A method for producing hot-rolled seamless steel pipes with a twin-mandrel combined rolling mill

A technology of seamless steel pipes and double mandrels, applied in metal rolling and other directions, can solve the problems of low production efficiency, small wall reduction, low yield, etc., to improve production efficiency and quality, low production cost, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

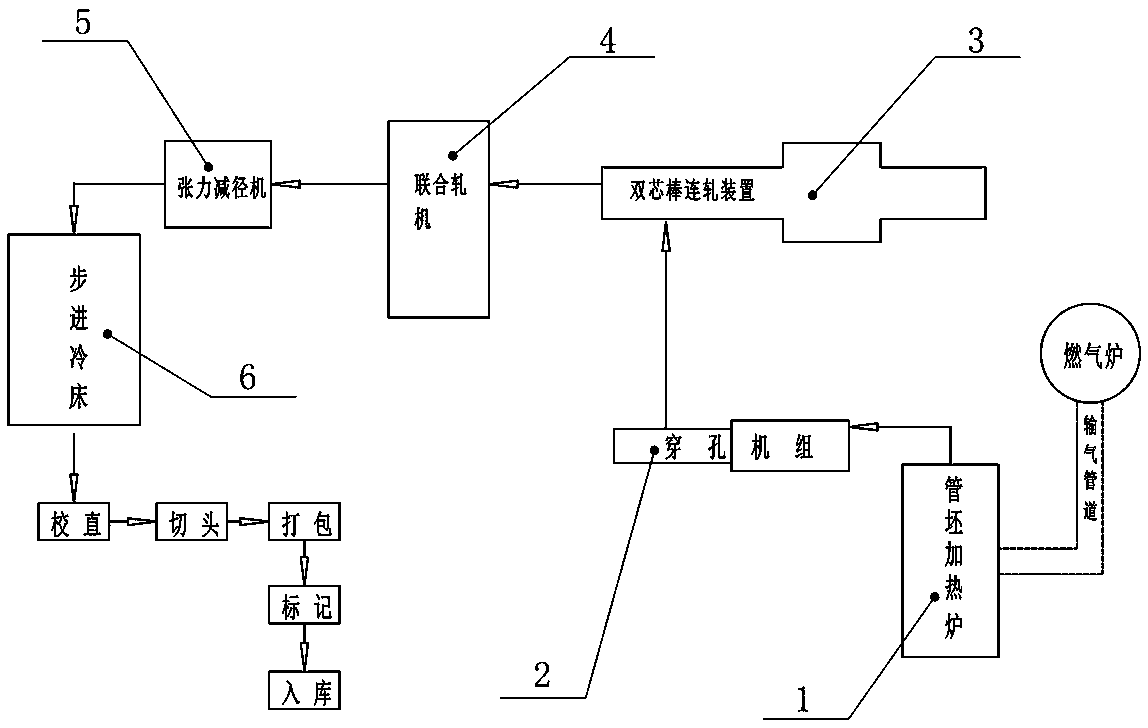

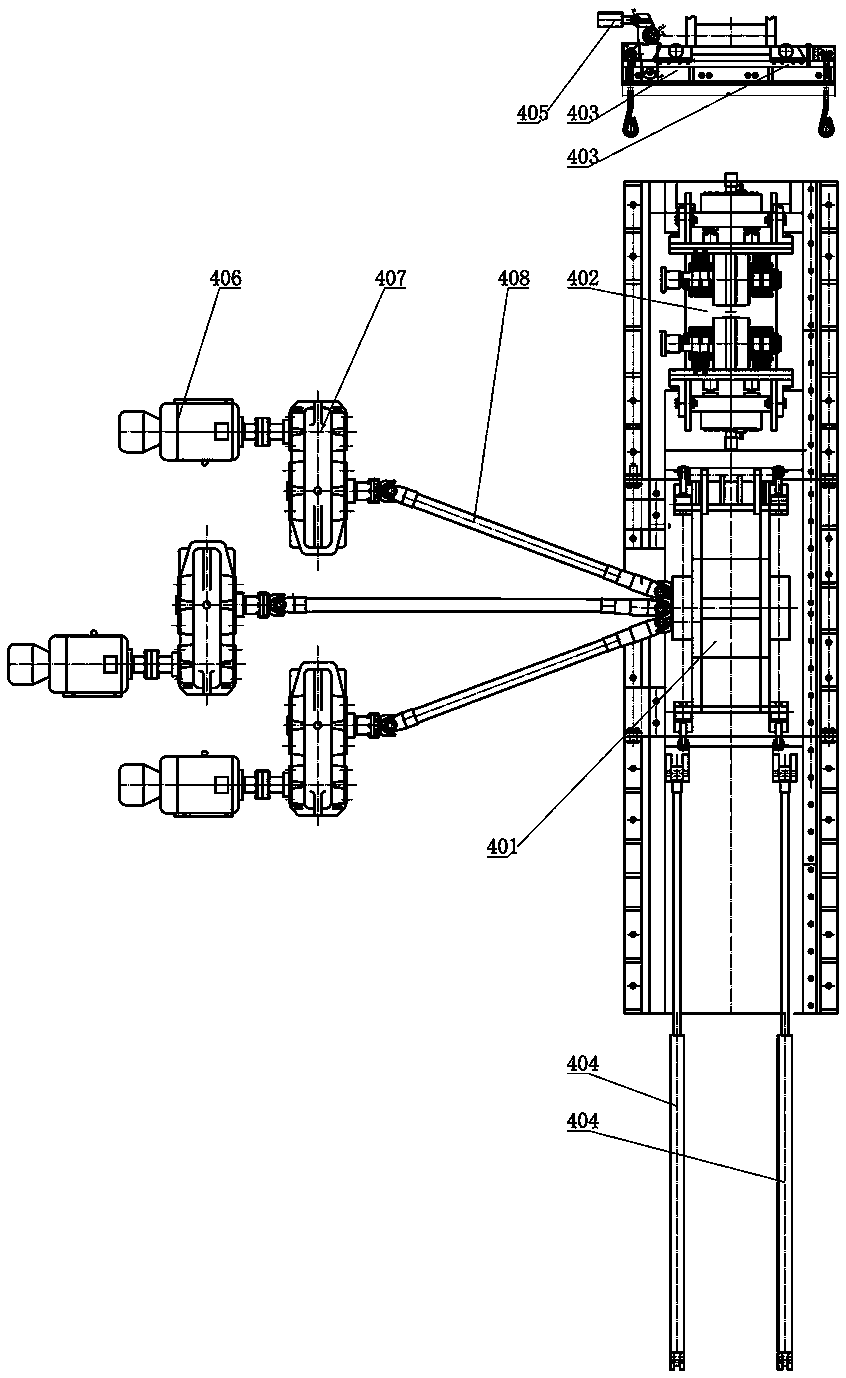

[0032] A method for producing hot-rolled seamless steel pipes in a twin-mandrel combined rolling mill, such as figure 1 , 2 As shown, the specific steps are as follows:

[0033] Step 1) heating, the tube blank is heated in the tube blank heating furnace 1, and the heating temperature is 1150°C;

[0034] Step 2) Piercing, the heated tube blank is pierced by the piercing unit 2 to make a capillary tube;

[0035] Step 3) The double-mandrel continuous rolling device 3 pierces the rod, and the perforated capillary is turned into the telescopic feeding platform of the double-mandrel continuous rolling device 3, and the telescopic feeding platform is driven to move by the moving platform back and forth, so that The capillary flows into the rotary feeding mechanism of the twin-mandrel continuous rolling device 3 for pre-piercing the mandrel;

[0036]Step 4) Rolling, the capillary tube with the mandrel is selected into the combined rolling mill 4 by the rotary feeding mechanism of t...

Embodiment 2

[0041] A method for producing hot-rolled seamless steel pipes in a twin-mandrel combined rolling mill, such as figure 1 , 2 As shown, the specific steps are as follows:

[0042] Step 1) heating, the tube blank is heated in the tube blank heating furnace 1, and the heating temperature is 1200°C;

[0043] Step 2) Piercing, the heated tube blank is pierced by the piercing unit 2 to make a capillary tube;

[0044] Step 3) The double-mandrel continuous rolling device 3 pierces the rod, and the perforated capillary is turned into the telescopic feeding platform of the double-mandrel continuous rolling device 3, and the telescopic feeding platform is driven to move by the moving platform back and forth, so that The capillary flows into the rotary feeding mechanism of the twin-mandrel continuous rolling device 3 for pre-piercing the mandrel;

[0045] Step 4) Rolling, the capillary tube with the mandrel is selected into the combined rolling mill 4 by the rotary feeding mechanism of ...

Embodiment 3

[0050] A method for producing hot-rolled seamless steel pipes in a twin-mandrel combined rolling mill, such as figure 1 , 2 As shown, the specific steps are as follows:

[0051] Step 1) heating, the tube blank is heated in the tube blank heating furnace 1, and the heating temperature is 1200°C;

[0052] Step 2) Piercing, the heated tube blank is pierced by the piercing unit 2 to make a capillary tube;

[0053] Step 3) The double-mandrel continuous rolling device 3 pierces the rod, and the perforated capillary is turned into the telescopic feeding platform of the double-mandrel continuous rolling device 3, and the telescopic feeding platform is driven to move by the moving platform back and forth, so that The capillary flows into the rotary feeding mechanism of the twin-mandrel continuous rolling device 3 for pre-piercing the mandrel;

[0054] Step 4) Rolling, the capillary tube with the mandrel is selected into the combined rolling mill 4 by the rotary feeding mechanism of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com