Full-automatic lifting type transferring machine

A transfer machine, fully automatic technology, applied in the field of conveying, can solve the problem that the automatic lifting transfer machine cannot be applied, and achieves the effect of good improvement difficulty, good rigidity and increased structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

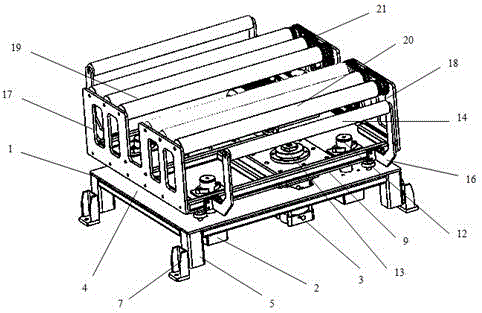

[0029] like figure 1 As shown, a fully automatic lifting and transferring machine includes a bottom lifting mechanism, a lifting support frame installed above the bottom lifting mechanism, and a conveying roller mechanism installed on the lifting support frame. The overall structure is made of high-quality carbon steel and the surface is painted, with high strength, good rigidity, light weight and wear resistance, which ensures the stability of operation.

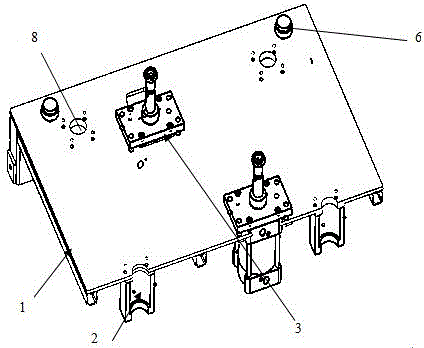

[0030] like figure 2 As shown, the bottom lifting mechanism includes a frame 1, a linear bearing 2 fixed below the frame 1, and a jacking cylinder 3 that provides power for the lifting mechanism of the transfer machine. The frame 1 includes a support plate 4 and a support leg 5 installed below the support plate 4. A b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com