Assembly-type optical fiber distribution frame

An optical fiber distribution frame and assembled technology, which is applied in the field of assembled optical fiber distribution frame, can solve the problems of difficult maintenance, inconvenient engineering installation, complicated welding process, etc., and achieve the effect of convenient transportation, convenient engineering installation and accurate structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

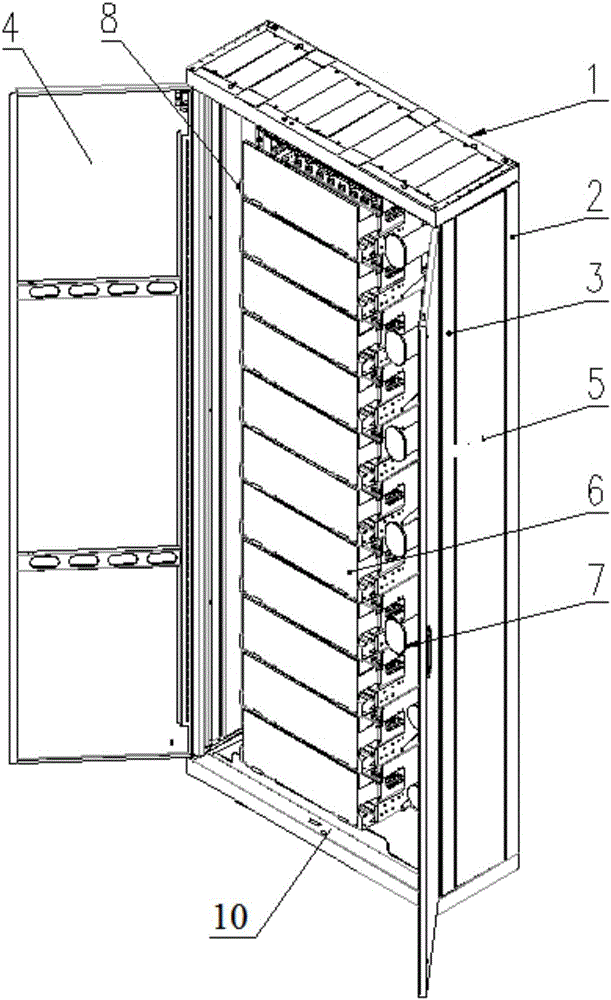

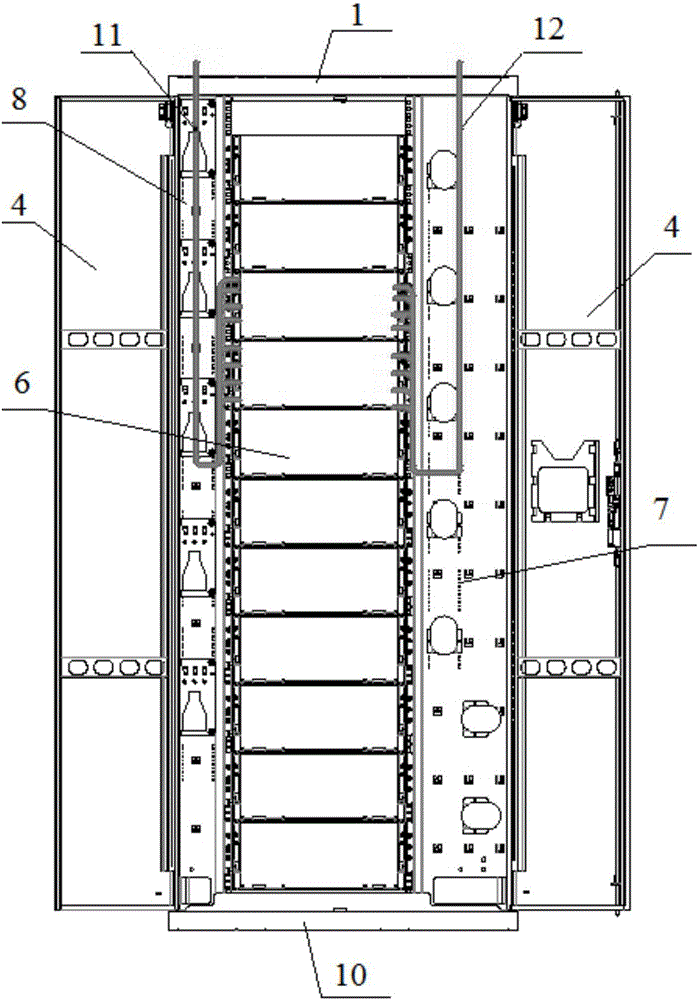

[0024] refer to figure 1 As shown, an assembled optical fiber distribution frame is disclosed in this embodiment, and its box structure mainly includes a top plate 1, a bottom plate 10 opposite to the above-mentioned top plate 1, and is arranged between the above-mentioned top plate 1 and the bottom plate 10 and connected to the two Two vertical one-piece rear pillars 2, two front pillars 3 that are arranged between the above-mentioned top plate 1 and the bottom plate 10 and are perpendicular to the two, and the side that is arranged between the above-mentioned one-piece rear pillar 2 and the above-mentioned front pillar 3 Plate 5, the above-mentioned top plate 1, bottom plate 10, integrated rear column 2, front column 3, and side panels 5 form the main body of the optical fiber distribution frame with accommodating space, that is, the box structure, and the two above-mentioned front columns 3 pass through Movable spring latch is connected with door panel 4, and above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com