Conveying chain

A technology for conveying chains and chain links, applied in the field of chains, can solve problems such as inconvenience and waste, and achieve the effect of prolonging service life, ensuring normal use, and prolonging the use time of a single refueling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

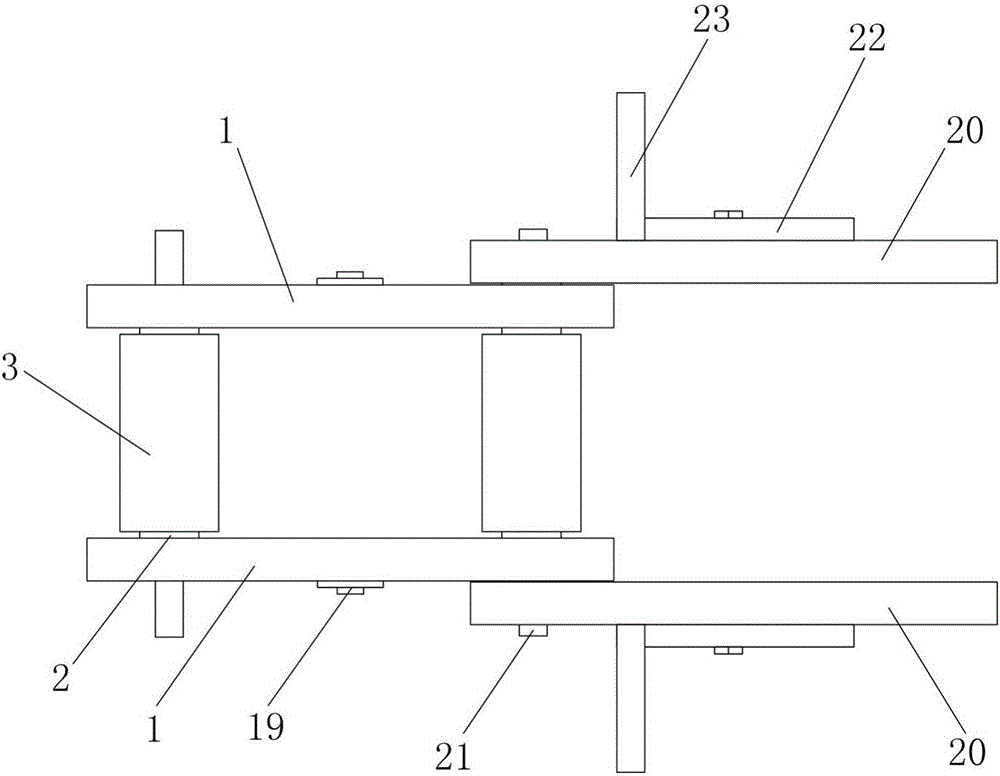

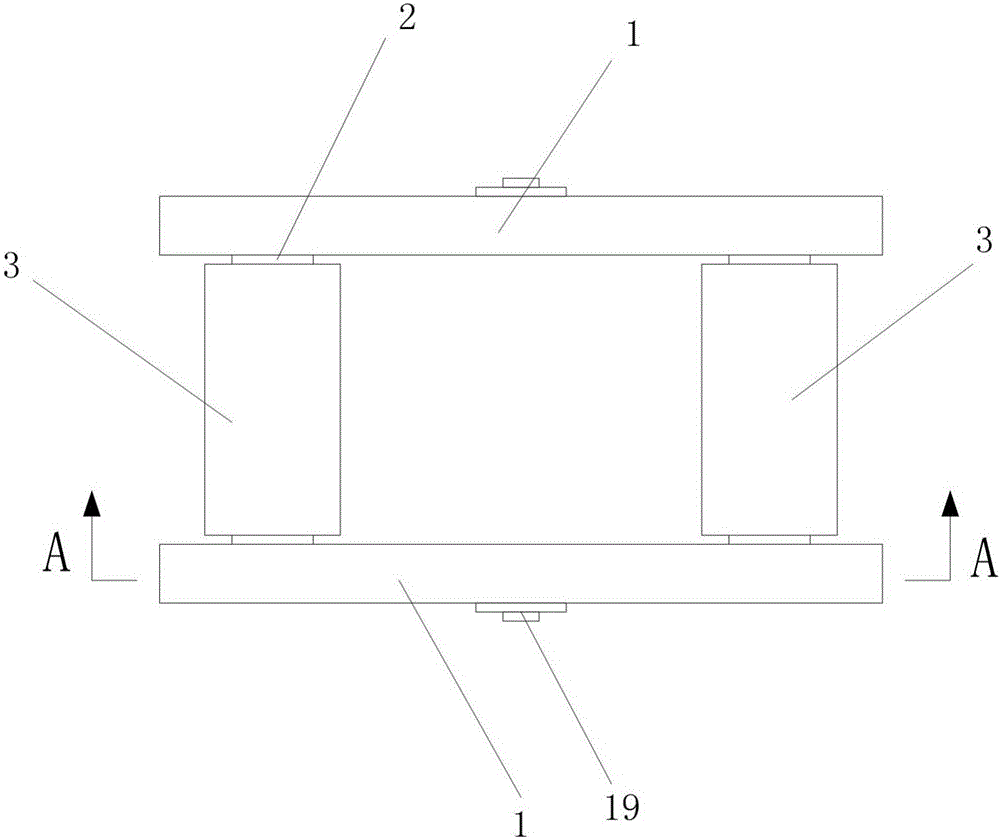

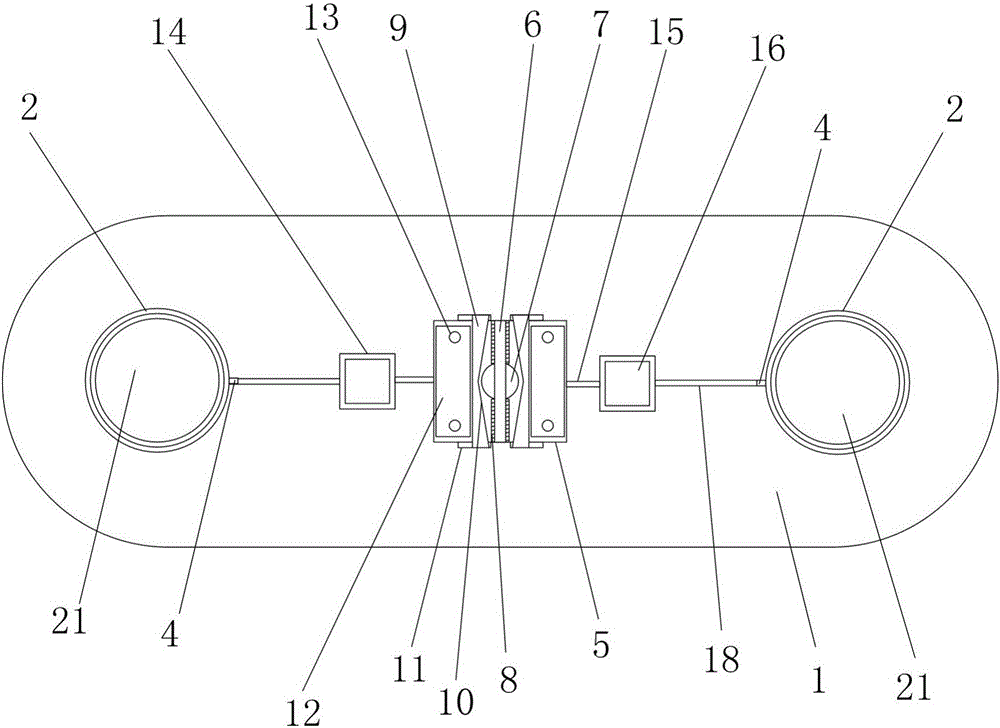

[0043] Such as Figure 1-5 As shown, the conveyor chain provided by the present invention is composed of chain links in sequence; each chain link includes two inner chain plates 1, two outer chain plates 20, two rollers 3, two sleeves 2 and two Pin shaft 21;

[0044] The two inner chain plates 1 are arranged in parallel and facing each other;

[0045] The two sleeves 2 are arranged in parallel between the two inner chain plates 1, and a circle of limiting bead is provided on the outer circumference of the sleeve 2;

[0046] The two rollers 3 are sleeved on the two sleeves 2 respectively, and a limit groove is provided on the inner circumference of the rollers 3;

[0047] The said limiting protruding ring is embedded in the limiting groove, and can be rotated relatively, and the position of the roller 3 is relatively fixed by using the cooperation of the limiting protruding ring and the limiting groove, and will not interfere with the inner chain plate 1. The inside causes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com