Grain flow measurement device and method based on opposite laser emission type array sensors

An array sensor and laser beam-to-beam technology, which is used in measuring devices, measuring flow/mass flow, and liquid/fluid solids measurement. , the probe is easy to accumulate dust and the measurement accuracy, etc., to shorten the research and development cycle, improve the accuracy and stability, and reduce the measurement error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

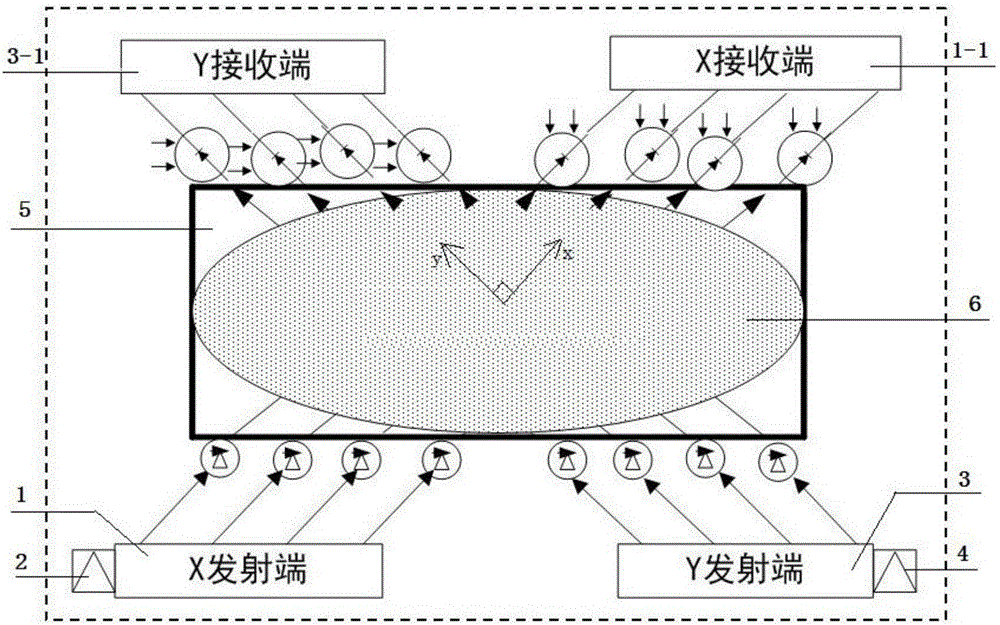

[0047] The invention proposes a laser array type grain flow measurement device and method, which overcomes the problems of uneven grain distribution on the scraper and large dust accumulation measurement error of the traditional photoelectric sensor. Scraper grain distribution to reproduce.

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

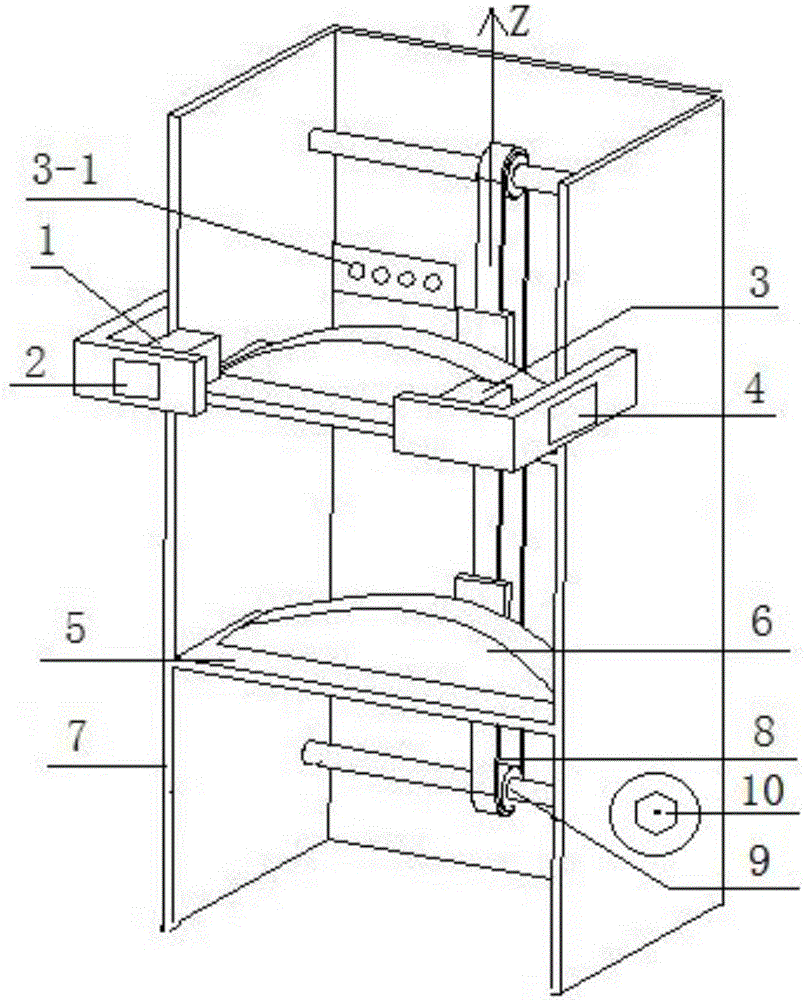

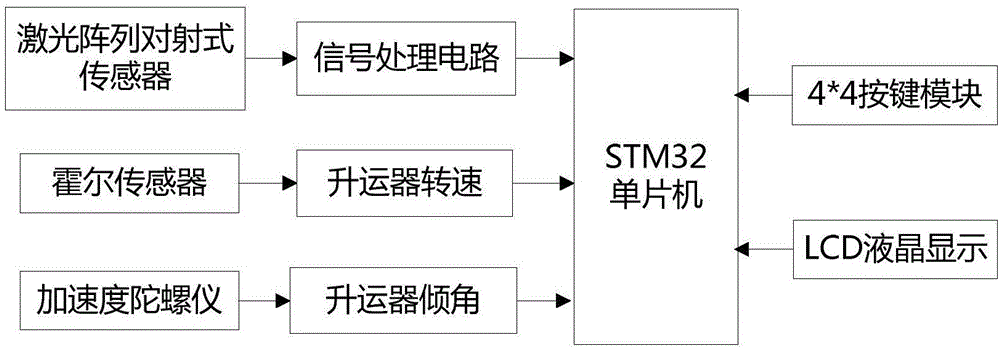

[0049] Laser array grain flow measurement device such as figure 1 , figure 2 As shown, the grain flow measurement device of the present invention includes two sets of laser beam-to-beam array sensors and elevators that emit laser light to the elevator scraper 5 in the X-Y plane. Scraper rotation speed sensor 10, elevator X-direction inclination sensor 2, Y-direction inclination sensor 4, single-chip microcomputer, key module and LCD liquid crystal display. The laser through-beam array sensor is connected to the single-chip microcomputer through a signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com