A kind of polymer hollow fiber membrane with large flux symmetrical structure and preparation method thereof

A technology with symmetrical structure and large flux, applied in the field of membrane separation, can solve the problems of low porosity of polymer membrane, easily damaged separation layer, low separation accuracy, etc., achieve low elution rate, and facilitate large-scale development and production , the effect of high separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

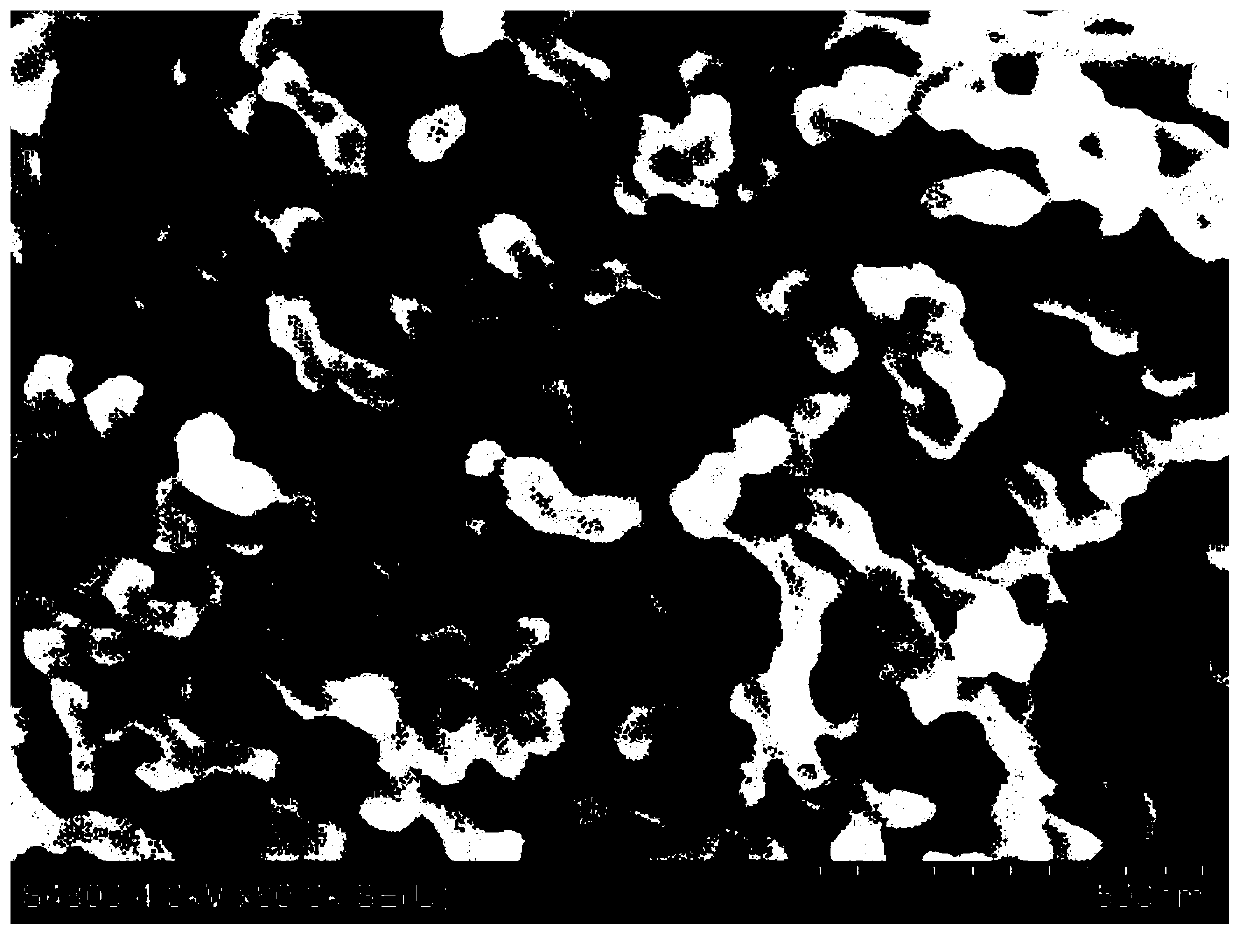

[0034] Add 35 grams of polysulfone and 65 grams of N,N'-dimethylacetamide into the reaction kettle, blow nitrogen, and keep stirring at 130°C until fully dissolved; add 1.75 grams of acrylic acid (5% of the mass of polysulfone), vinyl 1.75 grams of triethoxysilane (100% of the quality of acrylic acid), 0.175 grams of azobisisobutyronitrile (10% of the quality of acrylic acid), 3.5 grams of water (20% of the quality of acrylic acid), reacted at 60°C for 36 After vacuum defoaming, the film-making liquid was obtained; it was co-extruded with the core liquid (water) through the spinneret through a metering pump, stayed in the air for 0.5 seconds, and then immersed in a water bath with a pH of 2 at 10°C to solidify and form a film , winding, and cleaning to obtain a polysulfone hollow fiber membrane with a large flux and symmetrical structure;

[0035] The water contact angle of the polysulfone hollow fiber membrane with large flux symmetrical structure prepared in Example 1 is 67°...

Embodiment 2

[0037] Add 15 grams of polyethersulfone and 85 grams of N,N'-dimethylformamide into the reaction kettle, blow nitrogen, and keep stirring at 20°C until fully dissolved; add 9 grams of methacrylic acid (60% of the mass of polysulfone) , 0.09 gram of vinyltrimethoxysilane (1% of acrylic acid quality), 0.18 gram of azobisisoheptanonitrile (2% of acrylic acid quality), 0.045 gram of dehydrated alcohol (0.5% of acrylic acid quality), 130 Reaction at ℃ for 4 hours, vacuum defoaming to obtain film-making liquid; co-extrude it and core liquid (mixed solution of water and N-methylpyrrolidone, wherein the mass content of water is 60%) through the spinneret through a metering pump , stay in the air for 5 seconds, then immerse in a water bath at 100°C and pH 10 to solidify to form a membrane, wind up, wash, and obtain a polyethersulfone hollow fiber membrane with a large flux symmetrical structure;

[0038] The water contact angle of the large-flux symmetrical polyethersulfone hollow fibe...

Embodiment 3

[0040]Add 20 grams of polysulfone and 80 grams of N-methylpyrrolidone into the reaction kettle, blow nitrogen, and continue to stir at 80°C until fully dissolved; add 4 grams of dimethylaminoethyl methacrylate (20% of the mass of polysulfone), 2 grams of methacryloyloxypropyl tris (trimethylsiloxane) silane (50% of the quality of dimethylaminoethyl methacrylate), 0.004 grams of dibenzoyl peroxide (dimethacrylate 0.1% of the quality of methylaminoethyl ester), 0.4 grams of hydrochloric acid (10% of the quality of dimethylaminoethyl methacrylate), reacted for 12 hours at 80°C, and obtained the film-making liquid after vacuum defoaming; (a mixed solution of water and N,N'-dimethylacetamide, wherein the mass content of water is 30%) is co-extruded through the spinneret through a metering pump, staying in the air for 60 seconds, and then immersed in 90 ° C, pH 8. Solidify into a film in a water bath, wind up, and wash to obtain a polysulfone hollow fiber membrane with a large flux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com