Three-color liquid silicone injection molding device

A liquid silicone and injection molding technology, which is applied in the field of three-color liquid silicone injection molding devices, can solve the problems of rising production costs, declining product quality, and restricting product design and production, and achieves the effect of convenient mutual position relationship and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

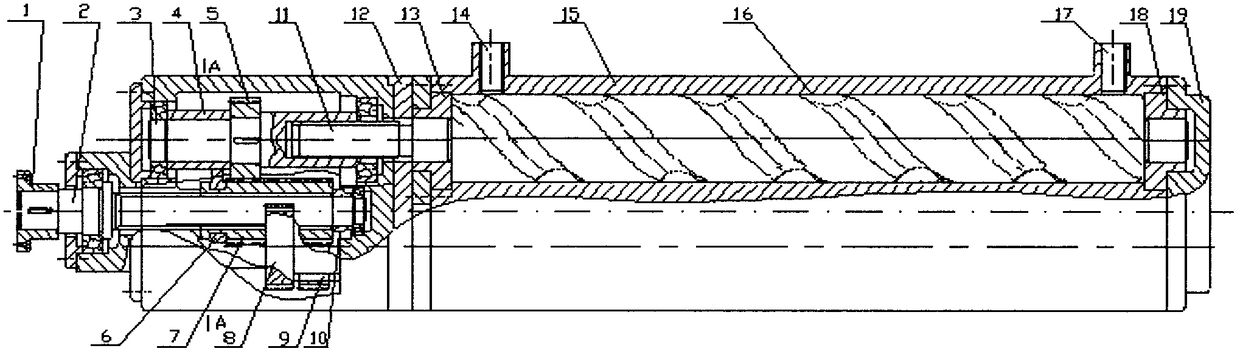

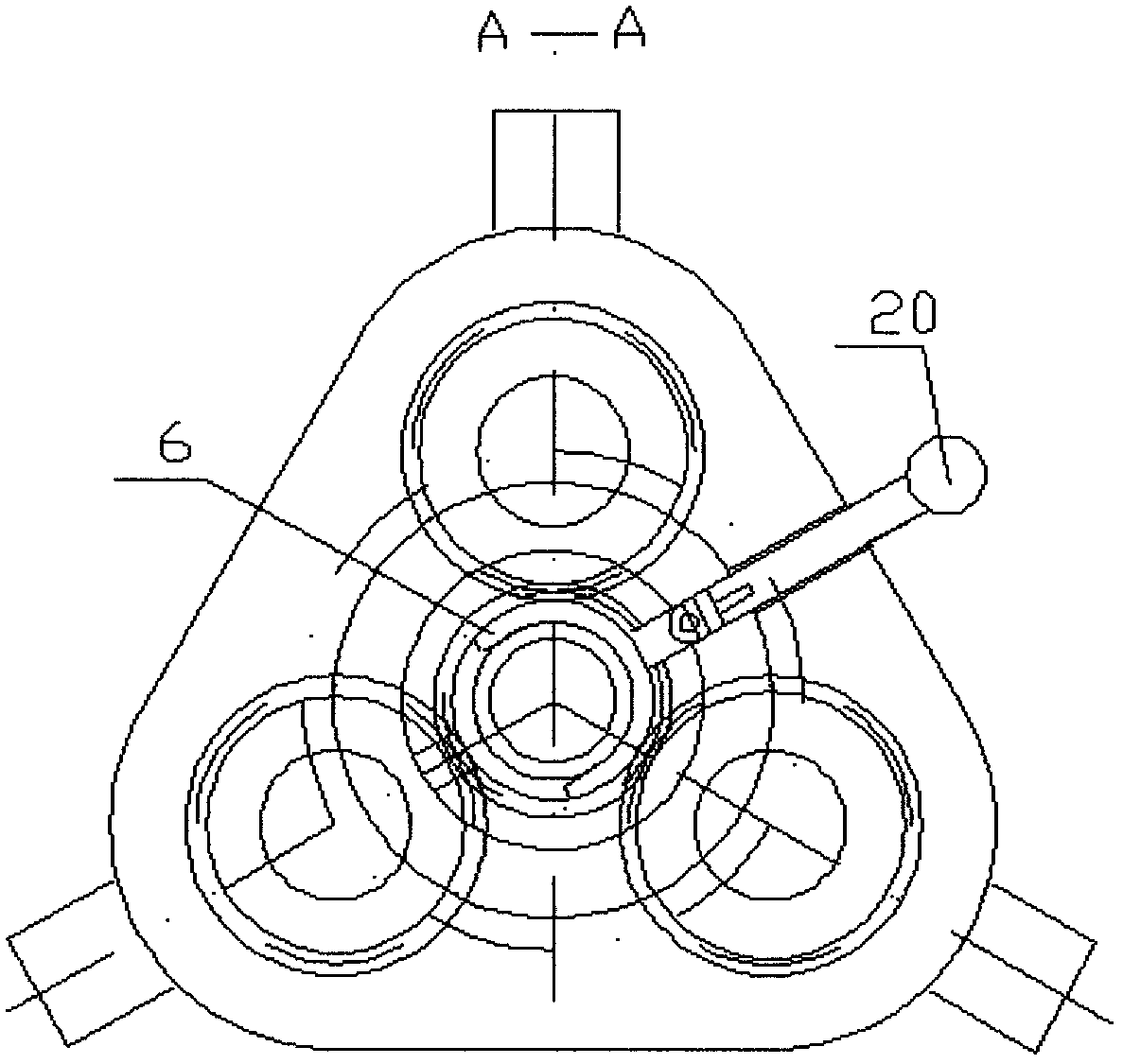

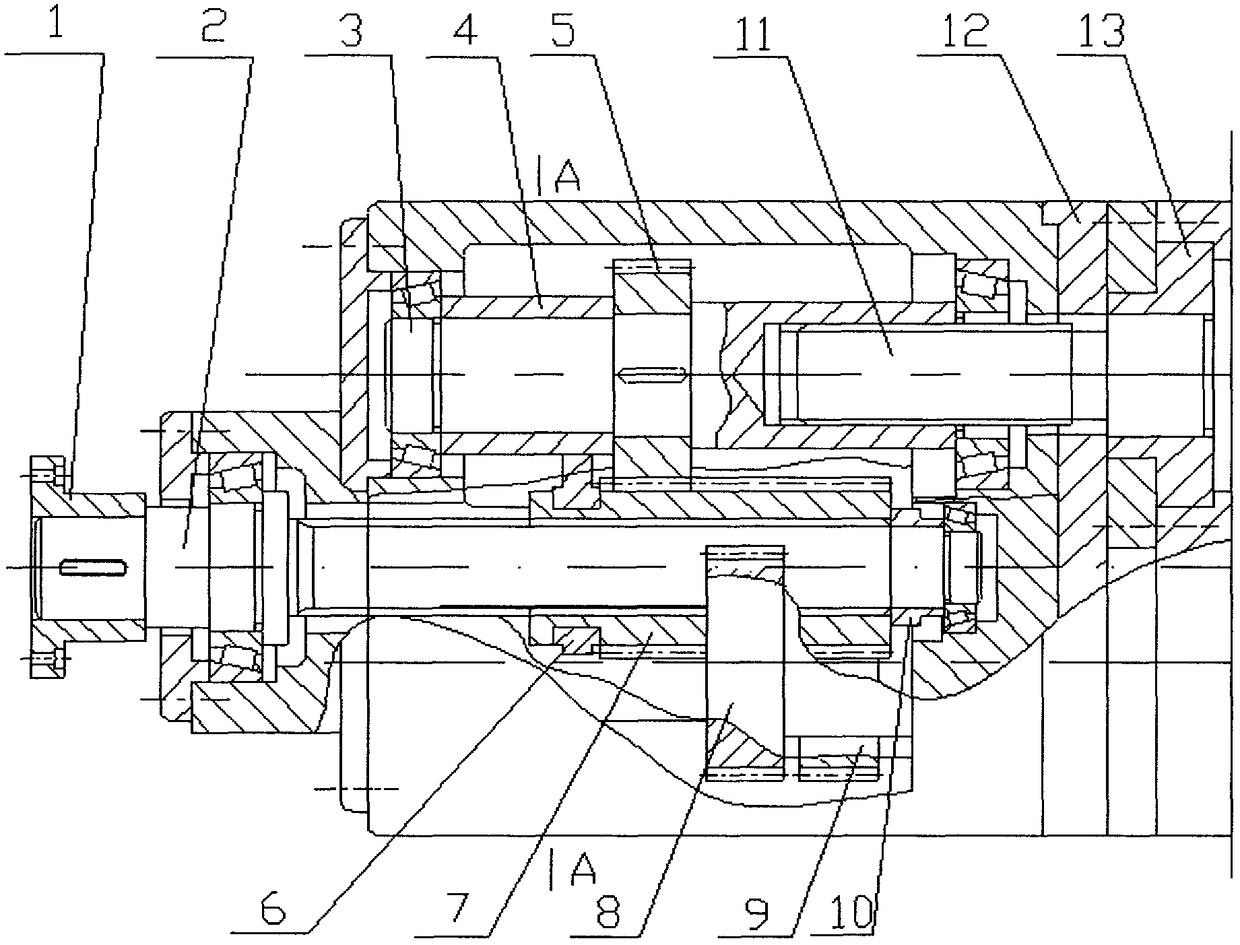

[0015] The accompanying drawing is a three-color liquid silicone injection molding device of the embodiment of the present invention. The invention adopts a multi-cavity transfer method, uses a gear changing box to realize single drive of the screw in the three cavities, two-axis drive or three-axis simultaneous drive, and realizes three-cavity simultaneous injection molding or single-cavity and double-cavity injection molding. To achieve the purpose of multi-color liquid silicone injection molding. In the present invention, an intermediate sliding gear 6 drives the transmission gears of three screw pump screws, and the three pump shafts are independent, and each pump shaft is driven by a transmission shaft and a transmission gear. The device of the present invention consists of: coupling 1, intermediate transmission spline shaft 2, one-cavity transmission shaft 3, one-chamber transmission gear limit sleeve 4, one-cavity transmission gear 5, slip gear fork 6, middle slip gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com