Heating joint fixing mechanism of vehicle acoustic part mold

A technology for heating acoustic parts and molds, which is applied in the production field of automobile interior parts, can solve the problems of mold crushing operation and inconvenience, and achieve the effects of avoiding mold crushing, compact structure, and convenient operation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

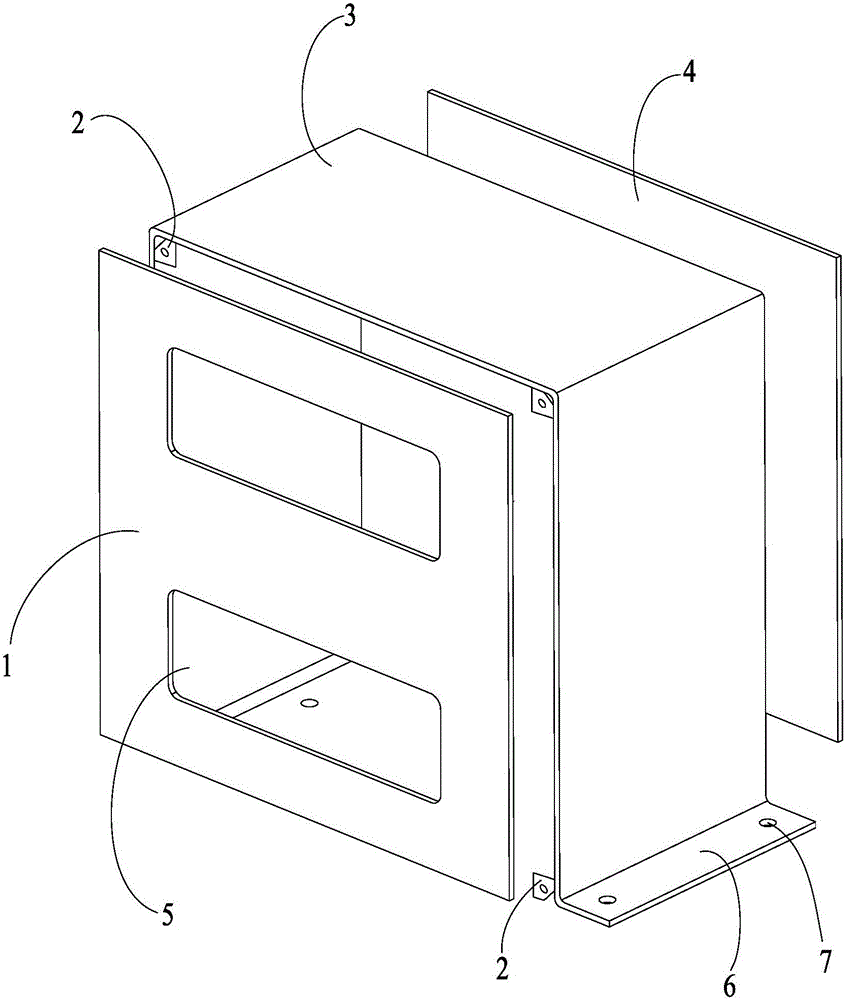

[0013] Such as figure 1 Shown: In order to effectively avoid the risk of the heating joint being crushed by the mold and improve the convenience of use and operation, the present invention includes a shield body for forming a space for accommodating the electric heating pipe harness. The shield body includes a The side guard plate 3, the front guard plate 1 is set on one side of the side guard plate 3, the back guard plate 4 is set on the other side of the side guard plate 3, and the front guard plate 1 is provided for installation The working core group groove 5 of the working core group.

[0014] Specifically, the side guard 3 is U-shaped, and the side guard 3 is provided with a front guard fixing block 2 for connecting with the front guard 1, and the front guard 1 is connected to the front guard of the side guard 3 by bolts. The fixed block 2 is fastened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com