PVC (polyvinyl chloride) negative ion antibacterial glove and manufacturing process thereof

A negative ion antibacterial and production process technology, applied in gloves, clothing, clothing, etc., can solve the problems of not endowing PVC gloves with anti-bacterial and sterilizing capabilities, and cannot protect the health of users and patients, so as to protect the health of users and patients , shorten the dipping time, increase the effect of dipping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

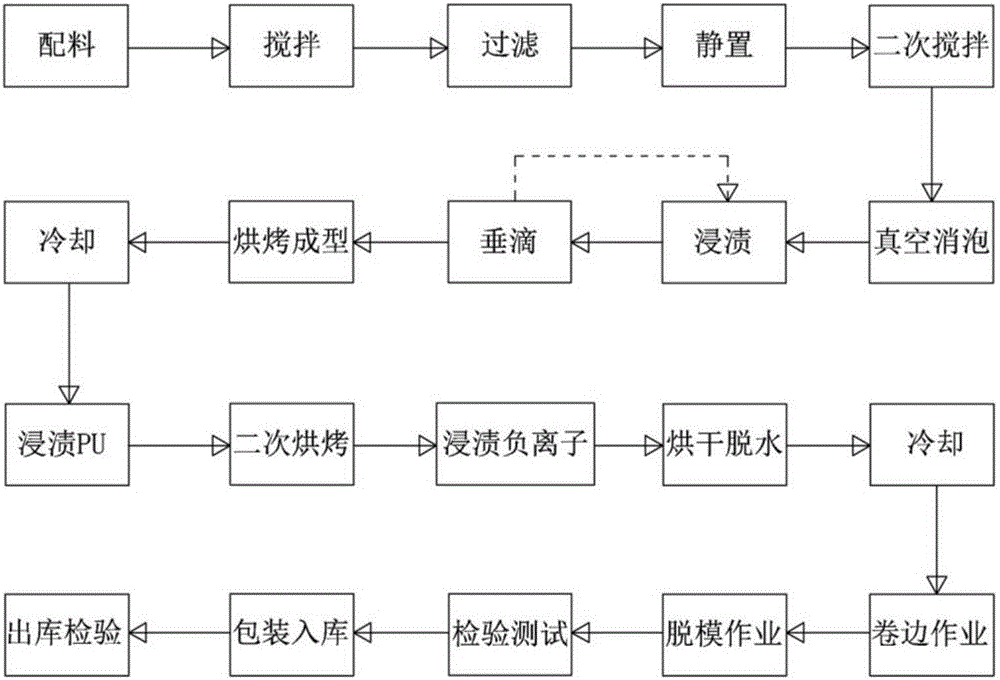

[0054] Such as figure 1 Shown, the production technology of PVC negative ion antibacterial gloves comprises the following steps,

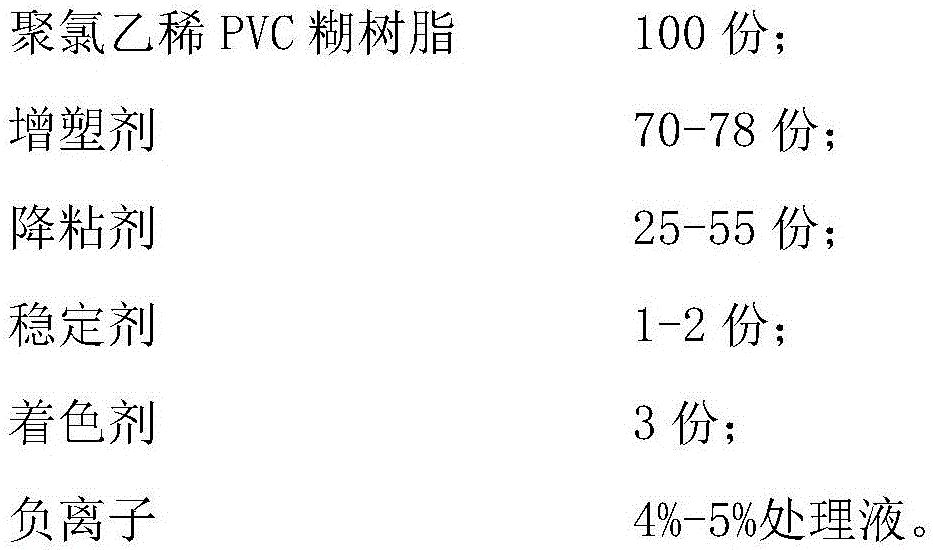

[0055] Step 1, batching, the raw materials are mixed according to the ratio of 100 parts of polyvinyl chloride PVC paste resin: 72 parts of plasticizer: 26 parts of viscosity reducer: 1 part of stabilizer: 3 parts of coloring agent;

[0056]Step 2, stirring, stirring the mixed ingredients at a high speed, controlling the stirring speed in the range of 1500 rpm during mixing, mixing for 1 hour, and controlling the mixing temperature at 65°C;

[0057] Step 3, filtering, filtering the stirred ingredients into the storage tank with a 250-mesh stainless steel filter;

[0058] Step 4, stand still, let the ingredients in the storage tank stand for 48 hours;

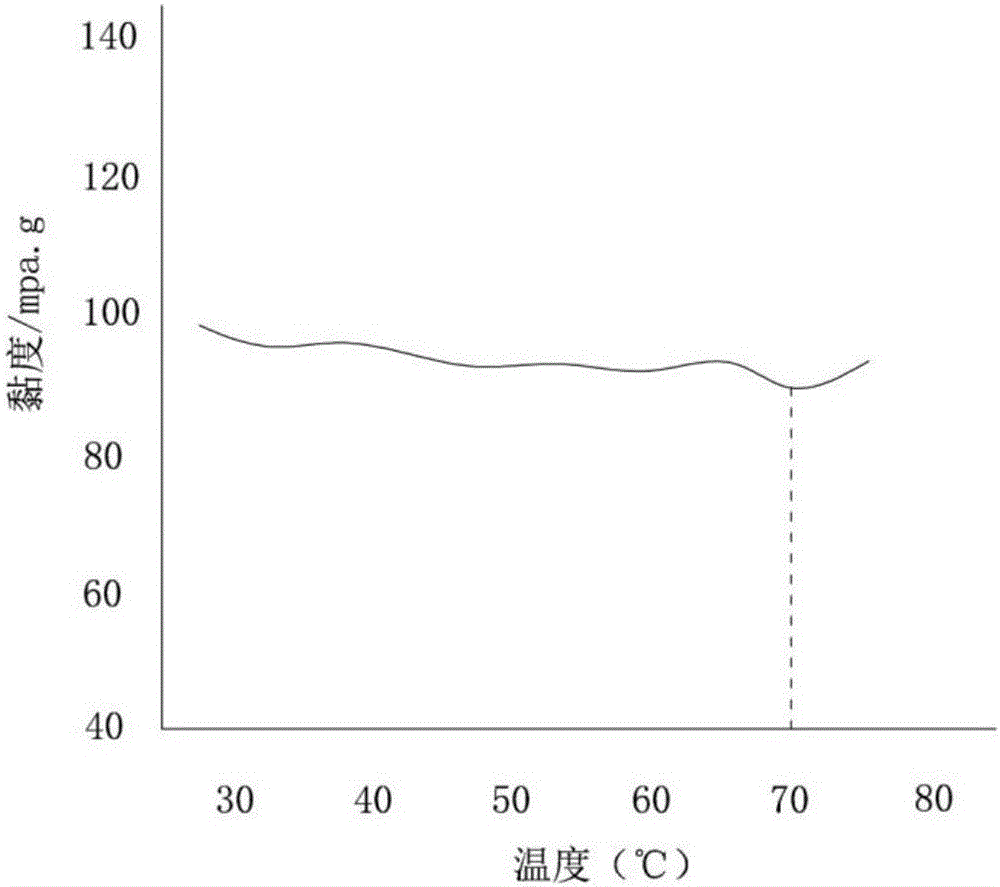

[0059] Step 5, secondary stirring, high-speed stirring of the ingredients after standing still, control the stirring speed in the range of 1500 rpm when mixing, mix for 1 hour, and control the mixi...

Embodiment 2

[0076] Such as figure 1 Shown, the production technology of PVC negative ion antibacterial gloves comprises the following steps,

[0077] Step 1, batching, the raw materials are mixed according to the ratio of 100 parts of polyvinyl chloride PVC paste resin: 72 parts of plasticizer: 26 parts of viscosity reducer: 1 part of stabilizer: 3 parts of coloring agent;

[0078] Step 2, stirring, stirring the mixed ingredients at a high speed, controlling the stirring speed in the range of 1500 rpm during mixing, mixing for 1 hour, and controlling the mixing temperature to 70°C;

[0079] Step 3, filtering, filtering the stirred ingredients into the storage tank with a 250-mesh stainless steel filter;

[0080] Step 4, stand still, let the ingredients in the storage tank stand for 48 hours;

[0081] Step 5, secondary stirring, high-speed stirring of the ingredients after standing still, control the stirring speed in the range of 1500 rpm when mixing, mix for 1 hour, and control the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com