Method and system for rapid switching of hot-dip galvanized coating thickness based on dynamic compensation of tool distance

A coating thickness and dynamic compensation technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of large quality fluctuation, long time for specification switching, slow adjustment of air knife pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better illustrate the present invention, the present invention will be described in detail with a preferred embodiment and with accompanying drawings, specifically as follows:

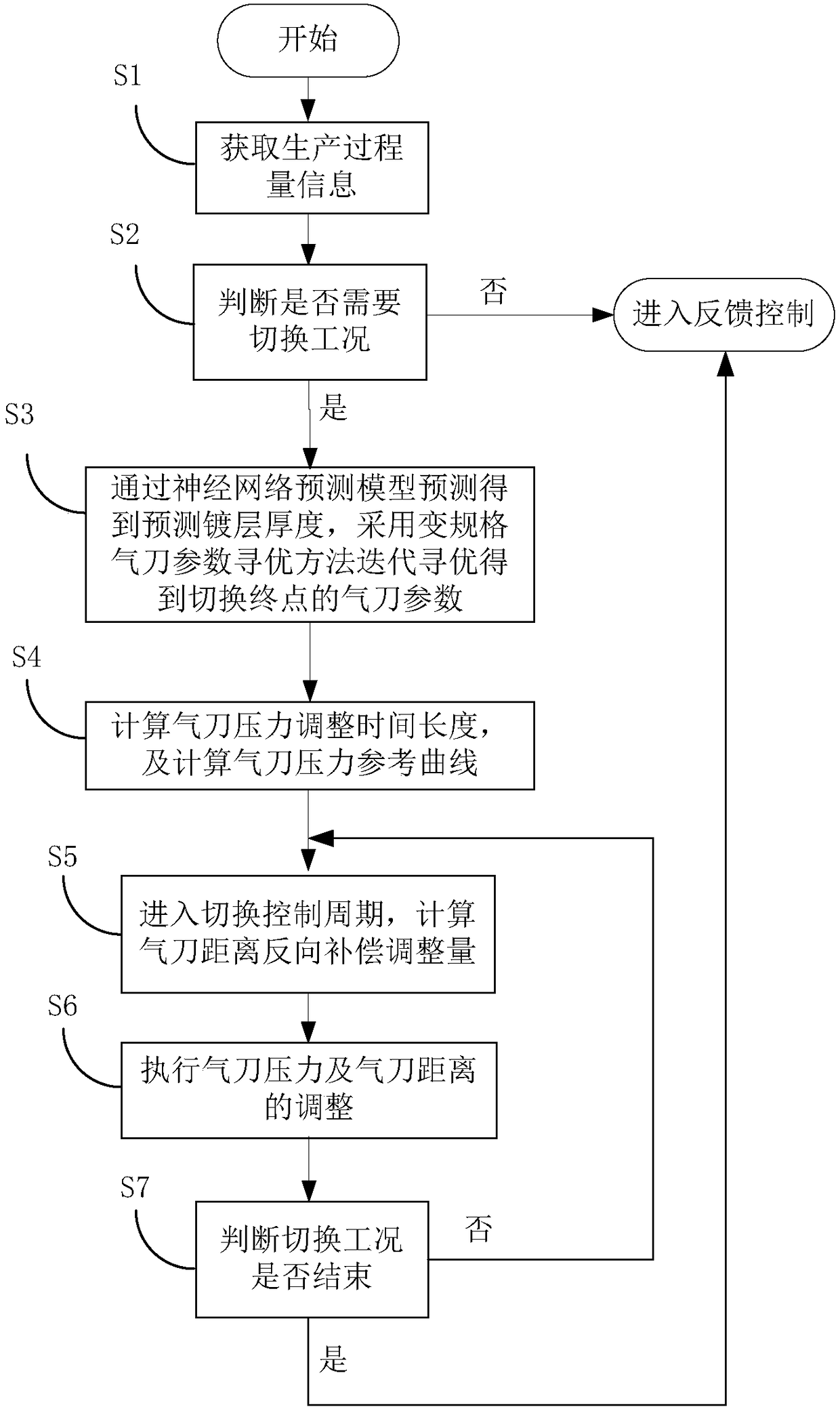

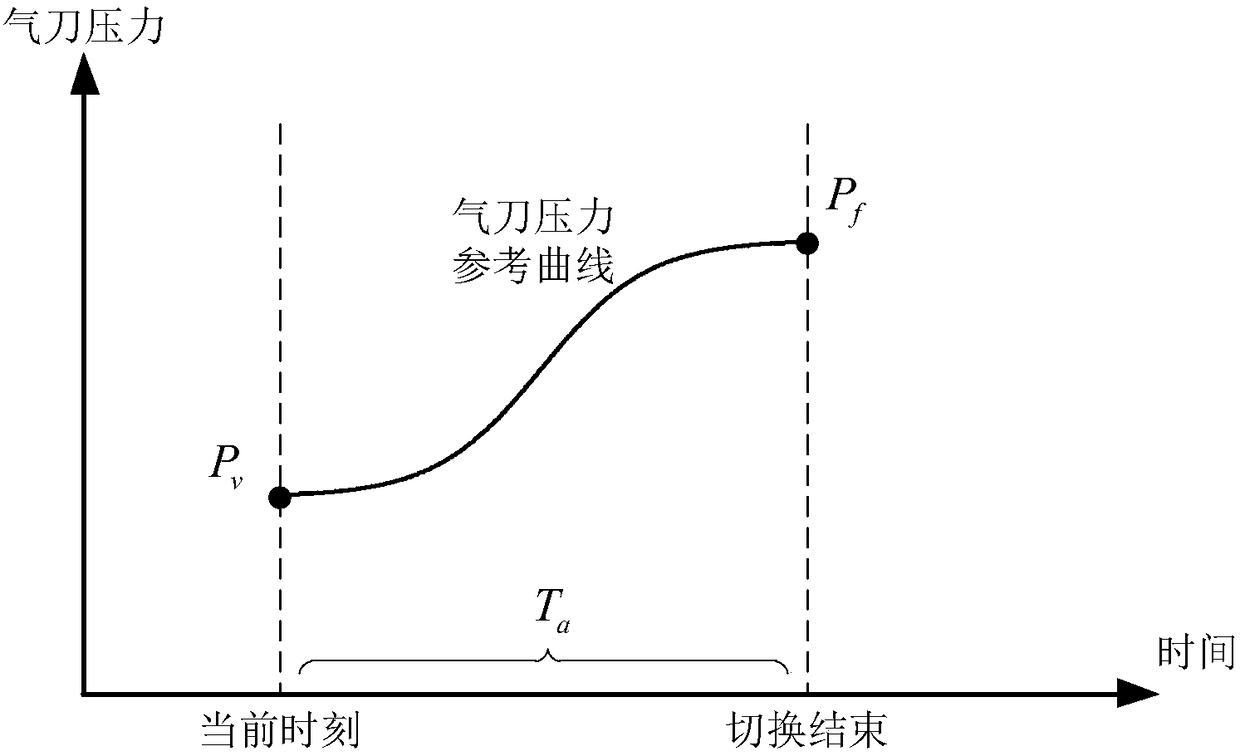

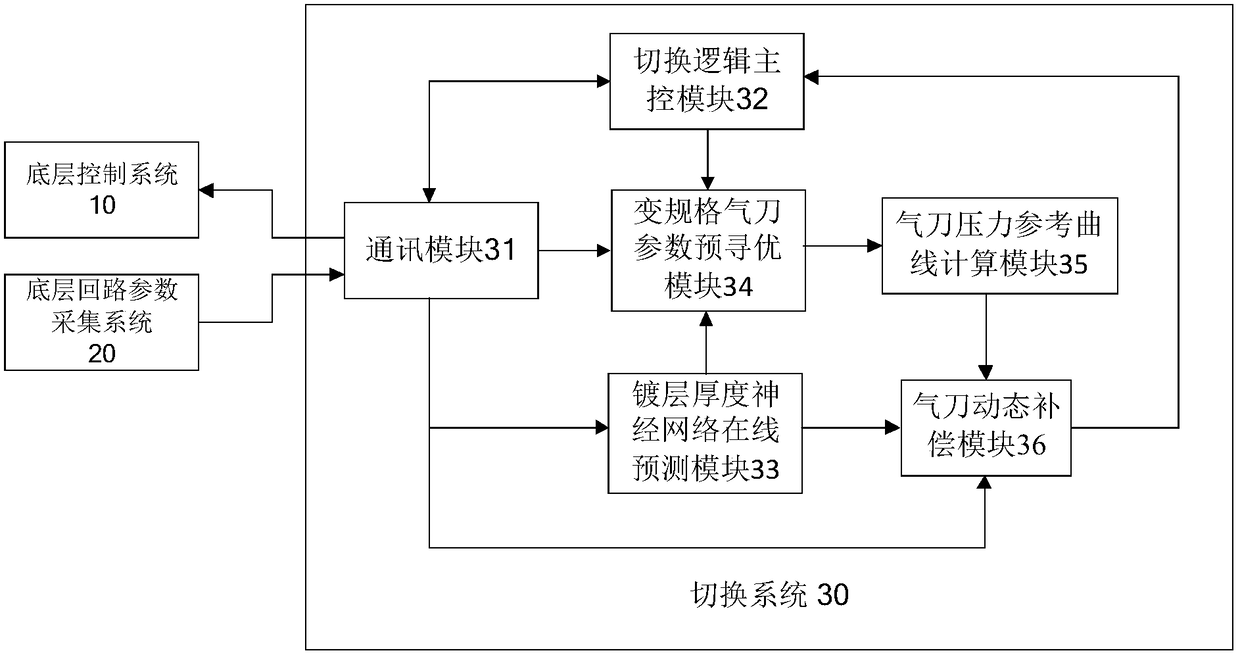

[0046] Such as figure 1 As shown, the overall flow of a method for rapid switching of hot-dip galvanized coating thickness based on dynamic compensation of tool distance provided in this embodiment includes the following steps:

[0047] S1: Obtain real-time production process quantity information;

[0048] S2: Judging whether it is necessary to switch working conditions according to the production process quantity information, if not, enter the feedback control, if yes, enter step S3;

[0049] S3: Predict the coating thickness according to the current working condition data through the neural network prediction model, and then iterate the air knife distance and air knife pressure based on the predicted coating thickness and the production process quantity information by using the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com