Hydrofracturing sectional blasting fast tunnel excavation method

A segmental blasting and hydraulic fracturing technology, which is applied in blasting, tunneling, earthwork drilling and mining, etc., can solve the problems of low efficiency and slow tunneling speed in underground mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below.

[0016] The implementation of the above-mentioned hydraulic fracturing method for excavating a roadway by segmental blasting provided by the present invention specifically includes the following steps.

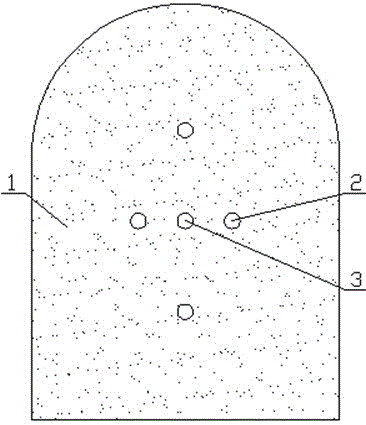

[0017] 1. Use water exploration to drill 5 boreholes on the advanced excavation surface, and the direction of the boreholes is parallel to the excavation surface; the arrangement of the four outer boreholes presents a prismatic arrangement, and the last hole is arranged in the middle of the prism. The depth of the borehole is generally about 40m. On the one hand, the borehole can detect the water situation in advance, and on the other hand, it can carry out follow-up work.

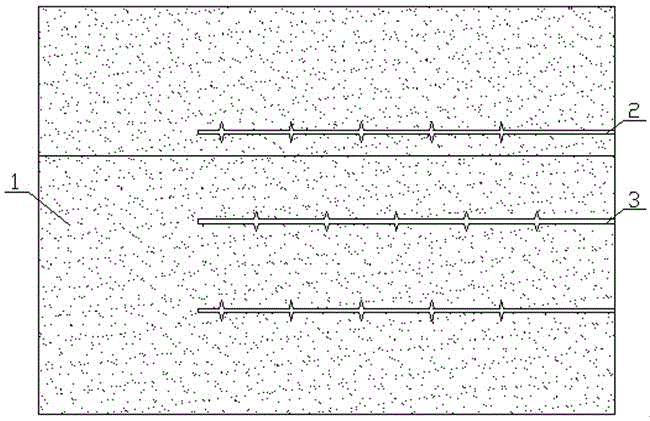

[0018] 2. In all boreholes, use a slotted drill to open several wedge-shaped ring grooves from the bottom of the hole to the hole in turn, and each wedge-shaped ring groove is separated by 5-9m. Slotted d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com