Gap adjustment mechanism between devices in cabinet

A technology for equipment rooms and cabinets, applied in the field of clearance adjustment mechanisms, can solve the problems of assembling workpieces, many processes, inability to adjust, and difficulty in ensuring that they are assembled in one piece, etc., to increase the adjustment range, reduce production costs, and be simple and convenient to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

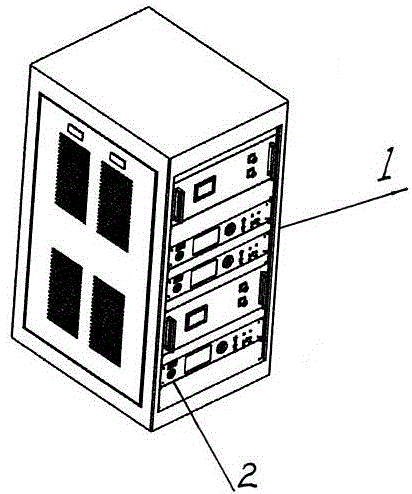

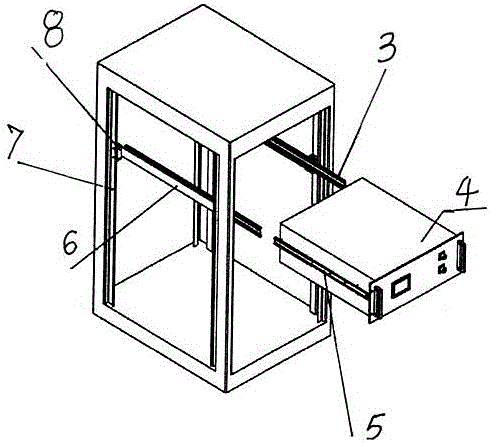

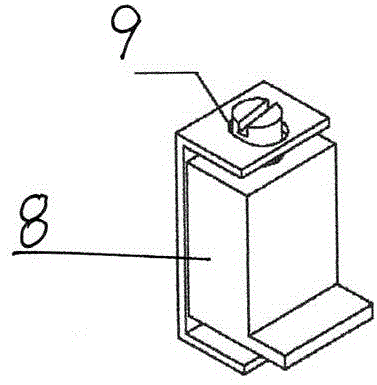

[0011] The gap adjustment mechanism between the equipment is composed of cabinet 1, adjustment unit 8, column 7, supporting plate 6, and pullable guide rails. The specific implementation is as follows figure 1 with figure 2 As shown, the equipment 4 is installed layer by layer in the cabinet 1, and the installation gap 13 between the upper and lower adjacent panels 2 of each layer of equipment is 0.8 mm. In order to adjust the gap between the equipment and realize large-scale vertical and horizontal adjustments, Specific implementation methods such as image 3 , 4 As shown, the adjustment unit 8 is composed of an oblong hole 9, a fixing frame 10, an adjusting screw 11 and an adjusting screw block 12. The upper and the bottom of the fixing frame are processed with an oblong hole 9, and the adjusting screw 11 is equipped with an adjusting screw block 12. The upper and lower ends of the adjusting screw go through the oblong hole and the adjusting block is seated in the fixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com