Breathing simulator for calibrating spirometer

A lung function instrument and simulator technology, applied in the field of respiratory simulators, can solve the problems of inaccurate piston movement, unsatisfactory calibration effect, and insufficient piston movement, so as to facilitate gas entry and exit, prevent screw rod skewing, and smooth piston movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

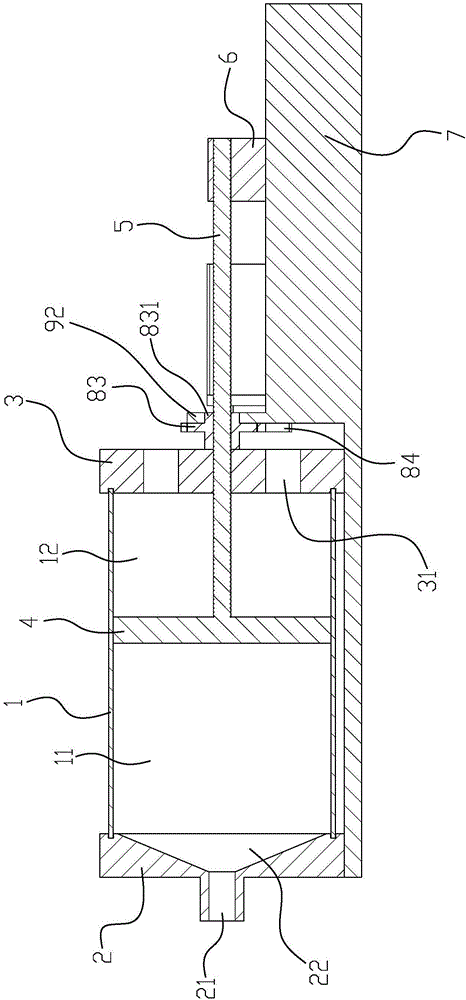

[0031] Please refer to figure 1 and figure 2 , a respiratory simulator for calibrating lung function apparatus according to the present invention, comprising: a cylinder body 1, a front end cover 2, a rear end cover 3, a piston 4, a screw rod 5, a limit block 6, and a servo drive mechanism. The cylinder body 1 is arranged axially, and the cylinder body 1 is a sleeve structure with openings at both axial ends. The front end cover 2 is used to cover the opening at one end of the cylinder body 1 , and the front end cover 2 is provided with an air outlet 21 . The rear end cover 3 is used to cover the opening at the other end of the cylinder body 1 , and the rear end cover 3 is provided with an exhaust hole 31 . The piston 4 is movably arranged in the cylinder body 1 , and the piston 4 divides the inner space of the cylinder body 1 into a left air chamber 11 and a right air chamber 12 in the axial direction. The screw rod 5 is axially arranged, and one end of the screw rod 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com