Mud treatment device for building pile foundation construction

A technology for construction mud and processing equipment, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc. It can solve the problems of filter sieve damage, high energy consumption, and failure to meet the needs of energy conservation and environmental protection, etc., to reduce the use of , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

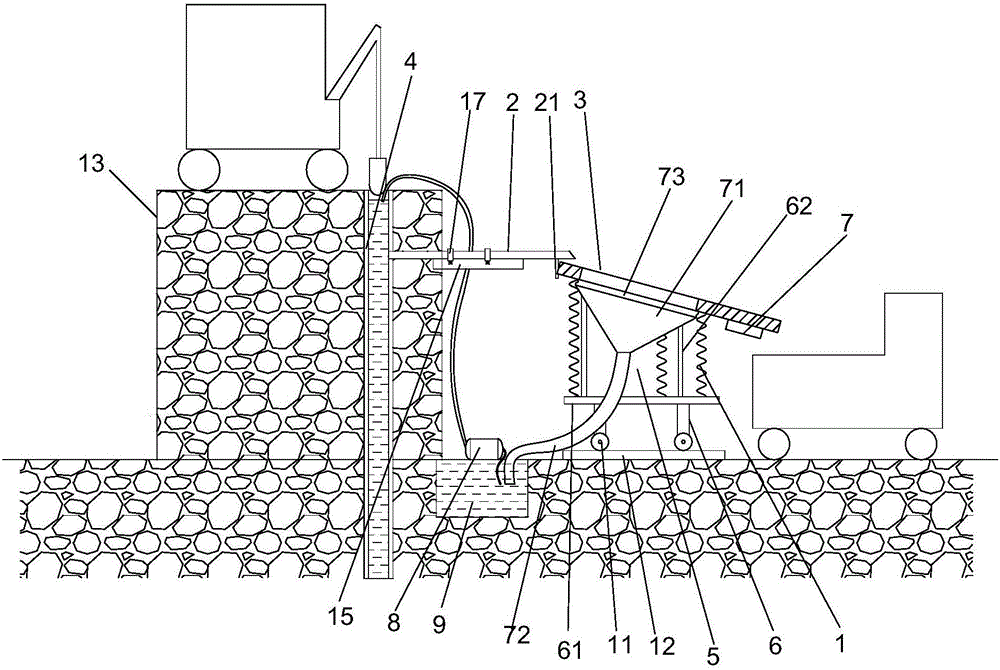

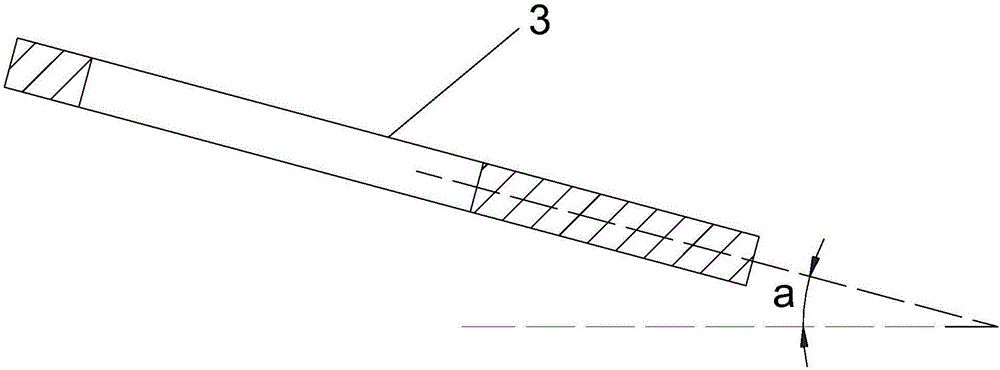

[0023] Such as figure 1 As shown, the present invention proposes a construction mud treatment device for pile foundations, comprising: clean water tank (not shown in the figure), water pump (not shown in the figure), spring 1, sand-water mixing pipeline 2, screen 3, mud Transfer device 5 , support frame 6 , vibrator 7 , mud pump 8 and mud pool 9 .

[0024] Specifically, a clean water tank is arranged beside the sand-water mixing pipeline 2, and the clean water tank is used for buffering clean water.

[0025] The input end of the water pump communicates with the clean water tank to extract clean water.

[0026] The position of the input end of the sand-water mixing pipeline 2 is higher than the position of the output end, and the overflow hole provided on the top of the casing 4 and the output end of the water pump are all connected to the input end of the sand-water mixing pipeline 2, thereby realizing the connection between the sand-water mixing pipeline 2 Internal mixing, ...

Embodiment 2

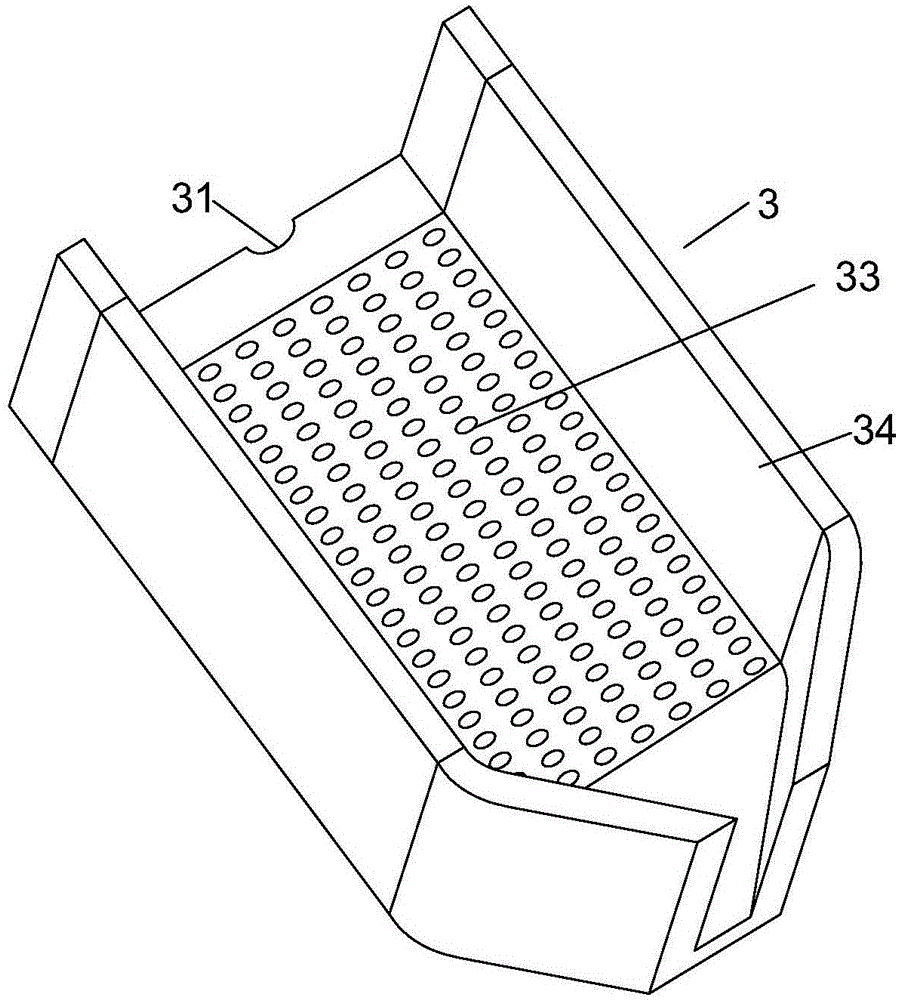

[0042] The difference between this embodiment and Embodiment 1 is that, in order to remove the residual drill dregs on the screen 3 conveniently, a movable plate 35 and a driving device 36 are arranged on the screen 3 .

[0043] Such as Figure 4 As shown, specifically, the screen 3 is provided with a movable plate 35 that can slide in the drain of the screen 3, and the screen 3 is provided with a driving device 36 for driving the movable plate 35, and when in the filtering state The movable plate 35 is located on the end face of the input end of the screen cloth 3 .

[0044] Such as Figure 4 as well as Figure 5 As shown, in order to realize the driving of the movable plate 35 by the driving device 36 . Because the drill quarrel on the screen cloth 3 can slide down automatically under the action of gravity, but there are still residual drill dregs on the screen cloth 3, long-term accumulation can cause the screen cloth 3 to be blocked, therefore the movable plate 35 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com