Electrothermal blowing dry box

A technology of electric blast drying and drying box, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., to achieve the effect of improving drying efficiency, improving drying effect, and solving the problem of dripping water on the top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

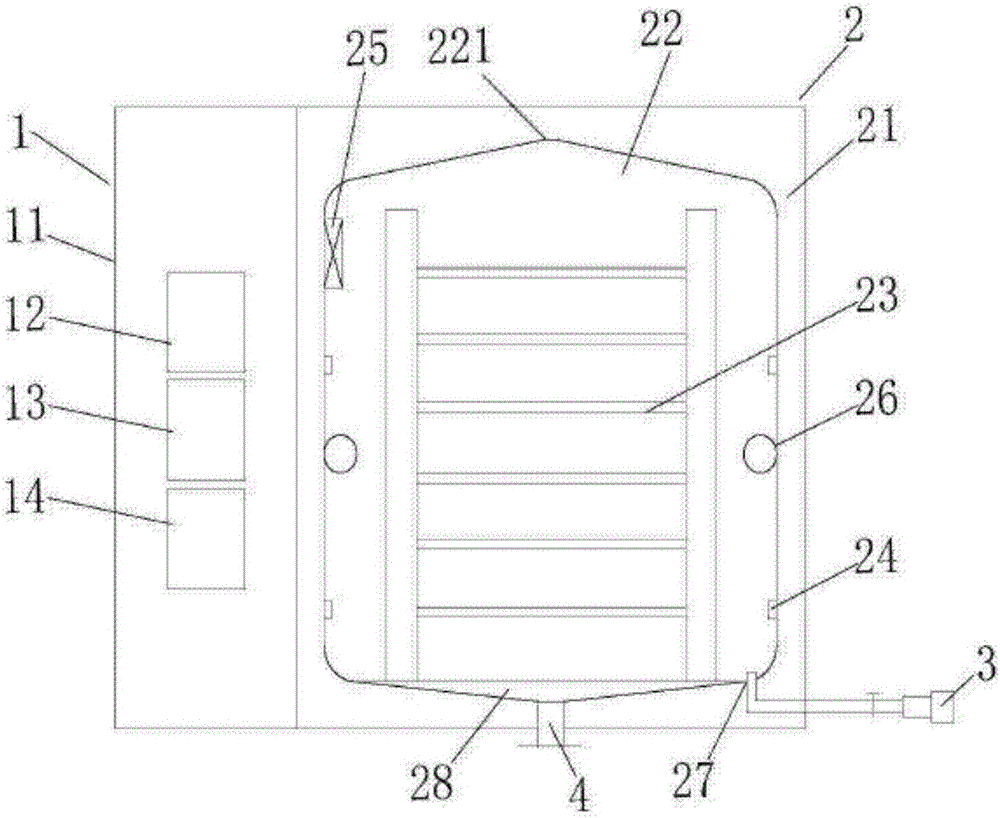

[0018] refer to figure 1 , an electric blast drying box described in this embodiment, comprising a control box 1 and a drying box 2 located on one side of the control box 1;

[0019] Described control box 1 comprises control box body 11, display 12, control panel 13 and CPU 14, and described display 12 and control panel 13 are arranged on the outer surface of control box body 11 respectively, and described CPU 14 sets Inside the control box 11;

[0020] Described drying box 2 comprises the drying box body 21 of sealing, is located at the sample shelving rack 23 in drying box body 21 inner drying chamber 22; Also be provided with temperature sensor 24 on the inner side wall of drying box body 21, in drying box body The top of the inner side wall of 21 is provided with blower fan 25, is also provided with heater 26 on the inner side wall of drying box body 21; An air extraction valve 3 is arranged in the air port 27; the top wall of the drying chamber 22 is an arched structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com