Oil return bottle mouth

A technology for returning oil bottles and oil bottles, which is applied in the field of oil bottle nozzles, can solve the problems of oil loss along the outer wall, pollution, etc., and achieves the effect of cheap price, simple operation technology, and wide user population

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Owing to having adopted above-mentioned scheme, the present invention is implemented in the following manner in conjunction with accompanying drawing:

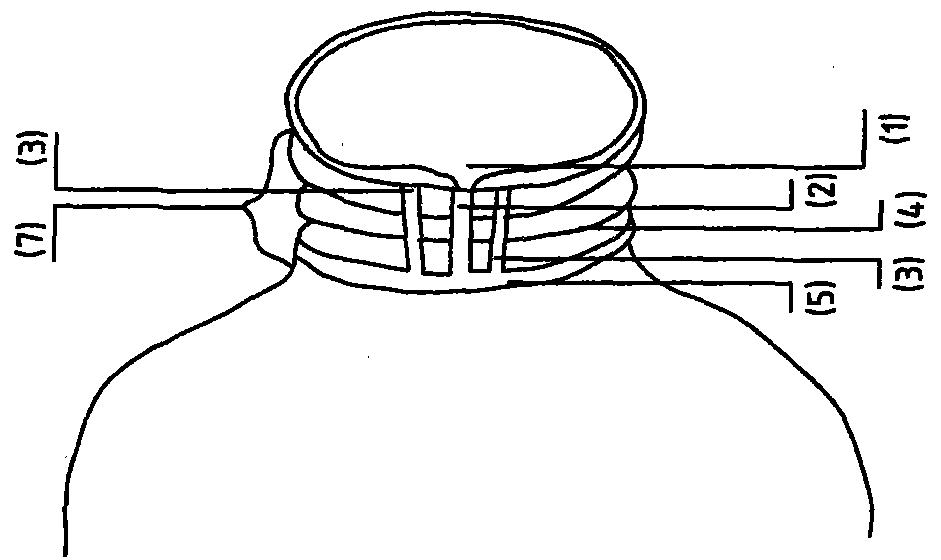

[0013] 1. The mouth (neck) of the oil return bottle is cylindrical, which is conducive to sealing with a cap. The fixed part of the oil outlet of the oil return bottle is set in the shape of a bird's beak figure 1 (1), it facilitates oil flow out and return to the oil tank figure 1 The positions of (2), (3) are fixed and easy to use. figure 1 (2) It is the main oil return groove, the groove is deeper, it can prevent the oil from spreading; figure 1 (3) is attached back to the oil tank, it and figure 1 (2) Adjacent to each other, the groove is shallower, which is used to prevent the spread of very little oil that is not blocked by the main oil return tank, and can completely prevent the spread of oil and flow into the oil return pan smoothly.

[0014] 2. Oil return tray figure 1 (5), the groove in the plate has a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com