Automatic trimming machine for air filter element of automobile

An air filter and trimming machine technology, applied in metal processing and other directions, can solve the problems of high labor intensity, low work efficiency, unfavorable factory production automation, etc., and achieve the effect of simple operation, efficient and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

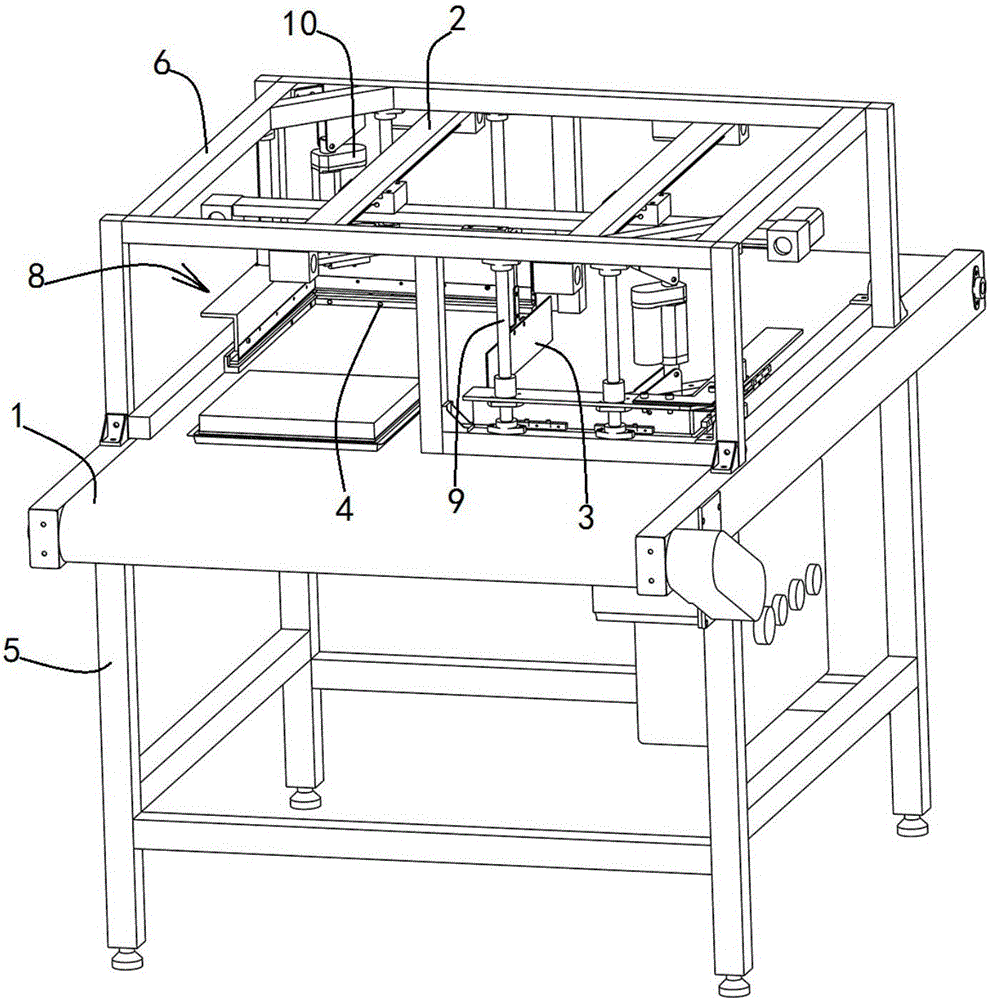

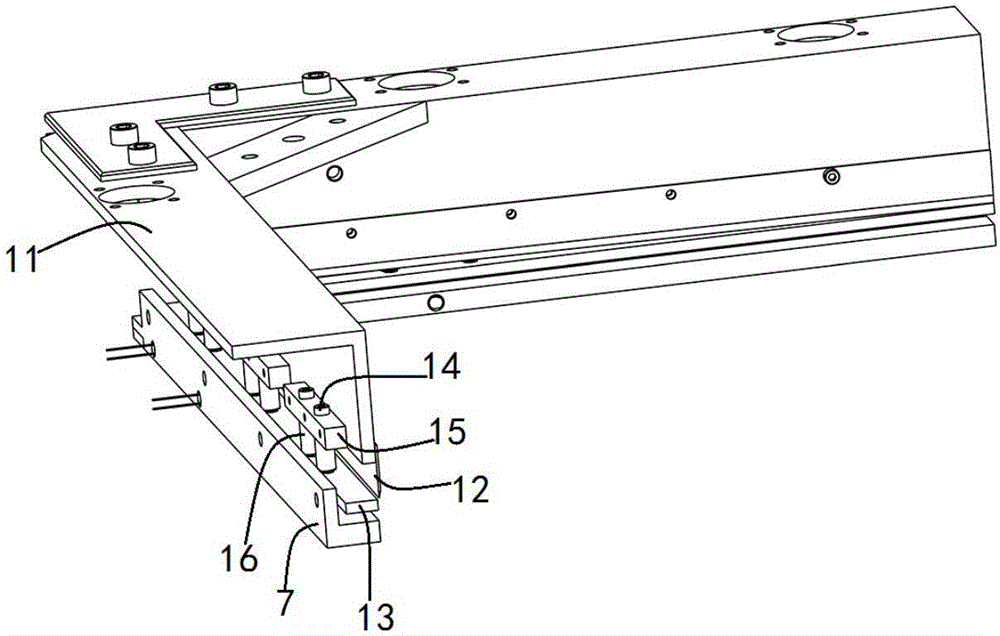

[0015] Such as figure 1 , figure 2 As shown, the auto air cleaner filter core automatic trimming machine proposed by the present invention includes a station transfer assembly and a cutting assembly, the station transfer assembly transfers the filter element between the loading and unloading stations, and the cutting assembly removes the burr of the filter element outer frame , the station transfer assembly includes a conveyor belt 1, a plane two-degree-of-freedom slide table 2, a paddle 3 and a photoelectric positioning sensor 4, the conveyor belt is installed on a frame 5, and the frame has a mounting frame 6, a plane two-degree-of-freedom slide table and The pick is installed on the installation frame, and the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com