Hook face longitudinal installation method

An installation method and curved surface technology, applied to the edge of the workpiece, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in ensuring assembly accuracy and welding quality, hidden dangers of closing, and difficulty in assembly, so as to ensure assembly accuracy and welding quality, The effect of reducing welder quality and avoiding difficult processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

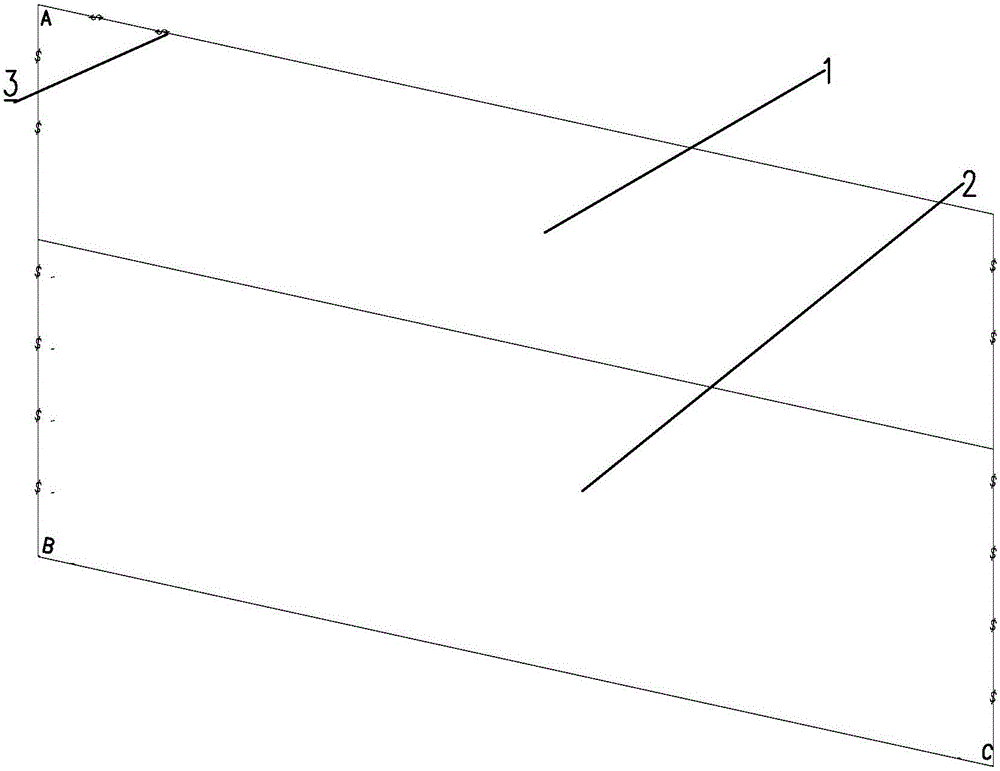

[0033] 1: Such as figure 1 with figure 2 As shown, the bulk outer panels are laid out using any free space, but the structure is facing upwards, which is convenient for marking and welding of longitudinal bones.

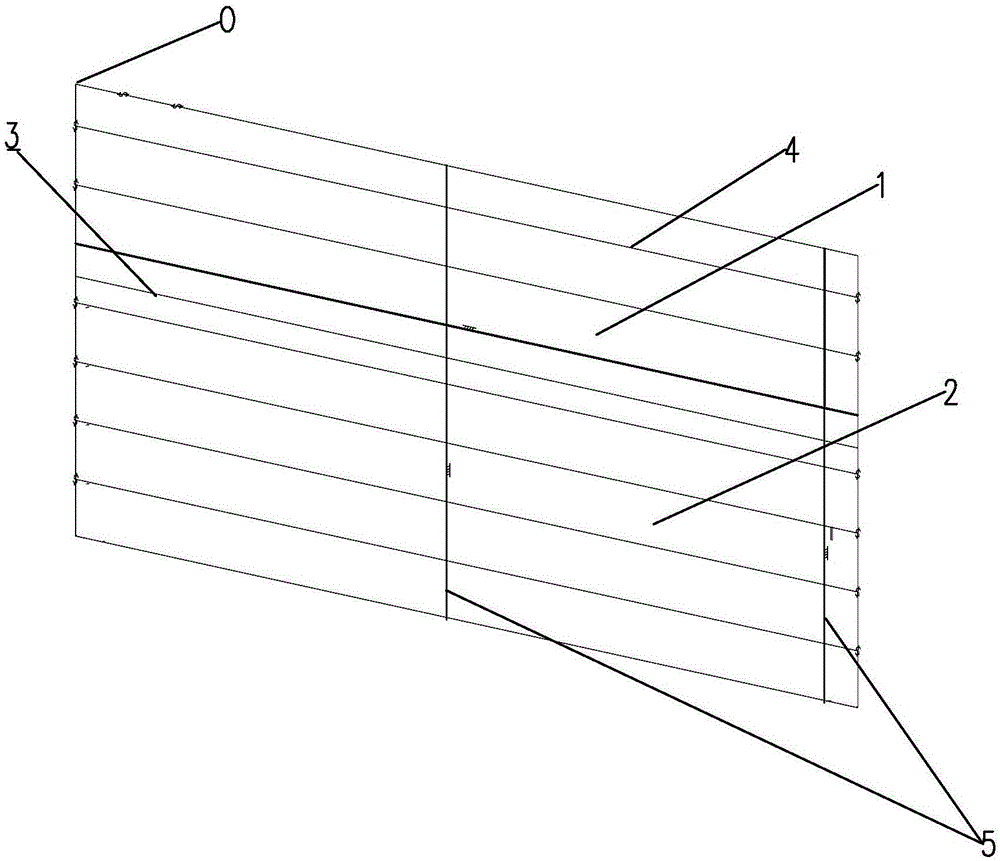

[0034] 2: Such as Figure 5 As shown, the suture line 3 of the first strake on the top of the figure is the scribe line 0:8 and the longitudinal line (including the platform line, the longitudinal bone line, and the suture of the lower orifice of the single strake) is drawn, and the scribe value is the rib position Data expansion value, the rib position draws longitudinal points from the top to the bottom. The relevant points fall on the rib position line 7. The lower plate mouth value 13 of the plate is recorded for future analysis. Connecting the longitudinal points of each rib position line 7 together requires a longitudinal correlation line. Note that the uppermost plate seam edge is if there is any The plate mouth value 13 left by the previous plate is added sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com