Multi-purpose highland clearance field management machine

A multi-purpose, high-ground-gap technology that is applied to agricultural machinery and implements, devices for catching or killing insects, etc., can solve problems such as limited working range, limited working capacity, and single function, and achieve operation and maintenance Simple maintenance, long service life and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

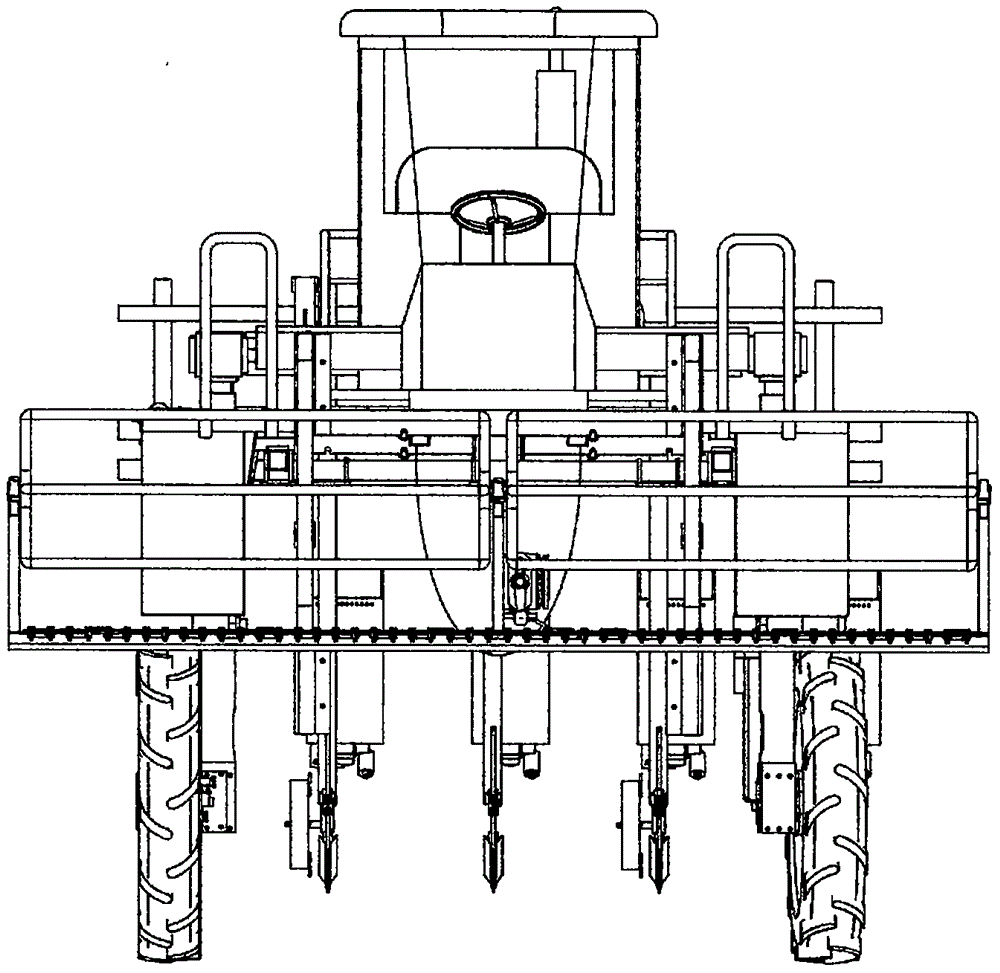

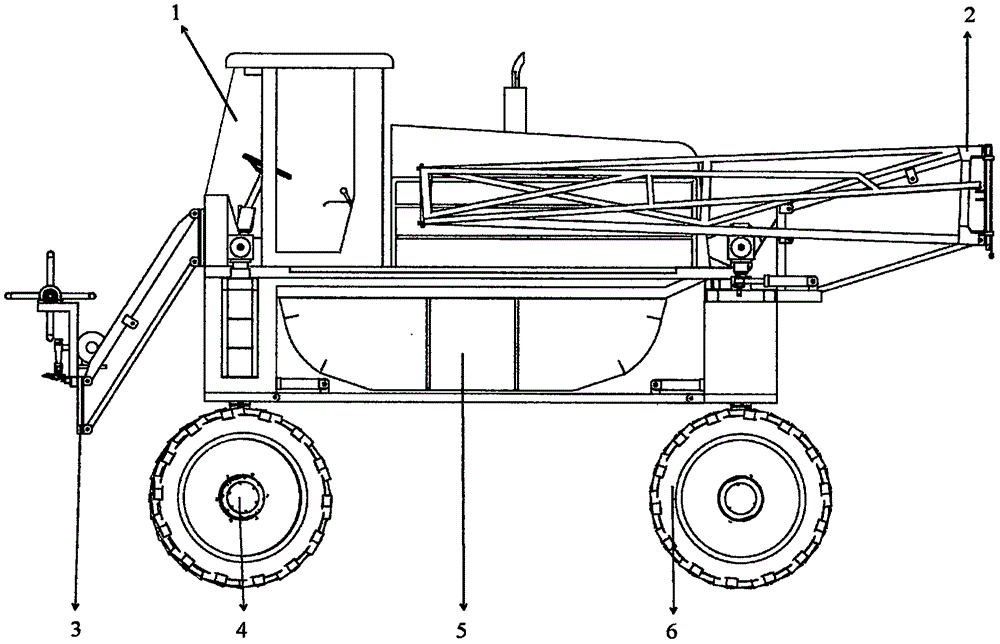

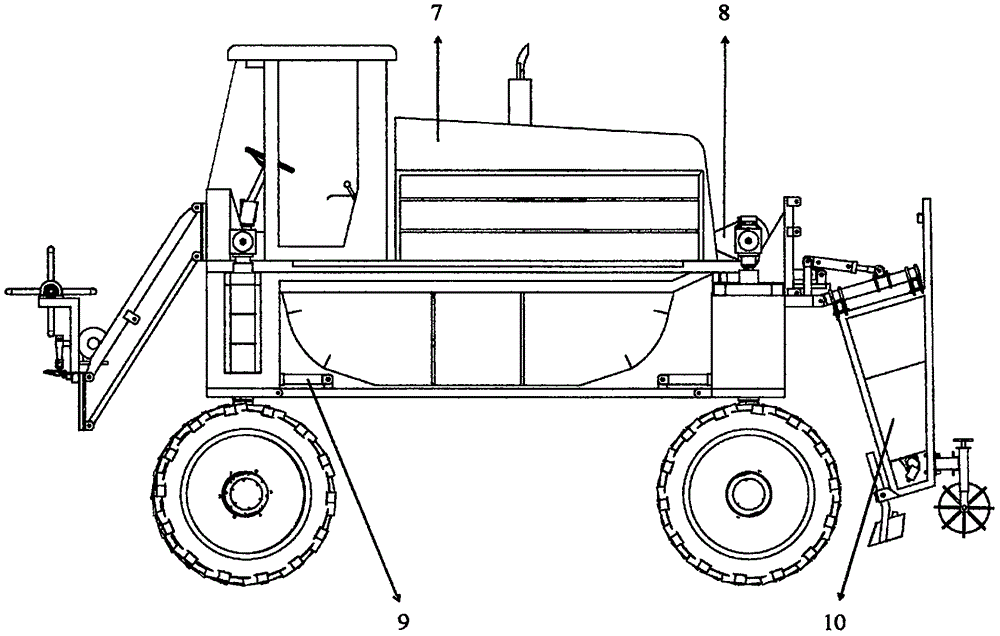

[0020] The preferred embodiment of the present invention is described in detail below in conjunction with accompanying drawing, one machine multi-purpose high clearance field management machine consists of: driver's cab 1, spray boom frame 2, top cutter 3, wheel edge reducer 4, liquid tank 5, wheel 6 , car body cover 7, transmission axle with differential lock 8, hydraulic cylinder 9, fertilizer applicator 10, power reversing box 11, front and rear column connecting frame 12, crossbeam 13, belt steering transmission column 14, liquid fertilizer fertilizer applicator 15 .

[0021] It is characterized by

[0022] In the mechanical walking system, the engine cooperates with the gearbox, the gearbox cooperates with the transfer case, the transfer case cooperates with the front and rear transmission axles with differential locks 8, and the front and rear transmission axles with differential locks 8 cooperate with the power reversing box 11. The power reversing box 11 cooperates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com