Purification treatment process for waste plastic washing wastewater

A technology for purifying and treating waste plastics, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

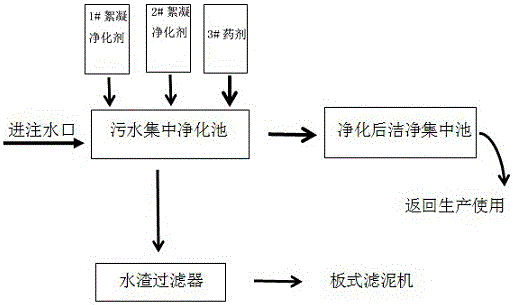

[0029] Examples such as figure 1 Shown, a kind of purification treatment process of waste plastic washing sewage, comprises the following steps:

[0030] 1. The stirring step is to discharge the washing sewage into the purification tank. Taking the length of the pool * width * depth = 4 meters * 4 meters * 2 meters as an example, the depth of sewage injection is 1.6 meters. When the sewage is injected into 1.6 meters, stop injecting sewage and start The mixing pump is used for mixing. The mixing pump is a submersible slurry pump mixer. The submersible slurry pump mixer is used, which has less investment, is easy to manufacture, and has a uniform flow rate of mixing water.

[0031] 2. Flocculation and sedimentation steps:

[0032] A. The first flocculation and sedimentation step

[0033] Add 1# flocculation purification agent in proportion, 1# flocculation purification agent is polyacrylamide, the addition amount is 8 / 100,000 of the sewage weight, stir to obtain preliminary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com