Multi-joint robot

A multi-joint robot and swing mechanism technology, applied in the field of robotics, can solve the problems of high price of steering gear, failure of steering gear performance to meet the use requirements, increase of production cost of mannequin robots, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can conceive of other obvious modifications. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

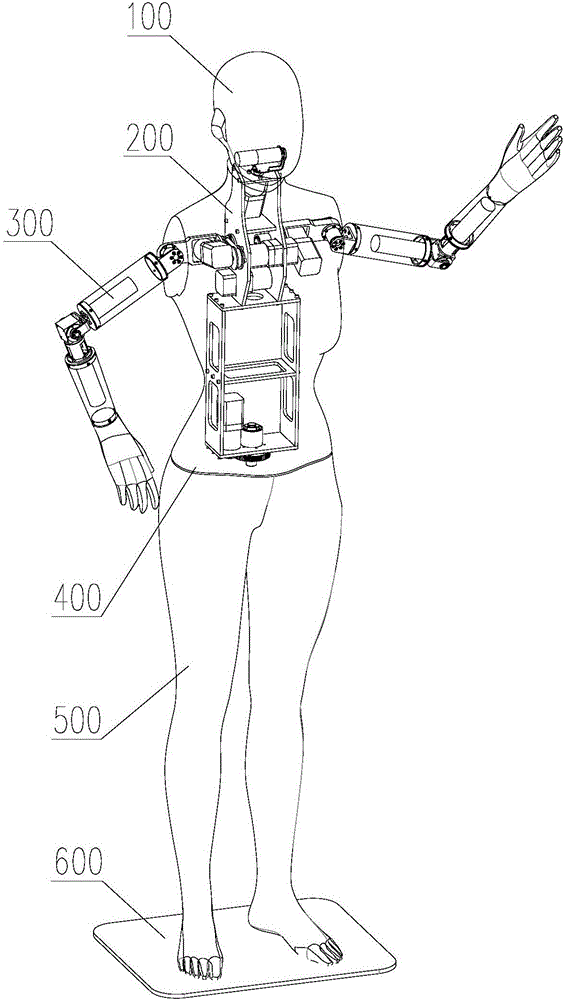

[0033] The multi-joint robot of the present invention mainly includes an upper body shell 400 and an arm shell 300, and the head shell 100 and the lower body shell 500 connected with the upper body shell 400 can be selectively installed according to actual conditions.

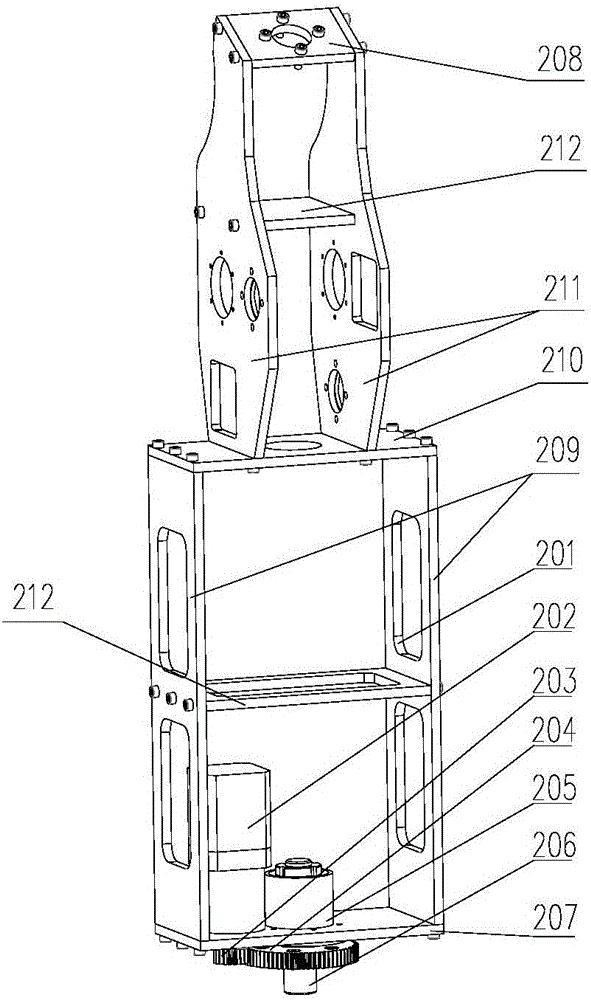

[0034] see figure 1 and Figure 4, shows a multi-joint robot according to a preferred embodiment of the present invention, including an upper body shell 400 and two arm shells 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com