A kind of manufacturing method of the air pineapple cultivation base made of kudzu root fiber

A technology of kudzu root fiber and air pineapple, which is applied in the direction of culture medium, planting substrate, botanical equipment and methods, etc., can solve the problems of no air pineapple planting utensils, etc., and achieve the effect of colorful, convenient production, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

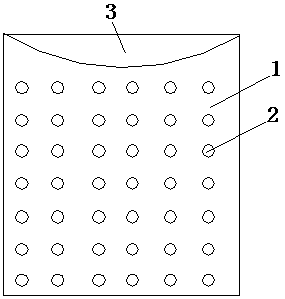

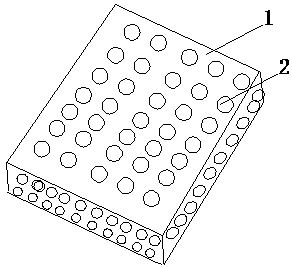

[0020] Embodiment 1, the cultivation base of Tillandsia pineapple includes a cultivation body and such as dry ventilation holes 2 arranged on the cultivation body 1 , and a display pit 3 is arranged on the top of the cultivation body 1 .

[0021] A pineapple culture base made of kudzu root fiber is characterized in that it is composed of the following raw materials in parts by weight: kudzu root 60-80, perlite 10-15, straw fiber 15-20, sweet potato starch 8-10, clay 30- 40. Cinder 7-8, appropriate amount of water;

[0022] The preparation method of the described pineapple cultivating base made of kudzu root fiber comprises the following steps:

[0023] 1) Production of kudzu root fiber: fresh kudzu root is crushed whole, washed in water to remove starch,

[0024] After removal, soak in water for more than 2 hours. After soaking, add 0.3% to 1.2% cellulase for biolysis, adjust the pH to 5 to 7, and let it stand for 6 to 8 hours. Take it out, drain it, and put it into a drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com