Novel efficient filtering plate

A filter plate, high-efficiency technology, applied in the direction of filtration and separation, dispersed particle filtration, fixed filter element filter, etc., can solve the problems of unfavorable use, difficult installation and tightness, blocking fluid circulation, etc., to improve the convenience of use and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

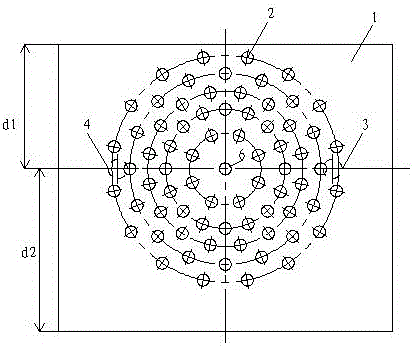

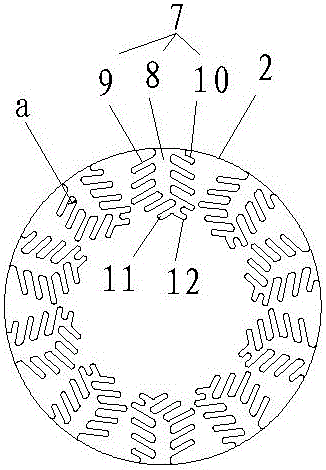

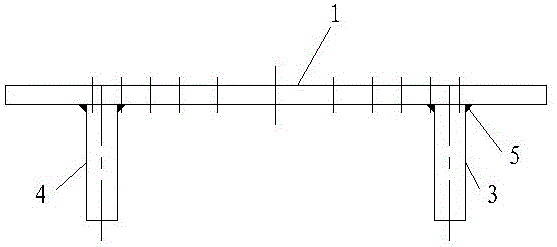

[0022] A new type of high-efficiency filter plate, including a filter plate body, the filter plate body is provided with a number of filter holes, wherein, the bottom of the filter plate body is provided with a first support column and a second support column, and the first support column and the second support column are located on both sides of the filter plate body, and are vertically connected to the filter plate body. Sealing glue is provided between the first support column and the second support column and the filter plate body, and several filter holes include a central filter plate body. Holes, and around the central filter hole in several layers of annular distribution;

[0023] The vertical distance from the central filter hole to one side of the filter plate body is d1, and the vertical distance from the central filter hole to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com