Laser perforation device and method thereof

A laser and laser technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc., can solve the problems of low reuse rate of perforating gun body, large damage of pipe string and cementing, and formation of circular holes, etc. , to achieve the effect of high reliability, high safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

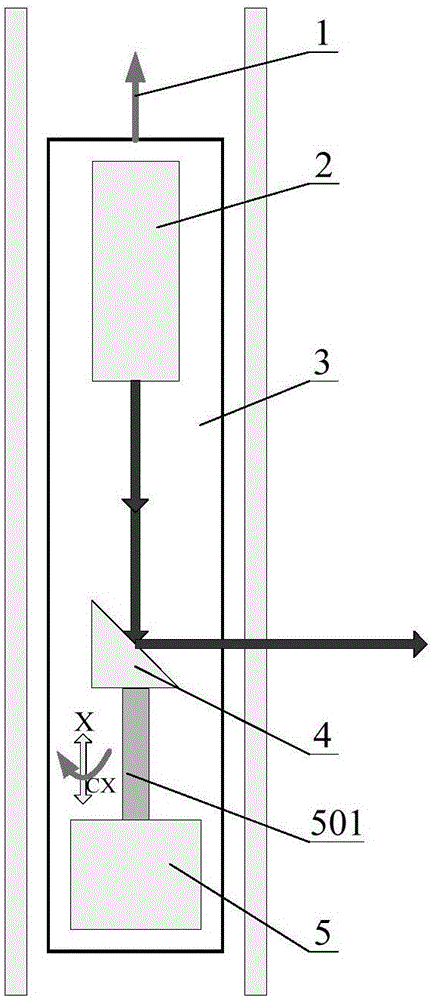

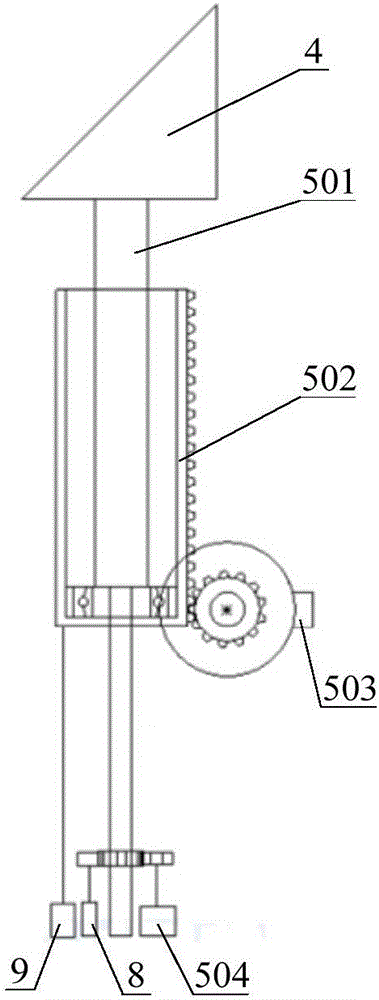

[0035] See attached figure 1 , attached figure 2 And attached image 3 , a laser perforating device of the present invention includes a ground control system, a power supply, a perforator 3, an integrating reflector 4, a motion adjustment mechanism 5, a displacement sensor 9 and an encoder 8;

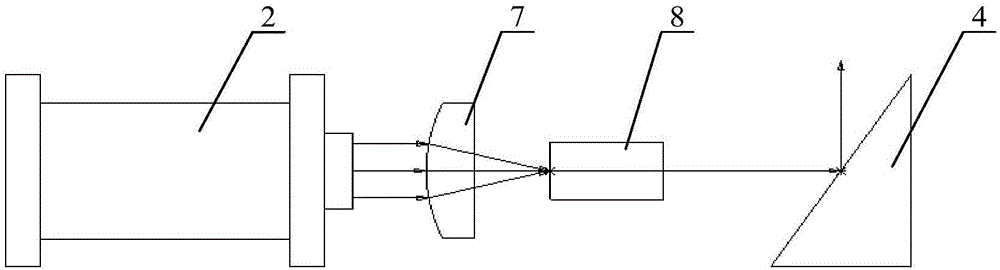

[0036] The perforator 3 includes a miniature high-power laser 2 located at the inner top of the perforator 3;

[0037] The integral reflector 4 is fixed on the upper end of the motion adjustment mechanism 5, and the integral reflector 4 is driven by the movement adjustment mechanism 5 to rotate in the circumferential direction and move in the vertical direction. 8. Collecting data, the laser light emitted by the miniature high-power laser 2 is focused through the parallel focusing optical path, emitted through the exit hole at the lower end of the perforator 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com