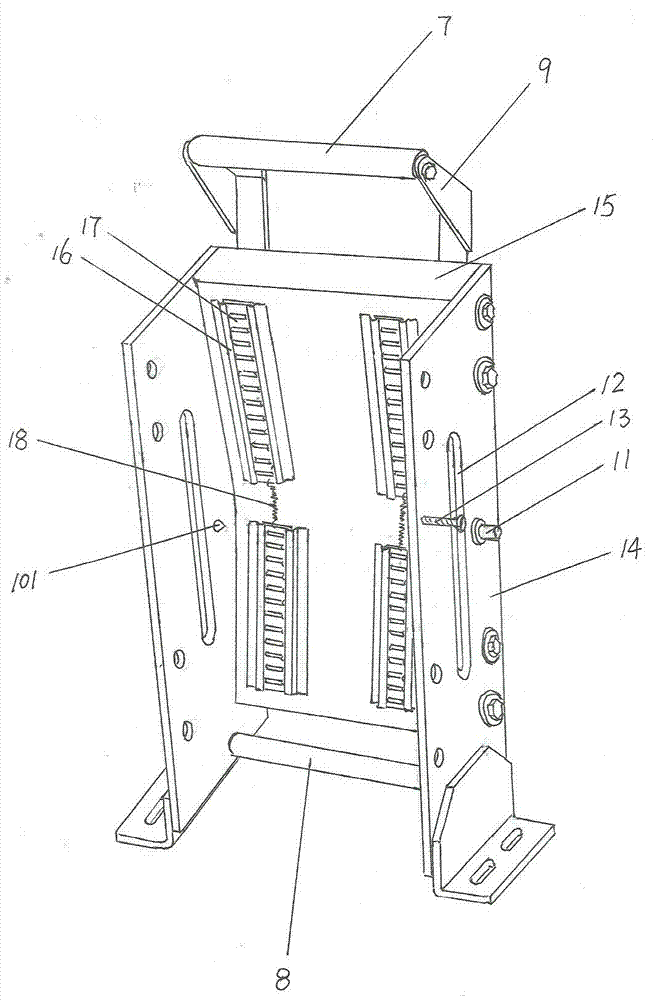

[0026] like figure 2 As shown, the frame 1 is a trough-shaped body surrounded by two side plates 14 and an end plate 15 located between the two side plates. On the two slopes of the inner wall of the end plate 15, two slideways 16 are respectively arranged, and the slideways on the two slopes face each other end to end and keep a certain distance, and a roller shaft row 17 is arranged in each slideway 16. . Shaft roller row 17 is to open a row of parallel tunnels on a plate surface, and a rotatable roller shaft is set in each tunnel to form a row of roller shaft rows with substantially equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com