Automatic fish washing machine

A fish washing machine, automatic technology, applied in the direction of processing fish, fish cleaning/descaling, slaughtering, etc., can solve the problems of high labor intensity, troublesome removal, incomplete removal, etc., and achieves simple structure principle, good stability and effect. ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

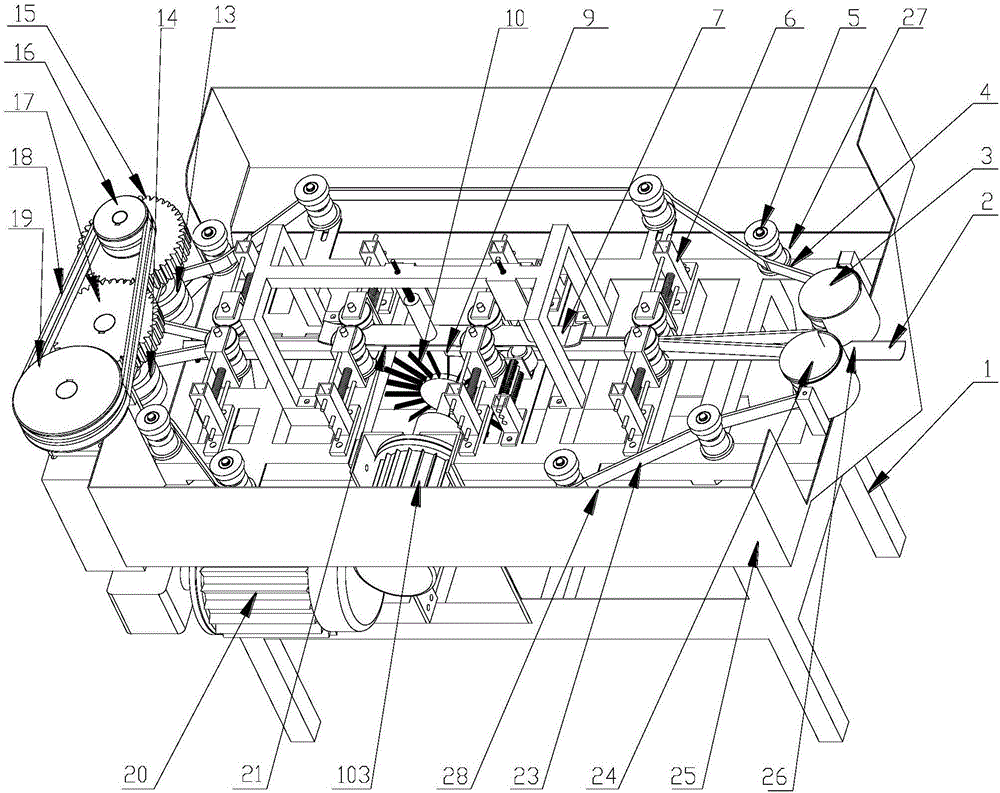

[0029] Such as figure 1 The automatic fish washing machine shown includes a frame 1, and also includes a first fish belt group 27, a second fish belt group 28, a fish pressing mechanism 7, a fish belly stretching device 9, a visceral and black film cleaning device 10 and fish body chute 2, the first fish belt group 27 and the second fish belt group 28 consistent with the transmission direction are installed side by side on the frame 1, the first fish belt group 27 and the second fish belt group 28 A delivery channel 21 is formed between them; the fish body chute 2 is affixed to the lower side of the delivery channel 21 and extends to the outside of the starting end of the delivery channel 21 to form a fish inlet 26; the fish pressing mechanism 7 is affixed to the delivery channel 21; the fish belly stretching device 9 is affixed to the fish body chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com