Method for detecting state of gap of DC switch

A state detection and turnout technology, which is applied in the locking mechanism for turnout, railway car body parts, railway signal and safety, etc., can solve the problems of increasing cost and technical difficulty, high bandwidth of image transmission, and easy safety risks , to achieve the effect of difficult installation and construction, reduced difficulty of operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

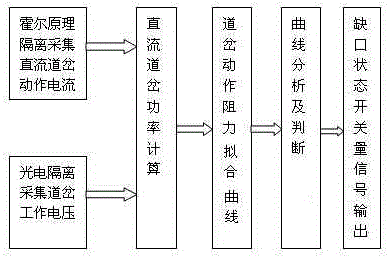

[0023] like figure 1 As shown, the present invention includes a method for detecting the gap state of a DC turnout, comprising the following steps:

[0024] Step A) isolating and collecting the real-time operating current I of the DC switch, and collecting the real-time operating voltage U of the switch;

[0025] Step B) Calculate the real-time DC switch power P=U×I according to the real-time operating current I measured in step A) and the real-time operating voltage U;

[0026] Step C) According to the real-time DC turnout power P calculated in step B) and the speed V of the switch machine, calculate the action resistance of the turnout F=P÷V, thereby drawing the fitting curve of the action resistance of the turnout; wherein the speed of the switch machine V can know when the switch machine is working.

[0027] Step D) Analyzing the fitting curve of the switch action resistance obtained in step C), and judging whether the resistance fitting curve is the normal action state ...

Embodiment 2

[0033]The present embodiment is preferably as follows on the basis of embodiment 1: due to the continuous and linear readings, simple method, long service life, and the ability to measure the magnetic field of small spaces and small gaps when using the Hall effect to measure the magnetic field, it is very suitable for use It is used to collect the operating current of the DC turnout; the operating voltage of the turnout is collected by means of photoelectric isolation, which can isolate the interference source from the easy-interference source, avoid the influence of the easy-interference source on the voltage to be measured, and ensure the accuracy of the final measurement result. Therefore, in step A ) The real-time operating current I of the DC turnout adopts the isolation and collection of the Hall principle, and the real-time working voltage U of the turnout adopts the photoelectric isolation collection, which is simple in engineering construction and safe in monitoring.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com