A combined material shelf

A combined, material technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of high labor intensity, inconvenient management, occupying space resources, etc., and achieve the effect of improving safety, convenient storage, and eliminating visual blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

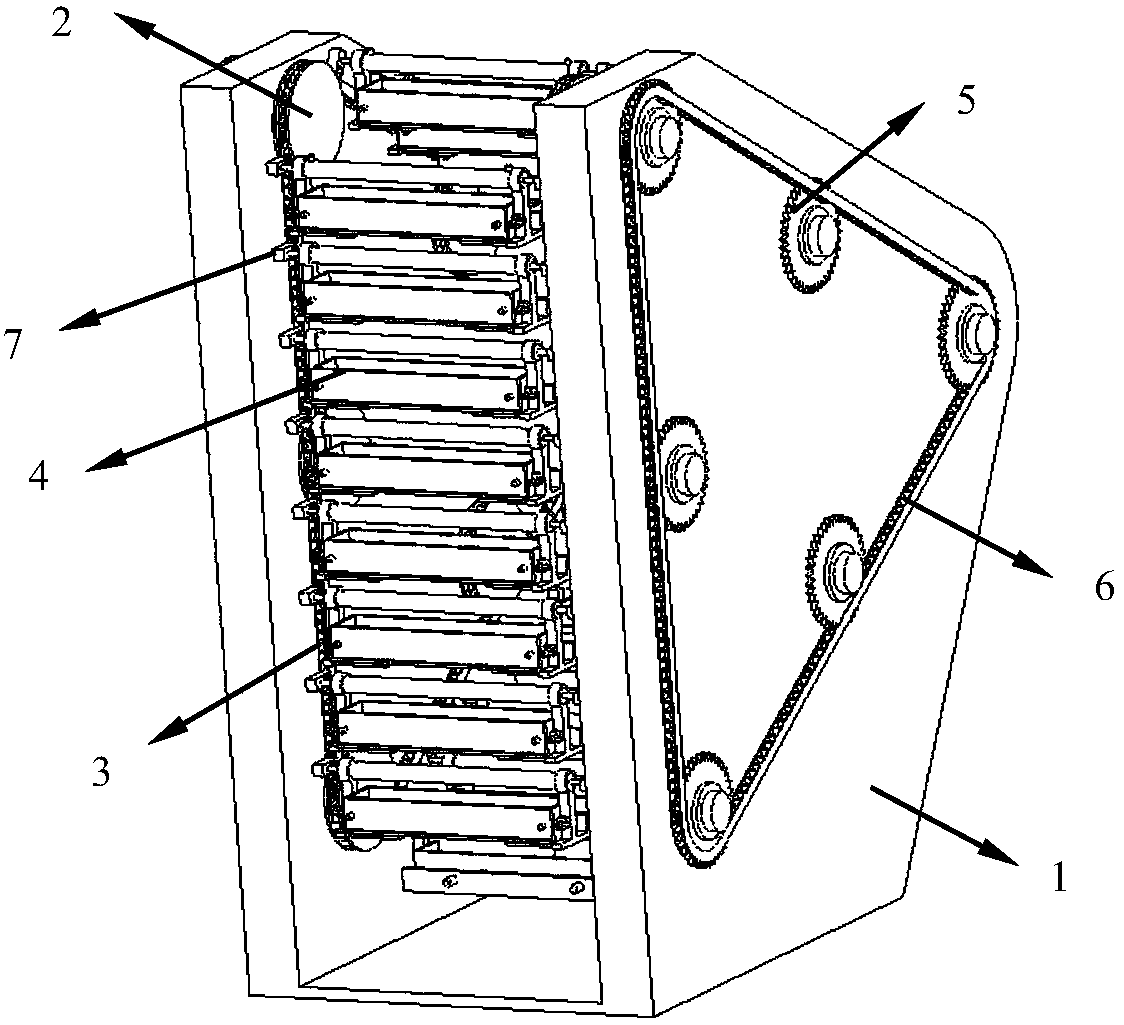

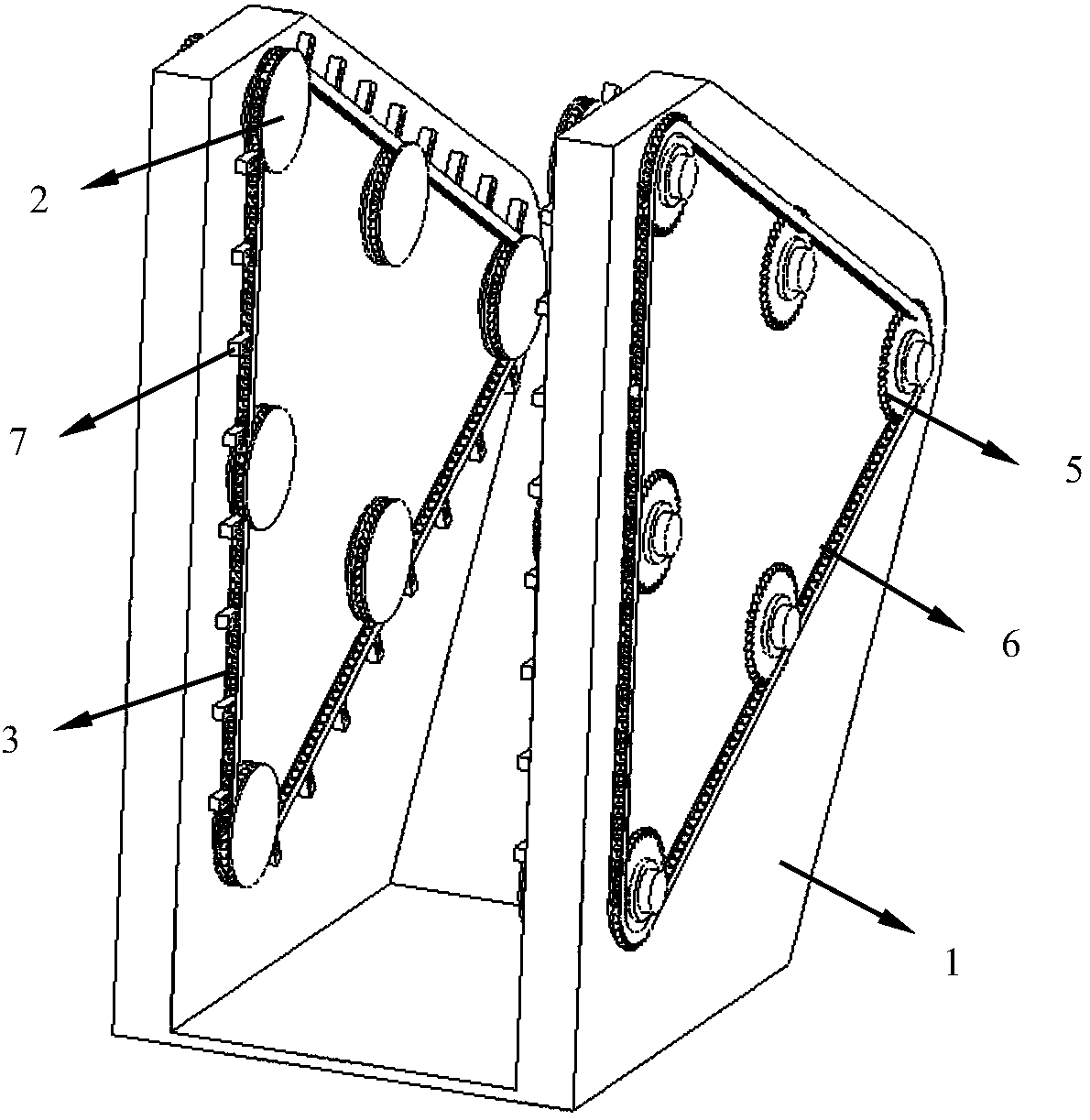

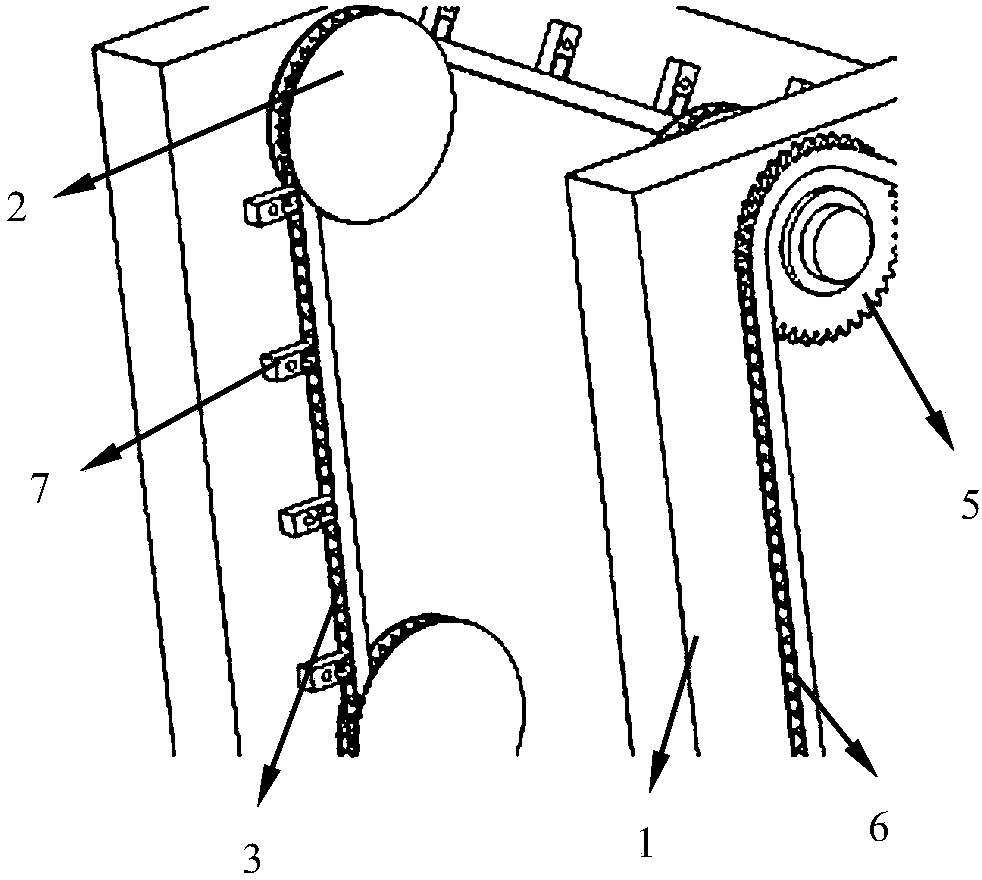

[0032] refer to figure 1 with figure 2 , the embodiment of the present invention provides a combined material shelf, including a shelf body, and the shelf body has two installation plates 1 arranged at a predetermined distance apart. In order to ensure the stability of placement, the two installation plates 1 They can be connected through connecting plates. The inner surfaces of the two mounting plates 1 are provided with a plurality of first sprockets 2, the inner surfaces refer to the opposite surfaces of the two mounting plates 1, wherein the same mounting plate 1 A plurality of the first sprockets 2 are connected through the transmission of the first chain 3, and a plurality of sets of material storage parts 4 are arranged between the two mounting plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com