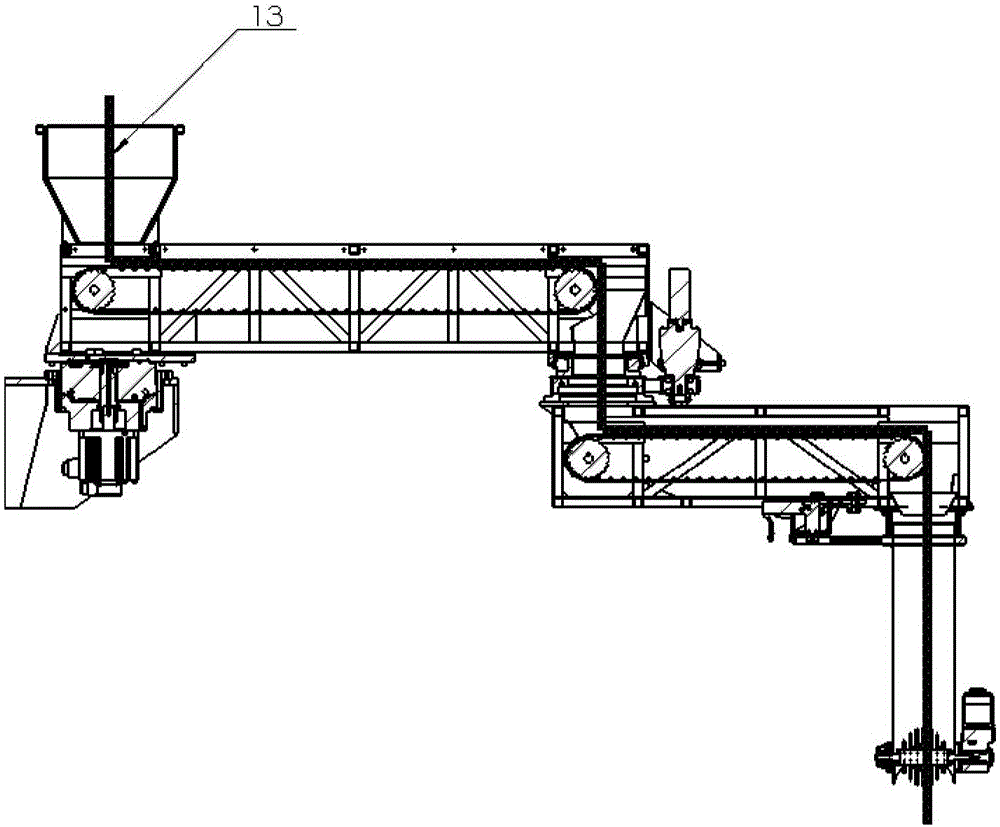

Automatic steamer feeding device

An automatic and blanking technology, applied in the directions of loading/unloading, transportation and packaging, manipulators, etc., can solve the problems of inability to meet the process requirements of the retort, continuous spreading and high cost, reduce labor intensity, improve the efficiency of retort, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical problems solved by the embodiments of the present invention, the technical solutions adopted and the technical effects achieved are clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present application, not all of them. Based on the embodiments in the present application, all other equivalent or obviously modified embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention. Embodiments of the invention can be embodied in many different ways as defined and covered by the claims.

[0028] The basic idea of the embodiment of the present invention is: use the ball screw 14 lifting mechanism to control the swing of the large and small arms through servo drive, RV reducer, and pulley transmission, so that the discharge port is positioned wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com