Laser impact riveting mold, riveting system and laser impact riveting method for sheet metal

A laser shock, sheet metal technology, applied in laser welding equipment, forming tools, manufacturing tools, etc., can solve the problems of small lateral impact force, small embedded amount, low connection strength, etc., to increase the degree of path change, increase the clip Corner, effect of shortening path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

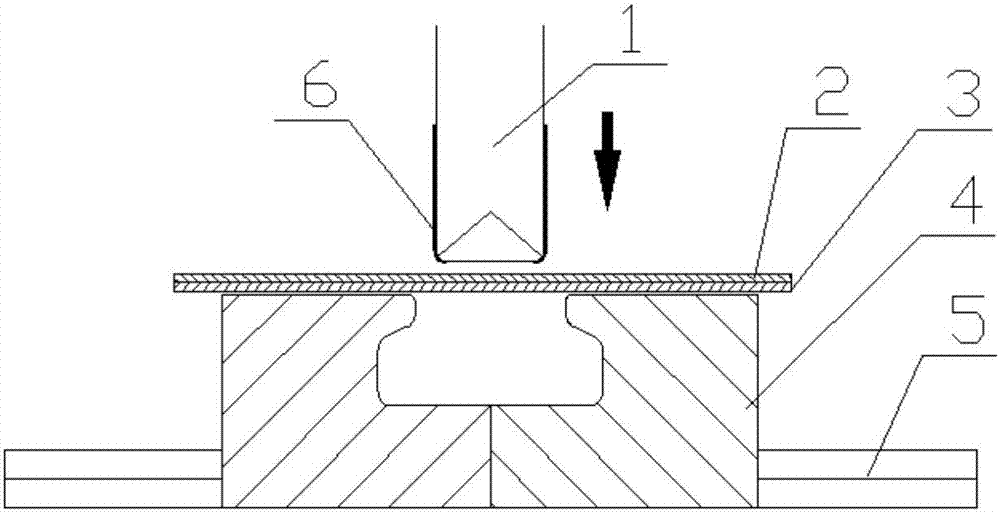

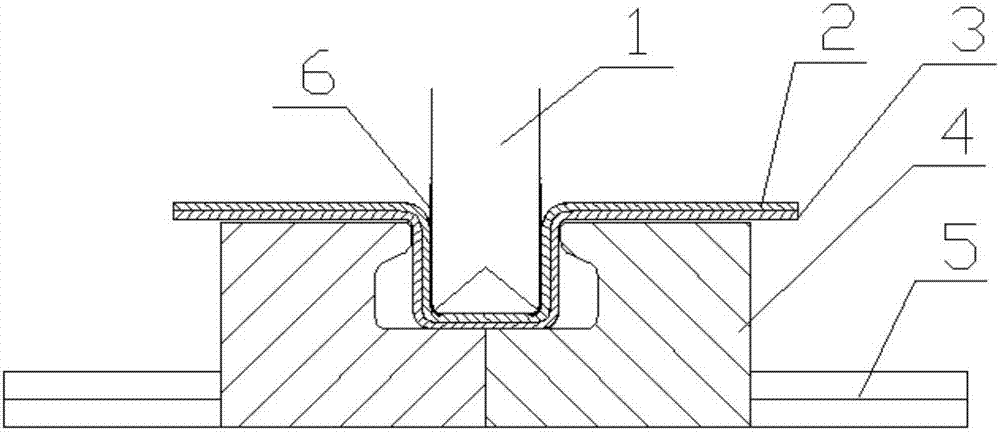

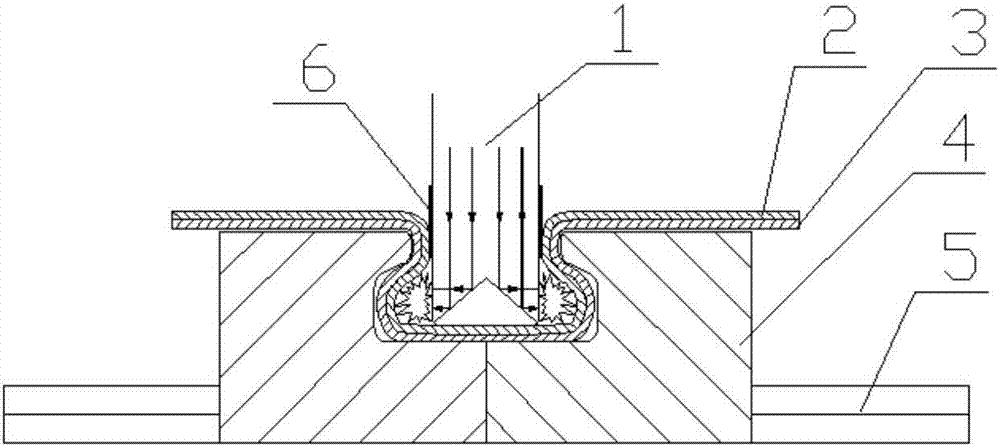

[0080] Such as Figure 1 to Figure 4 As shown, a laser impact riveting die for a plate comprises an upper die 1 and a lower die 4, the upper die 1 is a convex die, the lower surface of the upper die 1 forms a lower pressing surface for the plate, and the material of the upper die 1 is Transparent; the lower end side of the upper mold 1 is covered with an energy absorbing layer 6, and the material in the energy absorbing layer 6 is ionized to form plasma when the laser is irradiated; the lower mold 4 is a concave mold, and grooves are arranged on the concave mold. The inner width of the groove is larger than the width of the opening at the upper end, and the groove is assembled by two parts arranged oppositely;

[0081] The width of the pressing surface of the upper die 1 is smaller than the width of the upper opening of the groove.

[0082] The upper mold 4 has a quadrangular prism structure, and a laser beam path changing structure is arranged inside the upper mold 4 , which...

Embodiment 2

[0085] The difference from Embodiment 1 is that the laser beam path changing structure is a refractive index changing section, and the refractive index of the material in the refractive index changing section changes abruptly, along the direction of laser transmission, the direction of the laser beam is changed by changing the refractive index of the material . The material of the laser propagation path upstream of the interface is the same material, which is referred to as the first material here for convenience of description; the material of the laser propagation path downstream of the interface is the same material, and similarly, for the convenience of description, it is referred to as the first material here. for the second material. The interface between the first material and the second material, that is, the refraction surface is a quadrangular pyramid, the four sides of the bottom surface of the quadrangular pyramid coincide with the four sides of the upper mold resp...

Embodiment 3

[0087] The difference from Embodiment 1 is that the upper mold 1 is a cylindrical structure, and the refractive surface of the refractive index changing section encloses a conical structure, and the apex of the cone is set toward the first material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com