Method for roof greening by utilizing maintain rice

A roof greening and mountain rice technology, applied in the greening field, can solve problems such as increasing the urban greening rate, and achieve the effect of ensuring healthy growth and reducing roof load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

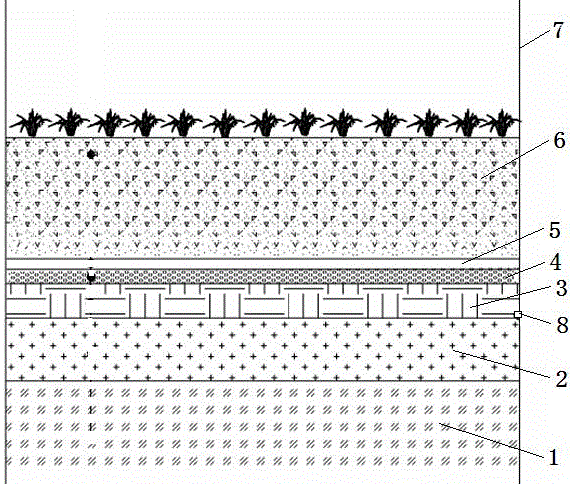

[0040] see figure 1 In the present embodiment, the method for using mountain rice to carry out roof greening includes the following steps.

[0041] (1) Lay a layer of cement mortar layer 2 for waterproof and leakproof on the top floor 1.

[0042] (2) Use the guardrail 7 to frame the planting range, the bottom of the guardrail 7 is sealed with cement mortar, and the lower part of the guardrail 7 is provided with drainage holes 8 . The height of guardrail 7 is 40cm, and this guardrail 7 bottoms are sealed with cement mortar in the 10cm high scope of this guardrail 7, and drainage hole 8 is located at distance guardrail 7 bottom 10cm places.

[0043] (3) Lay a broken brick layer 3 for water storage on the cement mortar layer 2 within the range framed by the guardrail 7 .

[0044] (4) Lay a layer of ceramsite layer 4 for filling the surface gap of the broken brick layer 3 on the leveled broken brick layer 3, and then lay a layer of non-woven fabric layer 5 on the ceramsite layer 4...

Embodiment 2

[0051] see figure 1 In the present embodiment, the method for using mountain rice to carry out roof greening includes the following steps.

[0052] (1) Lay a layer of cement mortar layer 2 for waterproof and leakproof on the top floor 1.

[0053] (2) Use the guardrail 7 to frame the planting range, the bottom of the guardrail 7 is sealed with cement mortar, and the lower part of the guardrail 7 is provided with drainage holes 8 . The height of guardrail 7 is 40cm, and this guardrail 7 bottoms are sealed with cement mortar in the 10cm high scope of this guardrail 7, and drainage hole 8 is located at distance guardrail 7 bottom 10cm places. The thickness of the cement mortar layer 2 is 10cm.

[0054] (3) Lay a broken brick layer 3 for water storage on the cement mortar layer 2 within the range framed by the guardrail 7 .

[0055] (4) Lay a layer of ceramsite layer 4 for filling the surface gap of the broken brick layer 3 on the leveled broken brick layer 3, and then lay a lay...

Embodiment 3

[0066] see figure 1 In the present embodiment, the method for using mountain rice to carry out roof greening includes the following steps.

[0067] (1) Lay a layer of cement mortar layer 2 for waterproof and leakproof on the top floor 1.

[0068] (2) Use the guardrail 7 to frame the planting range, the bottom of the guardrail 7 is sealed with cement mortar, and the lower part of the guardrail 7 is provided with drainage holes 8 . The height of guardrail 7 is 40cm, and this guardrail 7 bottoms are sealed with cement mortar in the 10cm high scope of this guardrail 7, and drainage hole 8 is located at distance guardrail 7 bottom 10cm places.

[0069] (3) Lay a broken brick layer 3 for water storage on the cement mortar layer 2 within the range framed by the guardrail 7 .

[0070] (4) Lay a layer of ceramsite layer 4 for filling the surface gap of the broken brick layer 3 on the leveled broken brick layer 3, and then lay a layer of non-woven fabric layer 5 on the ceramsite layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com