Switch of electric appliance provided with electrical heating element and electric appliance

A technology of electric heating elements and switches, applied in electric switches, electrical elements, circuits, etc., can solve the problems of virtual connection, complexity, and unprotected switches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

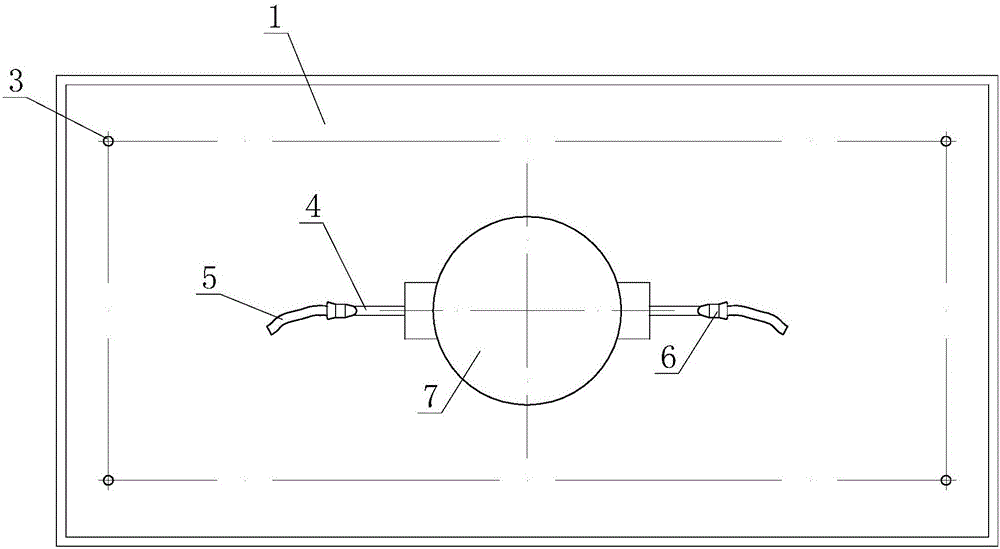

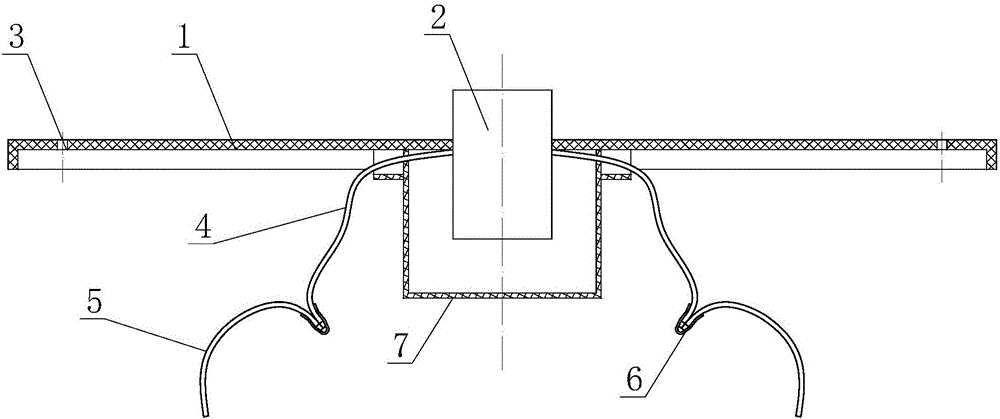

[0030] figure 1 It is the front view of the switch of embodiment 1; figure 2 Yes figure 1 Cutaway view.

[0031] In the figure, the meaning of each reference sign is as follows:

[0032] 1. Switch mounting plate; 2. Switch body; 3. Mounting hole; 4. Class A conductor; 5. Class B conductor; 6. Insulation connection cap; 7. Flame retardant box.

[0033] A switch for an electrical appliance with electric heating elements, comprising a switch mounting plate 1, a switch body 2 is mounted on the switch mounting plate 1, and the switch mounting plate 1 is provided with a plurality of switches for mounting the switch mounting plate 1 in a detachable manner Mounting hole 3 on the outer wall of the appliance.

[0034] By setting the switch mounting plate 1 to be detachably installed on the outer wall of the appliance, when the switch fails or is damaged, the switch mounting plate 1 can be directly removed from the outer wall of the appliance, and then removed from the switch mounting plate 1. ...

Embodiment 2

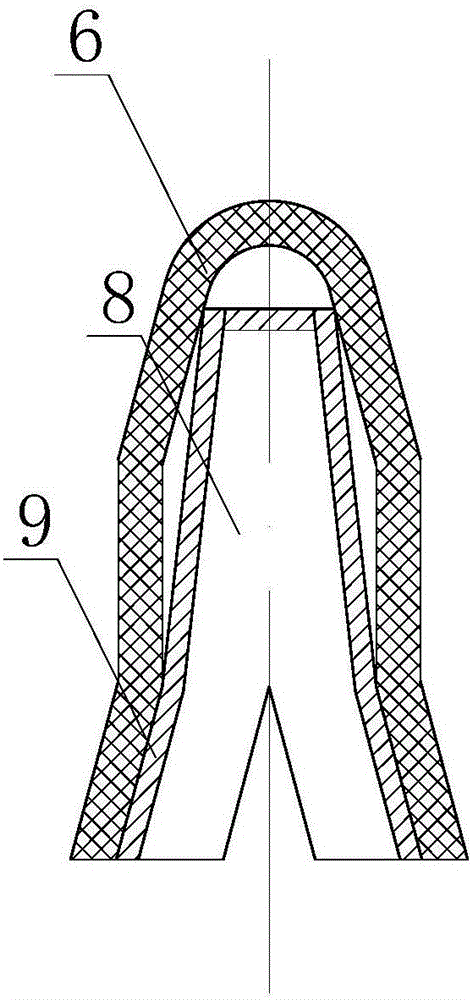

[0042] image 3 Is a cross-sectional view of part 6 of the insulating connecting cap in embodiment 2; Figure 4 Is a three-dimensional schematic diagram of the memory alloy connecting sleeve in embodiment 2; Figure 5 It is a schematic diagram of the shape of the shape memory alloy connecting sleeve deformed after heating. In the figure, the meaning of each reference sign is as follows:

[0043] 8. Base plate; 9. Side wall.

[0044] The difference between this embodiment and embodiment 1 is:

[0045] Preferably, the insulating connection cap 6 is provided with a memory alloy connection sleeve. The memory alloy connection sleeve includes a Y-shaped substrate 8. Both sides of the substrate 8 are provided with side walls 9 respectively. The class wire 4 and the class B wire 5 are adjacent, the height of the side wall 9 is greater than half of the larger diameter of the connected class A wire 4 and the class B wire 5, and the side walls 9 on both sides are at the temperature of the memo...

Embodiment 3

[0049] Image 6 Is a three-dimensional schematic diagram of the memory alloy connecting sleeve in embodiment 3; Figure 7 It is a schematic diagram of the shape of the shape memory alloy connecting sleeve deformed after heating. In the figure, the same reference numerals as those used in the drawings in the foregoing embodiment still use the definition of the reference numerals in the foregoing embodiment, and the new reference numerals in the figures indicate the following meanings:

[0050] 10. Top plate.

[0051] Further preferably, the memory alloy connecting sleeve further includes a top plate 10, and the top plate 10 is connected to a side wall 9 respectively.

[0052] By setting the top plate 10, the upper part of the Class A wire 4 and the Class B wire 5 can be sealed. When the two side walls 9 shrink together, the Class A wire 4 and the Class B wire 5 will not be squeezed out of the memory alloy to connect The sleeve prevents the two wires from being separated and ensures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com