A premixed graded strong swirl low pollution liquefied gas burner

A burner, low-polluting technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of increasing the premixed air opening angle, increasing the combustion range, and high pollutant emissions, and achieves the reduction of emissions, Reduce flame temperature and enhance the effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

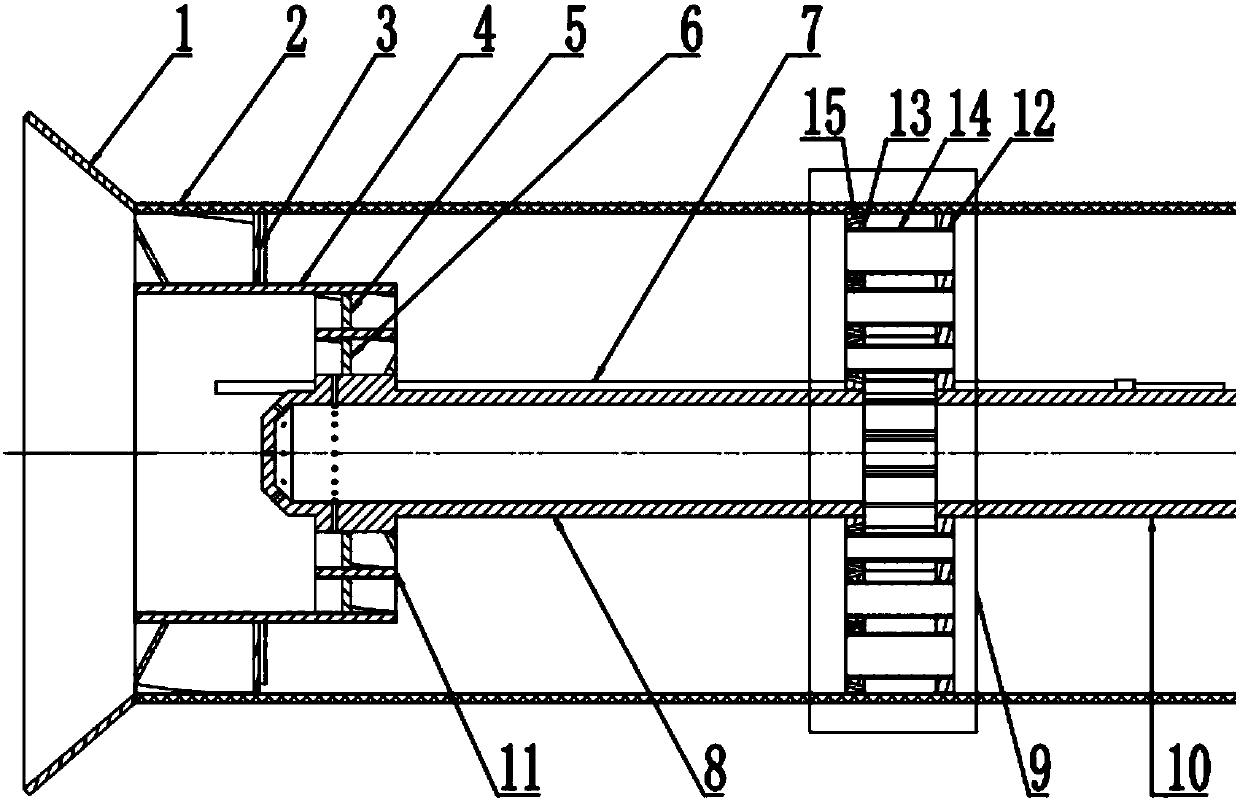

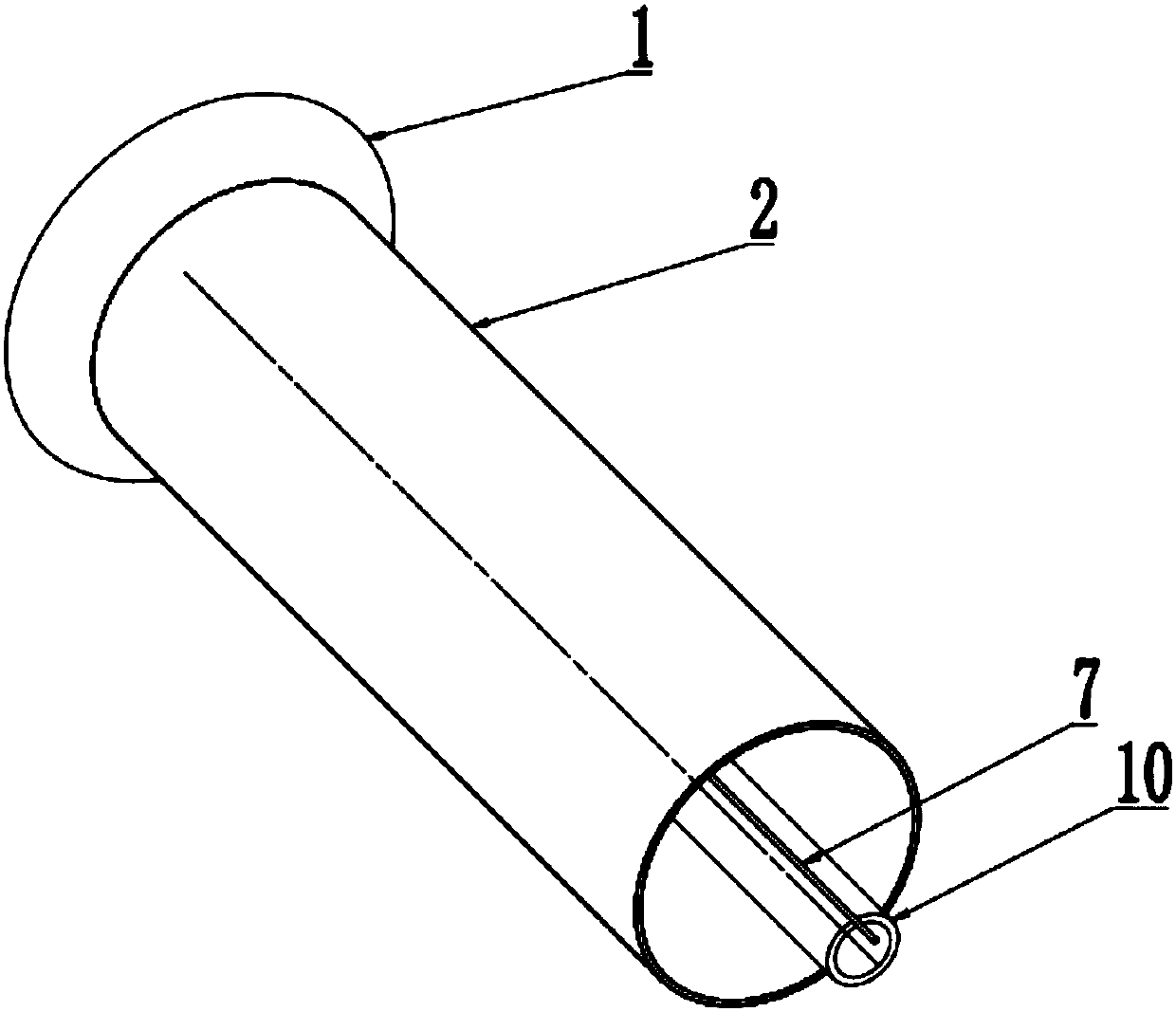

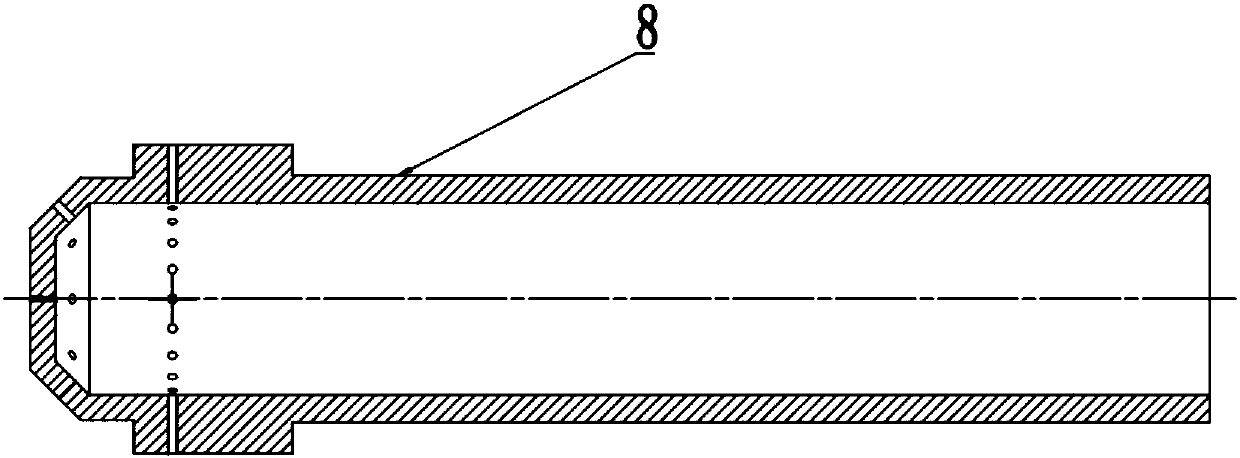

[0028] Such as figure 1 As shown in this embodiment, a premixed strong swirling flame diffusion burner adopts the structural design of porous mixing plate premixing and center classification, and the whole is made of stainless steel, and the burner part includes: pre-combustion nozzle , including pre-combustion level shell 4, pre-combustion level outer swirl blade 5, pre-combustion level inner swirl blade 6, pre-combustion level pipeline 8; main combustion level nozzle, including main combustion level swirl blade 3; porous mixing Mixing plate 9, gas pipeline 10 for fuel supply and air pipeline 2 for air supply; the air pipeline is welded and connected to the combustion chamber casing 1 by welding. The air pipeline and the casing inlet of the combustion chamber can be connected by welding, which is used to guide the air to pass through the swirl burner and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com