Full-automatic chilli stem cutting machine with automatic basket sieve device

A fully automatic and automatic technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easily damaged bearings, rotating shafts, manpower consumption, material resources, etc., to protect equipment, improve production efficiency, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

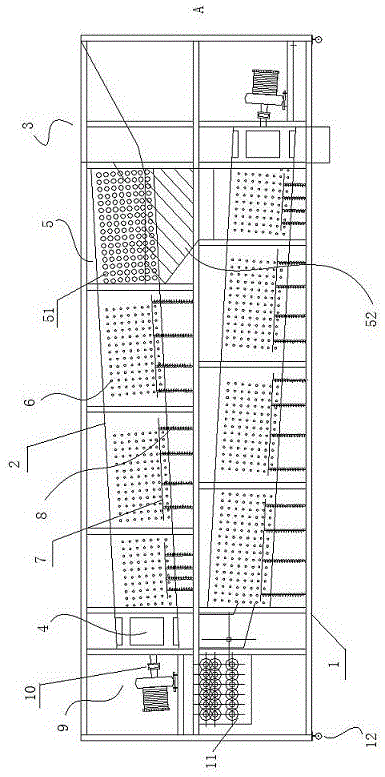

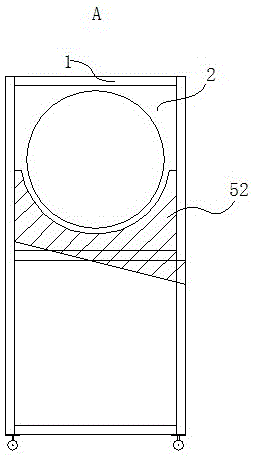

[0016] see Figure 1~2 As shown, the figure shows the structure of a full-automatic pepper cutting machine with an automatic sieve device according to the embodiment of the present invention. For ease of description, only the relevant parts of the embodiment of the present invention are shown.

[0017] A full-automatic chili cutting machine with an automatic sieve device, such as figure 1 , figure 2 As shown, a frame 1 is included, and the frame 1 is arranged as a rectangular frame body, which is convenient for the drum 2 to be arranged in it, and the drum 2 is arranged horizontally in the frame, and one end of the drum 2 is a feed port 3, The other end is the discharge port 4, and the drum 2 is inclined downward from the feed port 3 to the discharge port 4, so that crops suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com