Additional shaft clamping mechanism of gantry machining machine

A clamping mechanism and additional shaft technology, applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable clamping force and large volume, and achieve the effect of stable clamping and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable your review committee to have a further understanding and recognition of the features and characteristics of the present invention, the following preferred embodiments are listed below and described as follows with the help of drawings:

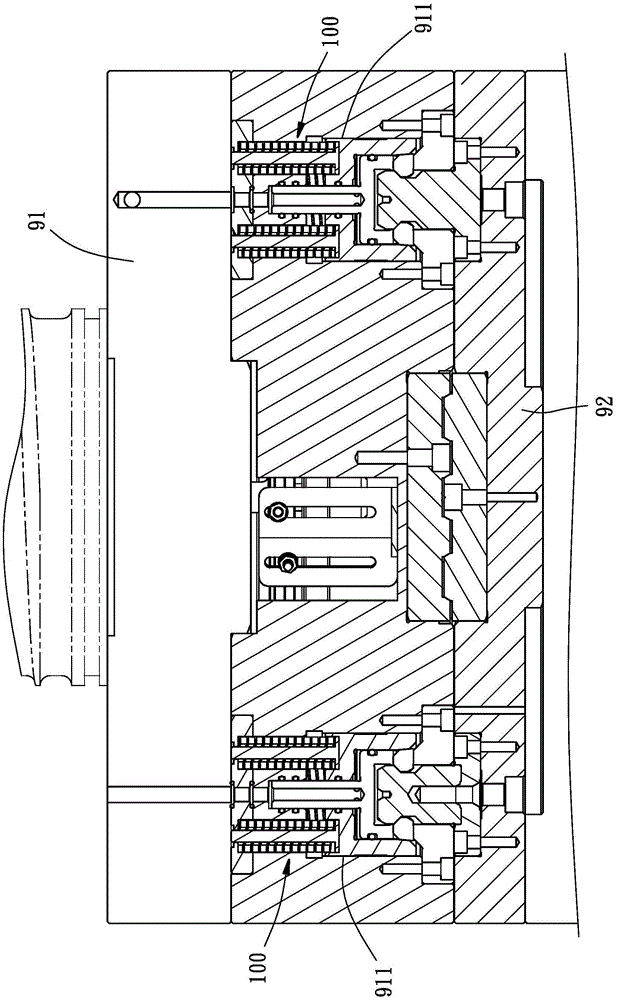

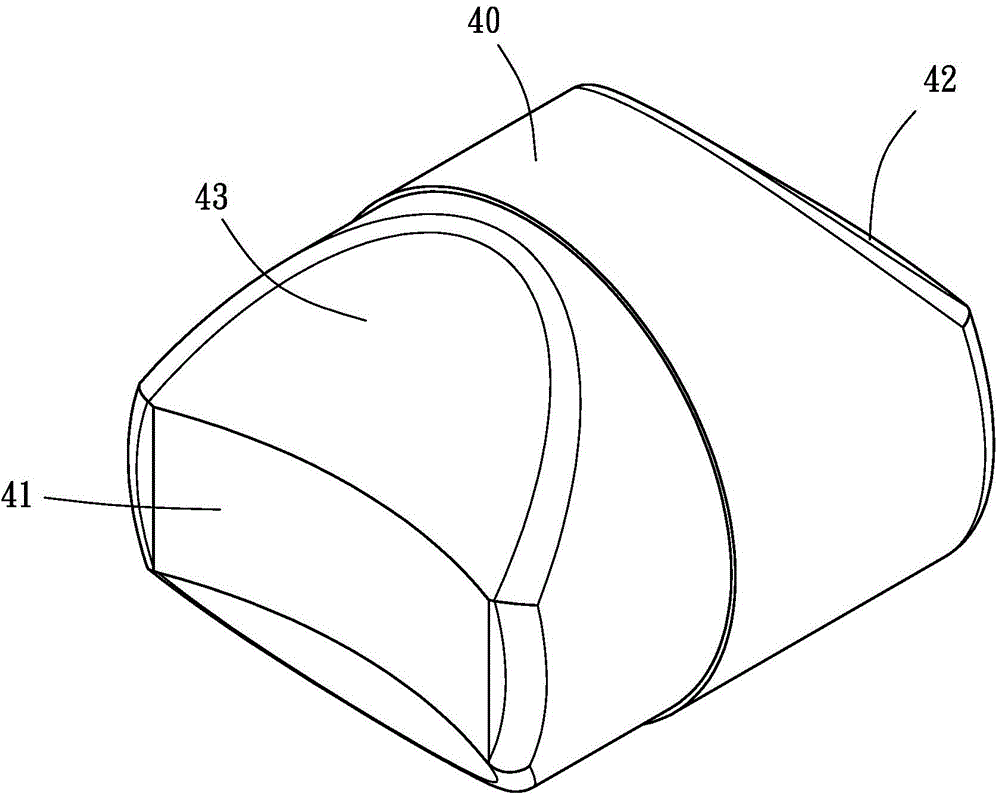

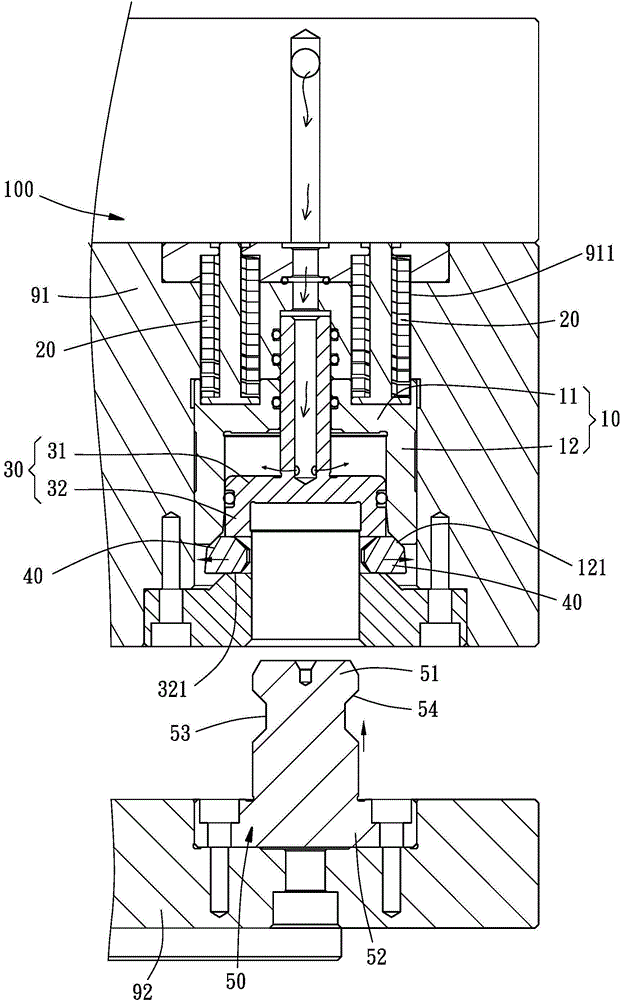

[0032] see Figure 1 to Figure 5 , is an additional shaft clamping mechanism 100 of a gantry processing machine provided by a preferred embodiment of the present invention, used to combine and separate a main shaft 91 and an additional shaft 92, which mainly includes an outer cover body 10, several The spring 20, an inner cover body 30, some clip blocks 40 and a positioning column 50, wherein:

[0033] see Figure 1 to Figure 5 , the outer cover body 10 is movably arranged in a chamber 911 opened by the main shaft 91, and can be reciprocated from an upper top position to a lower push position by an external force. The outer cover body 10 has an outer cover top The wall 11 and an outer cover peripheral wall 12 integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com