Deep sea pipeline stress corrosion complex loading test device

A stress corrosion and complex loading technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable torsion to test the strength of materials, etc., can solve the problems of complex loading mechanism, single structure and function, and lack of pertinence. Achieve the effect of simple loading mechanism, simple principle and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the present invention will be further described:

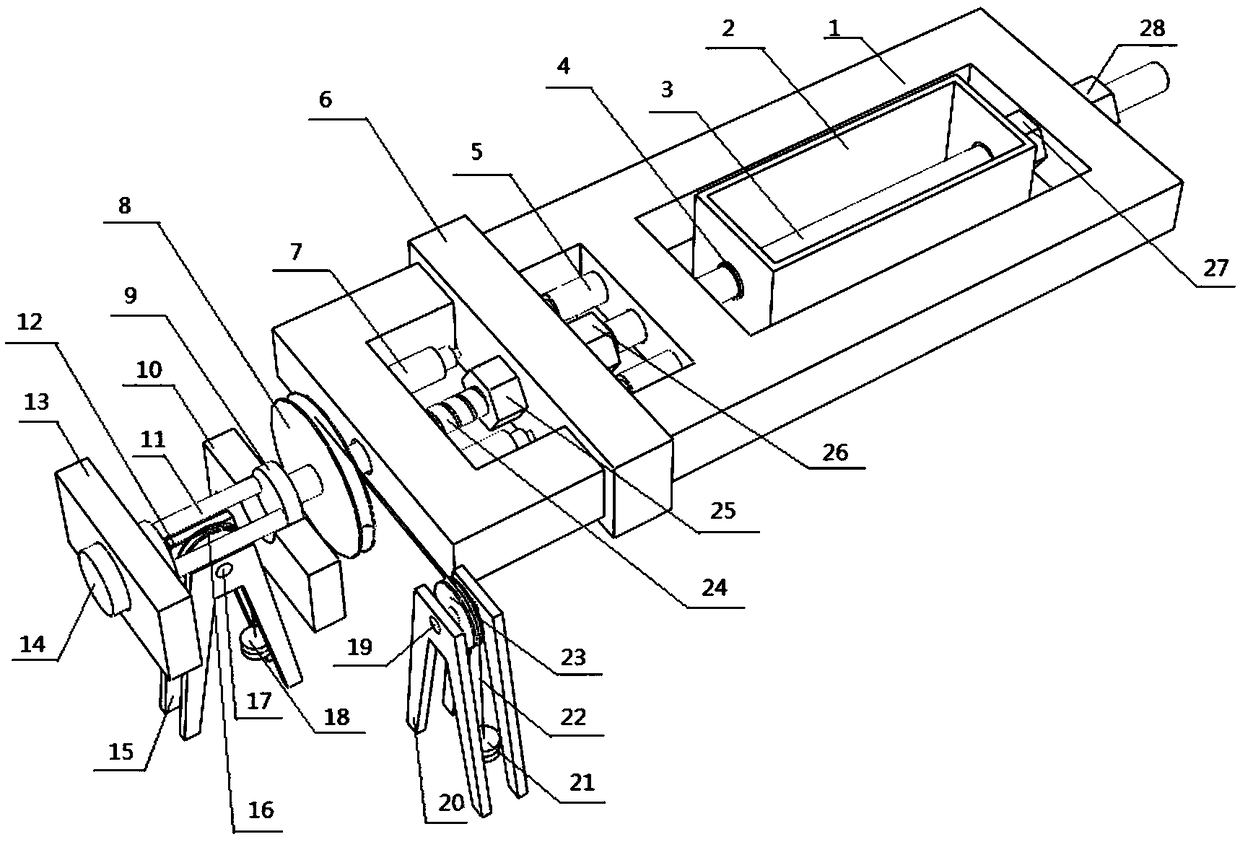

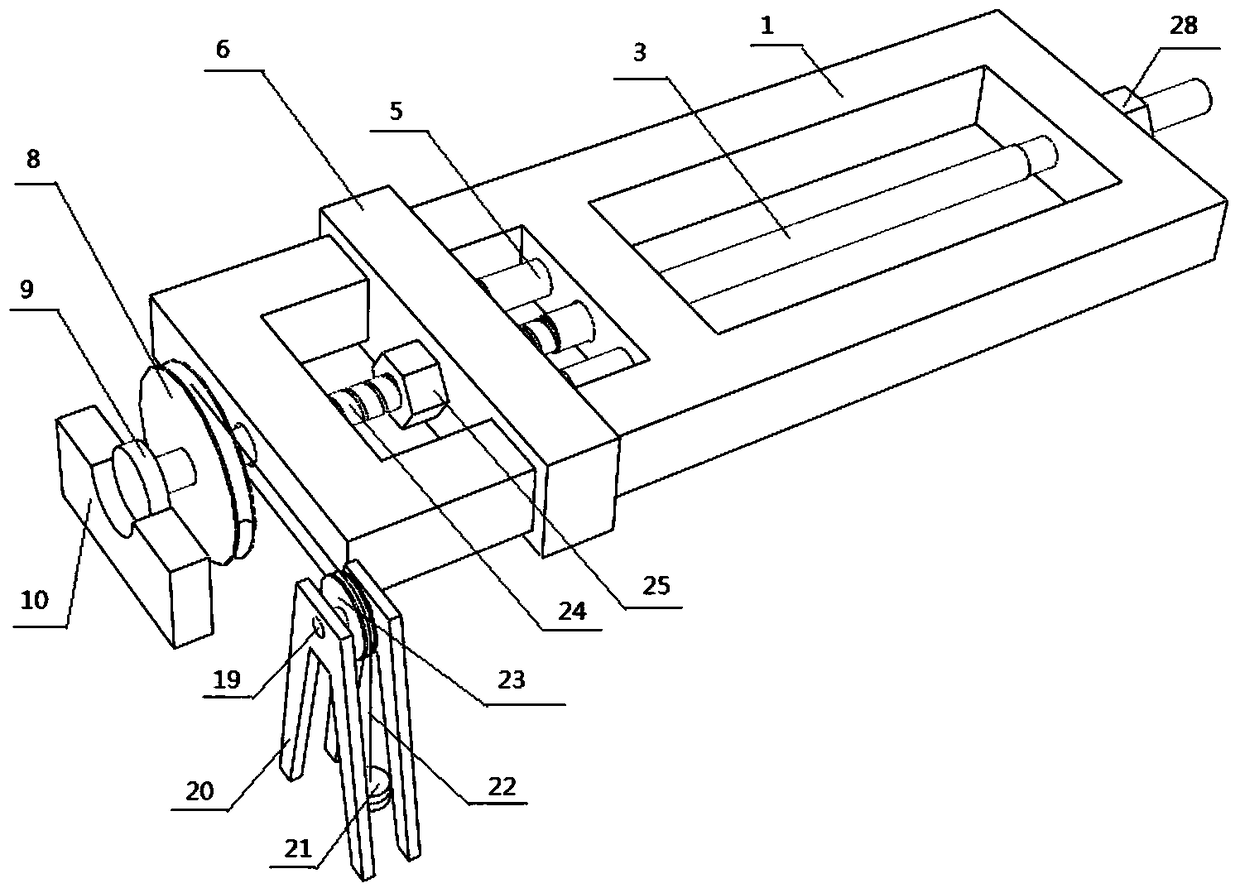

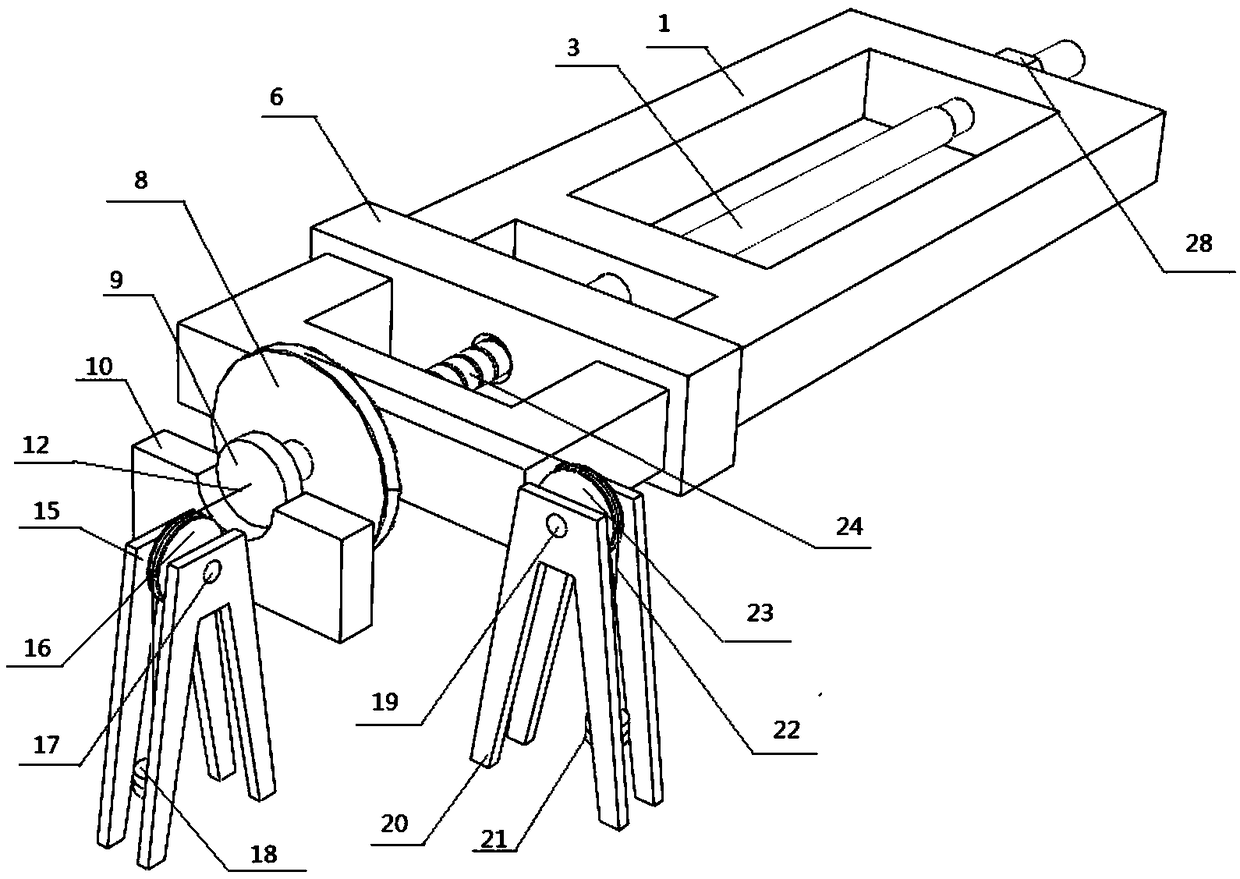

[0024] like figure 1 As shown, the deep-sea pipeline stress corrosion complex loading test device mainly includes: overall frame and fixed support 1, 10, PVC corrosion water tank 2, test pipe fitting 3, rubber gasket 4, constant displacement tension and compression loading modules 5-7, 24-28 , constant torsional load loading modules 8, 19-23, constant compressive load loading modules 9, 11-18.

[0025] like figure 1 As shown, the PVC corrosion water tank 2 is used to store corrosive liquids, and the PVC plastic tank is used to avoid the influence of other ions. The opening on the box wall is sealed by a rubber gasket 4. According to the needs of the test can be used separately Figure 2-5 composite loading mechanism.

[0026] When performing constant displacement tension torsion coupling loading stress corrosion simulation, you can use fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com