Template support system and construction method

A formwork support and construction method technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of unfavorable material turnover, high erection height, and long erection period, etc., and achieve the benefit of materials The effects of turnover, lower erection height, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

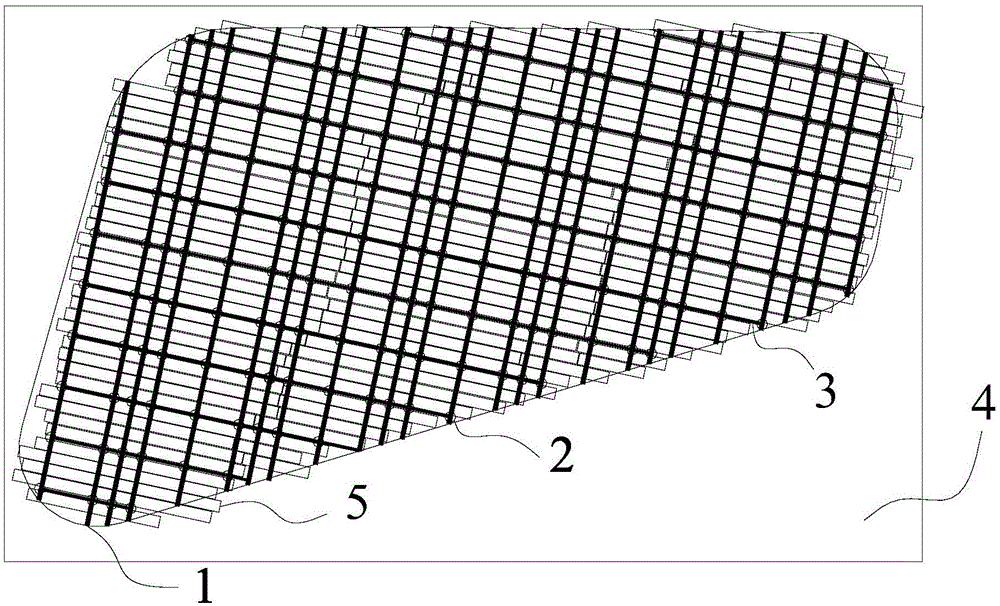

[0046] Such as figure 1As shown, a formwork support system according to the present invention includes several shaped steels 1 and formwork supports 2, and the two ends of all shaped steels 1 are respectively connected to the floor 4 where the opening area is located, and all the shaped steels 1 are I22b workers. Shaped steel, all I-beams are located on the same horizontal plane, the formwork frame 2 is connected to all the profiled steels 1, the formwork frame 2 is a full formwork frame, and the formwork frame 2 is located on all I-beams The vertical poles are equally spaced, all steel pipes 1 are provided with steel pipes 3 on the upper surface, all the steel pipes 3 have the same specification and type, the distances between each other are equal and perpendicular to the steel pipes 1, on all the steel pipes 1 Full pavement scaffolding 5, such as Figure 6 , two stay ropes 6 are added on every I-beam as reinforcing devices, and the stay ropes are steel wire ropes, and a sta...

Embodiment 2

[0049] The construction method of a kind of formwork support system of the present invention comprises using a kind of formwork support system as in embodiment 1, and its construction method comprises the following steps:

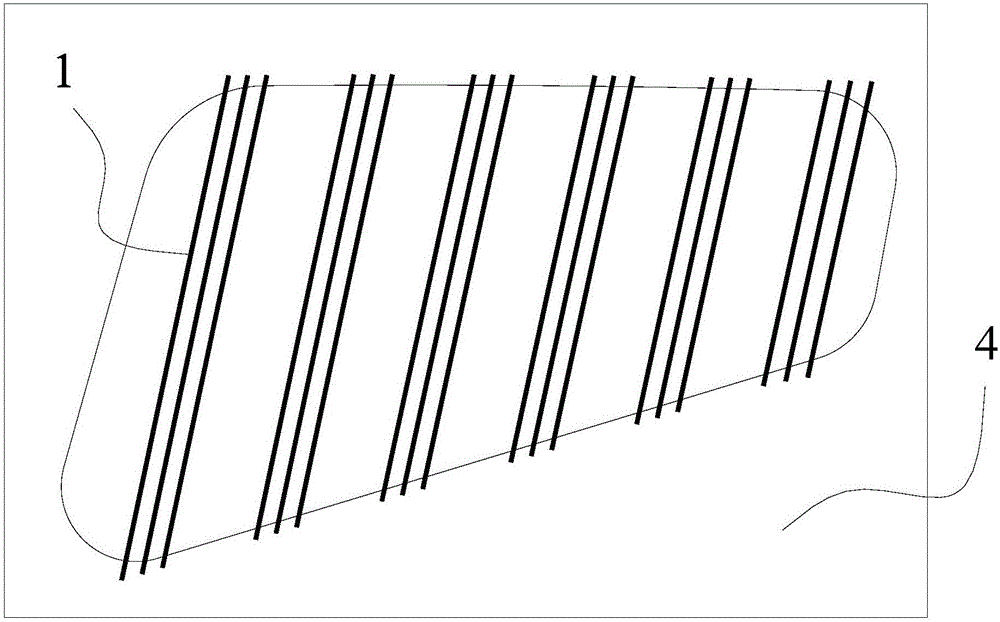

[0050] Step 1, such as figure 2 , release the center line of the beam to be poured in the opening area, and lay a section steel 1 on the center line of the beam and the positions outside the two sides of the beam;

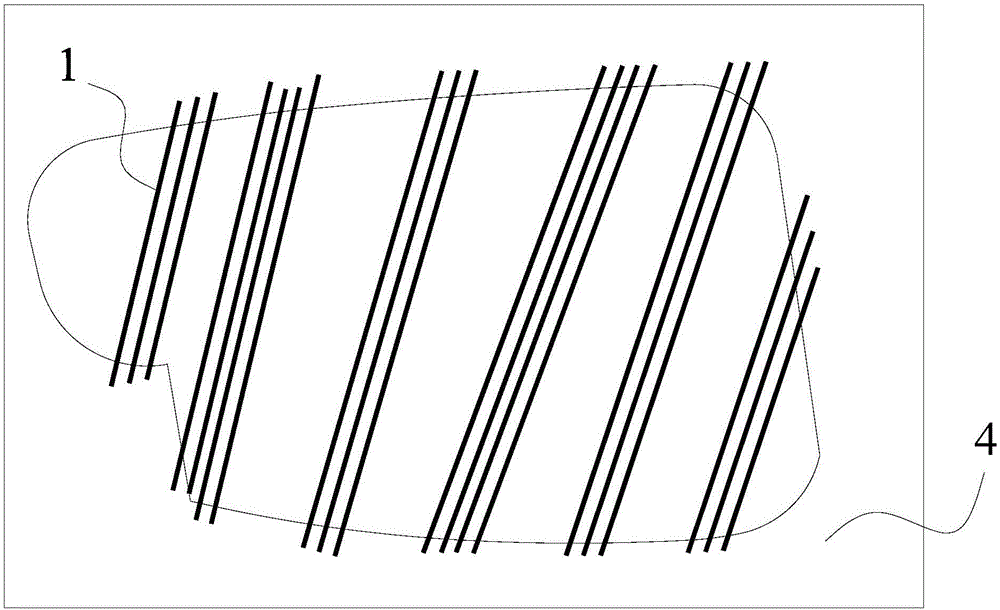

[0051] Step two, such as Figure 4 , laying section steel 1 in the opening area below the corresponding position of the slab to be poured;

[0052] Step three, such as Figure 5 , the steel pipes 3 are continuously arranged along the span direction of the shaped steel 1, all the steel pipes 3 connect all the shaped steels 1 into a whole, and a scaffold board 5 is laid on the shaped steel 1;

[0053] Step 4, such as Figure 6-7 , set the reinforcement device;

[0054] Step five, such as Figure 8 , set up the formwork frame 2, and complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com