A lifting method applied to large caisson

A caisson, jacking technology, applied in caisson, construction, infrastructure engineering and other directions, can solve the problems of strong jacking airbag pressure, hidden dangers, small weight of jacking caisson, etc., to improve jacking height, strong practicability, The effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

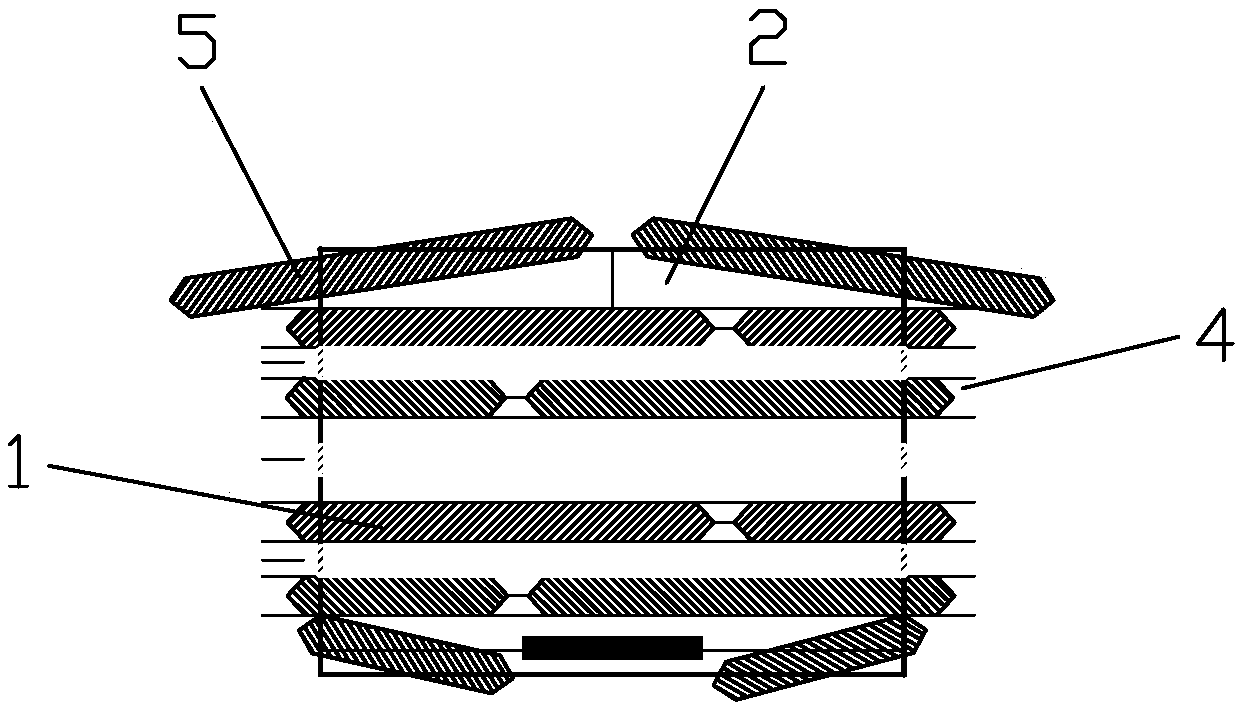

[0056] For another example 2, refer to figure 1 , a jacking method applied to a large caisson, comprising the following steps:

[0057] 1). Lay the main airbag 1: on the prefabrication field 3 that conforms to the prefabrication of the caisson 2, according to the size of the prefabricated caisson 2, arrange four airbag grooves 4 at the predetermined position below the caisson 2. The width of the airbag groove 4 is 1.1m. The height is 20cm, and the main airbag 1 is laid in the airbag ditch 4;

[0058] 2). Initial jacking: Inflate the main airbag 1 in the airbag ditch 4, the air pressure of the main airbag 1 near the front side of the caisson 2 is higher than the inflation pressure of the main airbag 1 near the rear side of the caisson 2, so that the front side of the caisson 2 Lift 15cm;

[0059] 3). Lay the auxiliary airbag 5 on the front side: lay the auxiliary airbag 5 in the gap between the front side of the caisson 2 and the prefabrication yard 3, and inflate the auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com