Skinning machine scrap pressing mechanism and working method thereof

A peeling machine and embossing technology, which is applied in the field of advanced manufacturing and automation, can solve the problems of damage to the peeling knife, affect the efficiency and progress of production, and affect the service life of the peeling knife, and achieve the effect of shortening the cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

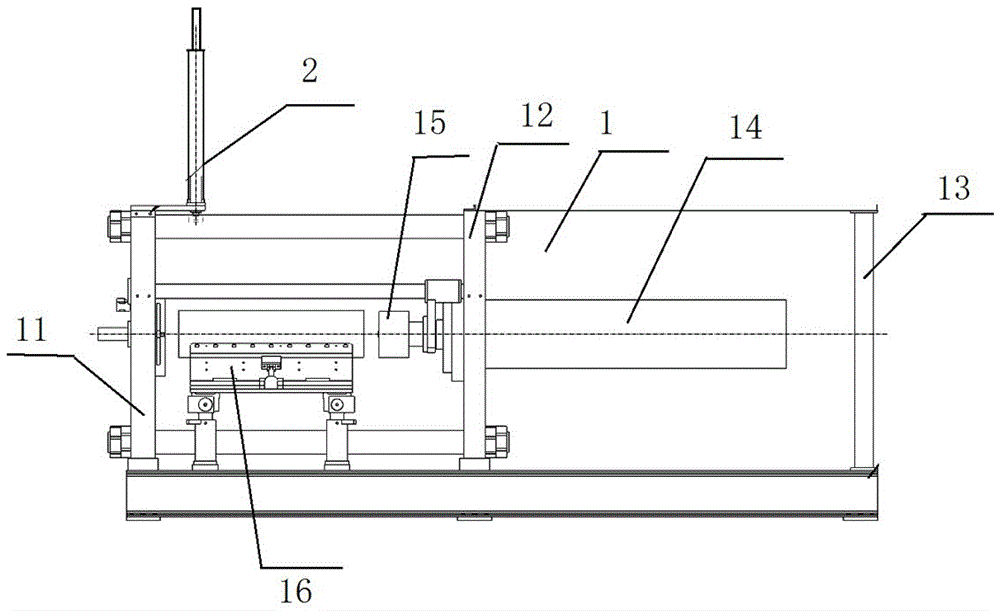

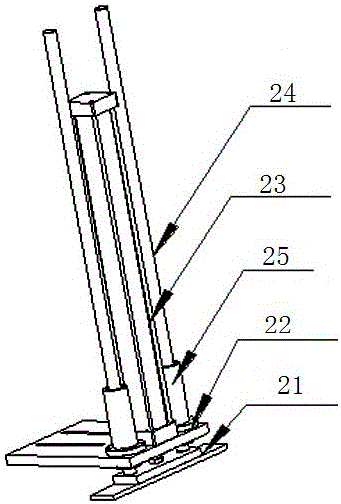

[0035] like figure 1 and figure 2 A kind of embossing mechanism for peeling machine shown, comprises: peeling machine 1, embossing mechanism 2, wherein, described embossing mechanism 2 is provided with pressing plate 21, fixed plate 22, linear power source 23 and double Guide rod 24, a base frame and a control device are provided in the described peeling machine 1, and a front beam 11, a middle beam 12 and a rear beam 13 are sequentially arranged on the described base frame from front to back,

[0036] The relationship between the above components is as follows:

[0037] Described pressing plate 21 is located at the below of fixed plate 22, and described fixed plate 22 one end is fixed with pressing plate 21, and the other end is with the push plate of peeling machine 1 single peeling machine 1, and described linear power source 23 is located at fixed. Above the plate 22, the double guide rods 24 are arranged on both sides of the linear power source 23, and the double guide...

Embodiment 2

[0046] The embossing mechanism described in the working method for the embossing mechanism of the peeling machine described in this embodiment is the same as that in Embodiment 1.

[0047] like figure 1 and figure 2 A kind of embossing mechanism for peeling machine shown, comprises: peeling machine 1, embossing mechanism 2, wherein, described embossing mechanism 2 is provided with pressing plate 21, fixed plate 22, linear power source 23 and double Guide bar 24, described peeling machine 1 is provided with base frame 11 and control device, described base frame 11 is provided with front beam 11, middle beam 12 and rear beam 13 successively from front to back,

[0048] The relationship between the above components is as follows:

[0049] Described pressing plate 21 is located at the below of fixed plate 22, and described fixed plate 22 one end is fixed with pressing plate 21, and the other end is with the push plate of peeling machine 1 single peeling machine 1, and described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com