Fixed-position quantitative material delivery device and method

A material and installation technology, applied in transportation and packaging, multi-axis trolleys, trolleys, etc., to achieve the effect of improving work efficiency, reducing production abnormalities, and reducing time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

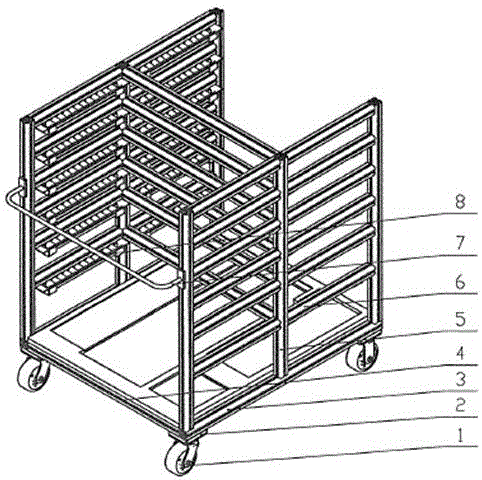

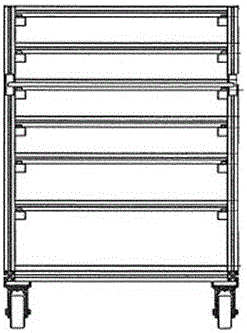

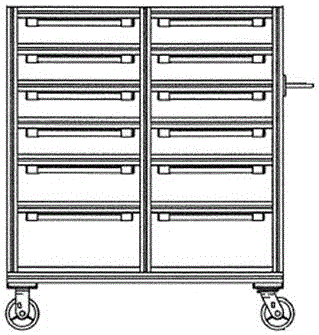

[0027] Please refer to Figure 1 to Figure 7, a fixed quantitative material distribution device, the device is a cart, including four universal wheels 1, universal wheel mounting plate 2, bottom support frame 3, tray 4, six pillar beams 5, twenty-four horizontal connection Beam 6, six beams, handrail 7 and fluent bar 8. The support frame on the bottom surface, the pillar beams, and the horizontal connecting beams constitute the skeleton of the cart, forming an overall frame. According to the different materials to be distributed, the storage space of the entire trolley is divided into 12 storage areas of different sizes through the pillar beams and horizontal connecting beams. A fluent strip is installed correspondingly on the surface of each horizontal connecting beam, so that the matching tray can slide freely on the surface for easy access. Several storage areas of different sizes are formed between the pillar beams and the horizontal connecting beams, and the fluent stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com