Electronic product, glass shell and manufacturing equipment and method thereof

A technology for glass shells and manufacturing methods, applied in glass manufacturing equipment, glass pressing, electrical equipment shells/cabinets/drawers, etc., can solve the problems of glass shells being fragile, reduce the risk of cracking, and improve the overall strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

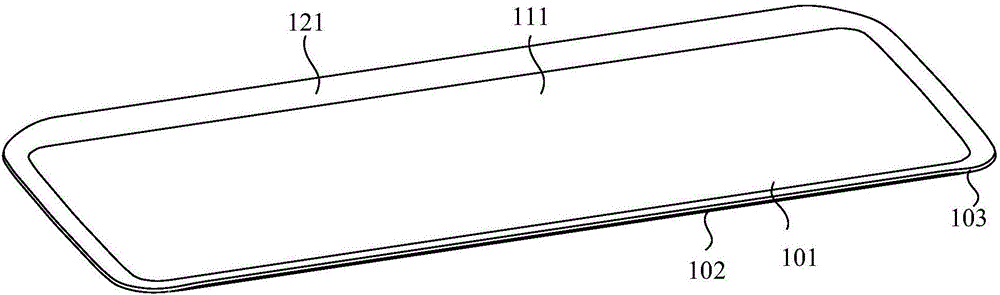

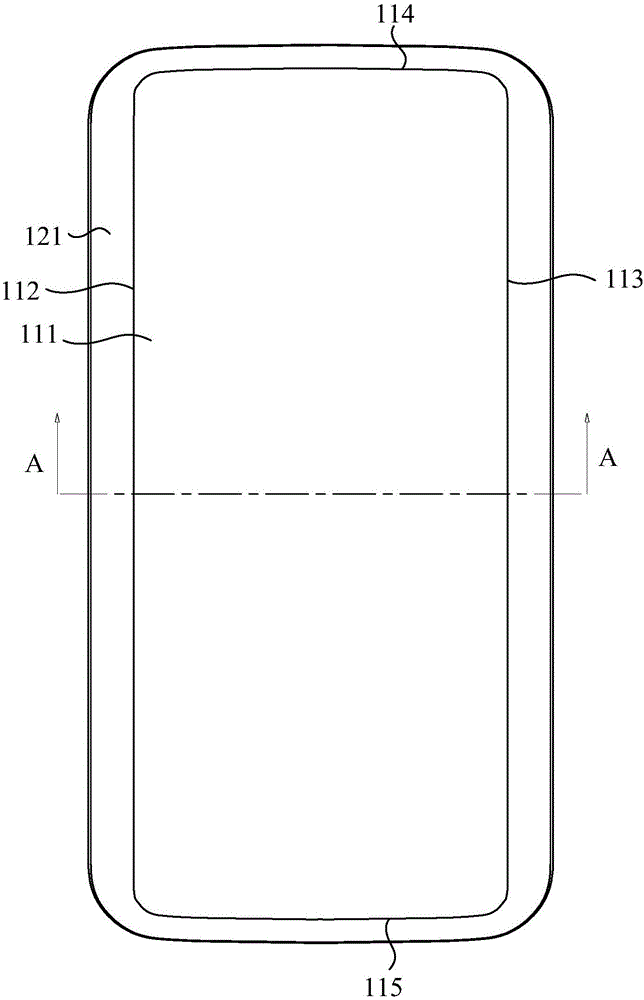

[0035] Such as Figure 1-Figure 4 As shown in , an embodiment of the present invention provides a glass case, which can be applied to electronic products such as smart phones, and can be used as a case for the display surface of a mobile phone or the like, and can also be used as a cover for the back of a mobile phone or the like.

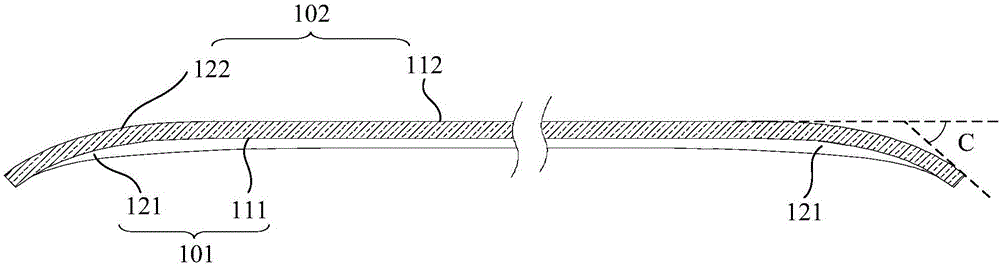

[0036] The glass envelope includes an inner surface 101 , an outer surface 102 spaced apart from the inner surface 101 , and a side peripheral surface 103 connecting the outer surface 102 and the inner surface 101 .

[0037] The inner surface 101 includes a planar portion 111 and a curved portion 121 bent and extended from a periphery of the planar portion 111 toward one side. The curved surface 121 is an arc curved surface. The arc radius of the curved portion 121 is 1-50 mm, preferably 5-50 mm, more preferably 5-20 mm, more preferably 5-10 mm. The smaller the radius is, the steeper the arc surface is, so the formed glass shell has a stronger 3D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com