Movable glass lining solid and liquid reactor with vibrating and adjusting functions

A liquid reaction and glass-lined technology, applied in the field of movable glass-lined solid and liquid reaction containers, can solve the problems of shortening the service life of glass-lined reaction tanks, narrowing the scope of application of glass-lined reaction tanks, changing the efficiency and speed of stirring, etc. It achieves the effects of simple structure, improved stirring efficiency, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

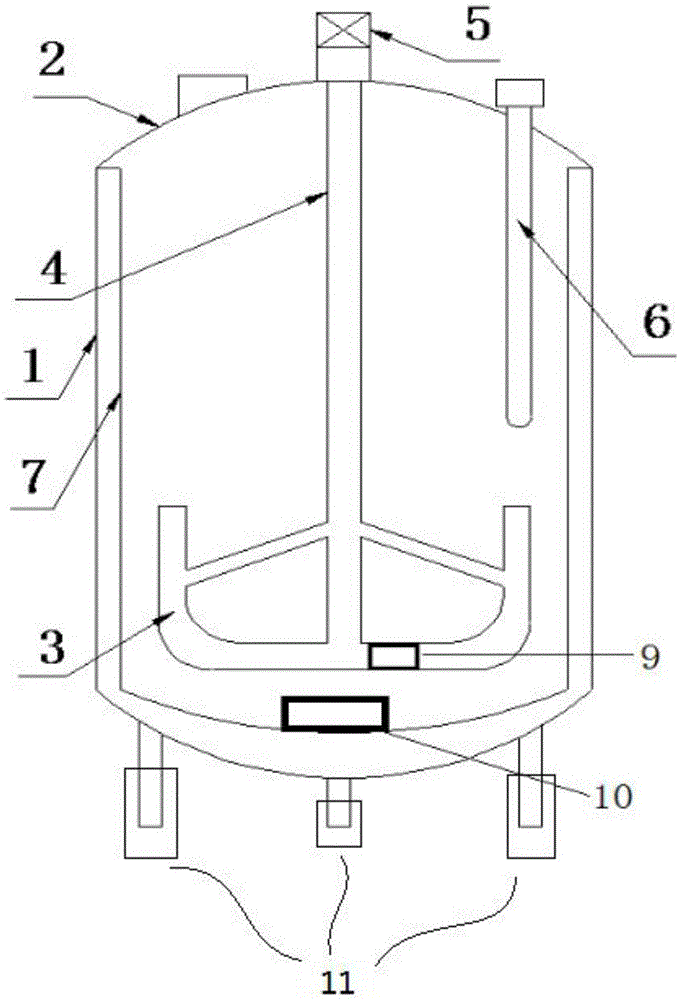

[0012] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

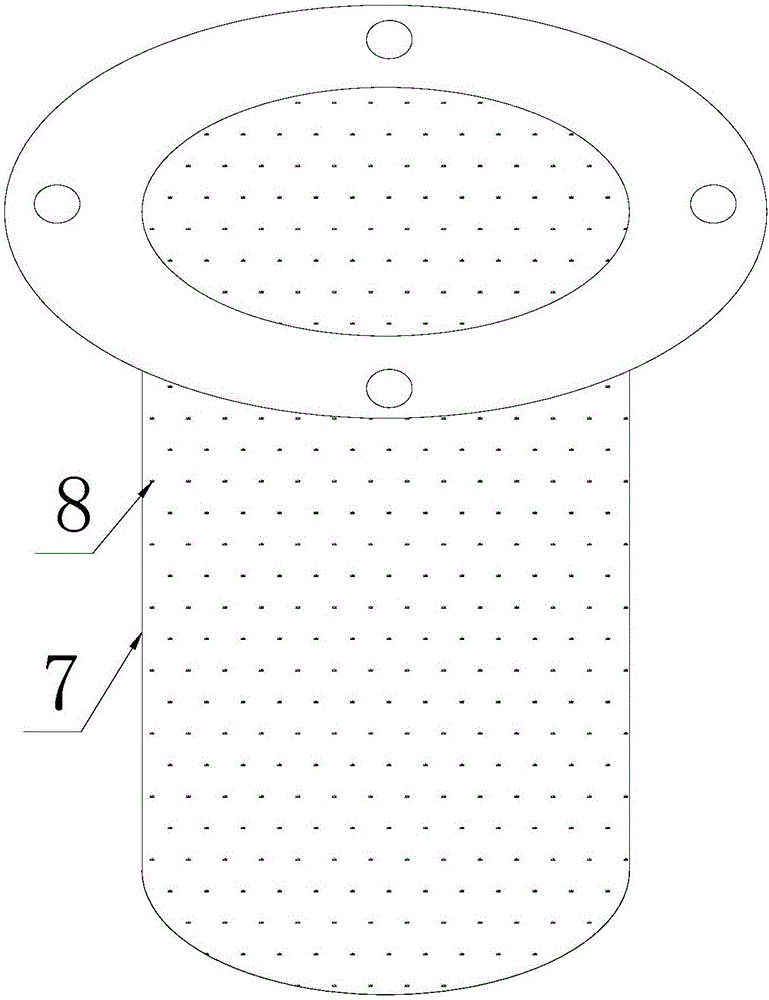

[0013] Such as Figure 1-2 As shown, a movable glass-lined solid and liquid reaction container with vibration and adjustment functions includes a tank body 1, a tank cover 2, a stirrer 4 with stirring blades 3, and a motor 5 connected to the stirrer 4 , thermometer 6, electric control box, electromagnetic vibrator 10, action wheel 11, electromagnetic vibrator 10 is installed on the inner bottom of tank body 1, electromagnetic vibrator 10 is electrically connected with electric control box, speed sensor 9, electric control box and motor 5 Electrically connected, the speed sensor 9 is installed on the stirring paddle 3 at the bottom of the agitator 4, the tank body 1 is equipped with a barrel body 7 with an open upper end, and the upper end of the barrel body 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com