Water-resistant ardealite mould box and preparation method thereof

A phosphogypsum and molding technology, which is applied in the field of water-resistant phosphogypsum molding and its preparation, can solve the problems of high damage rate, water resistance, and low strength, and achieve the effects of increased strength, reduced overall cost, and enhanced compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

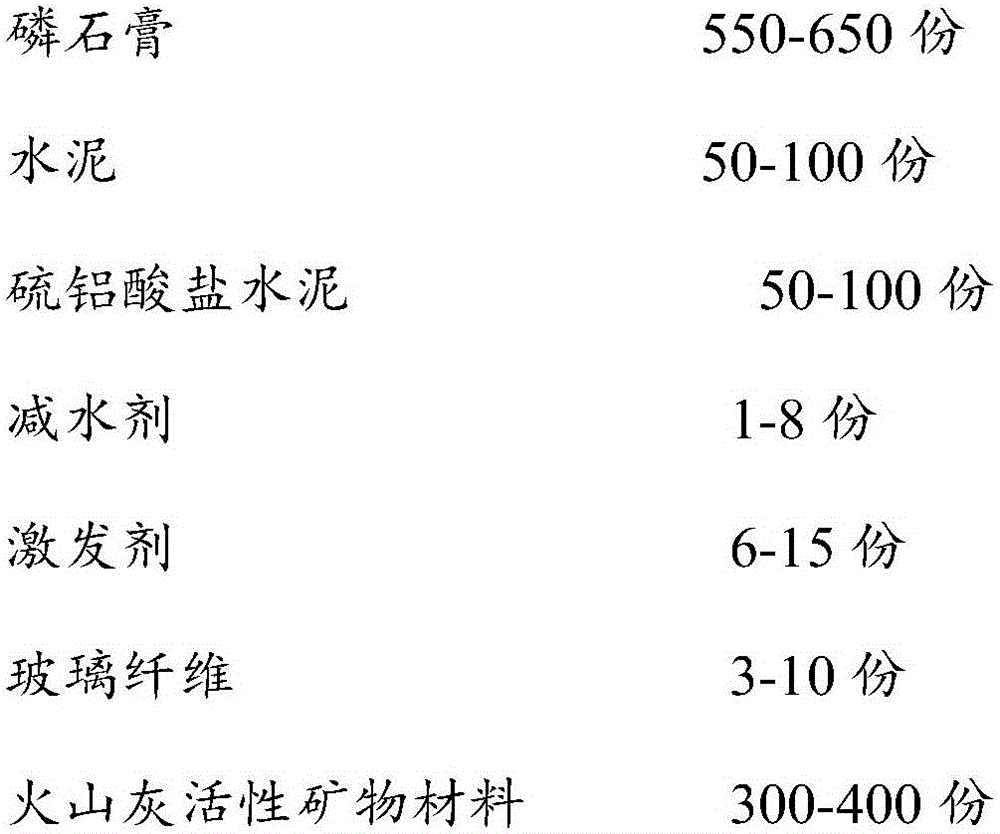

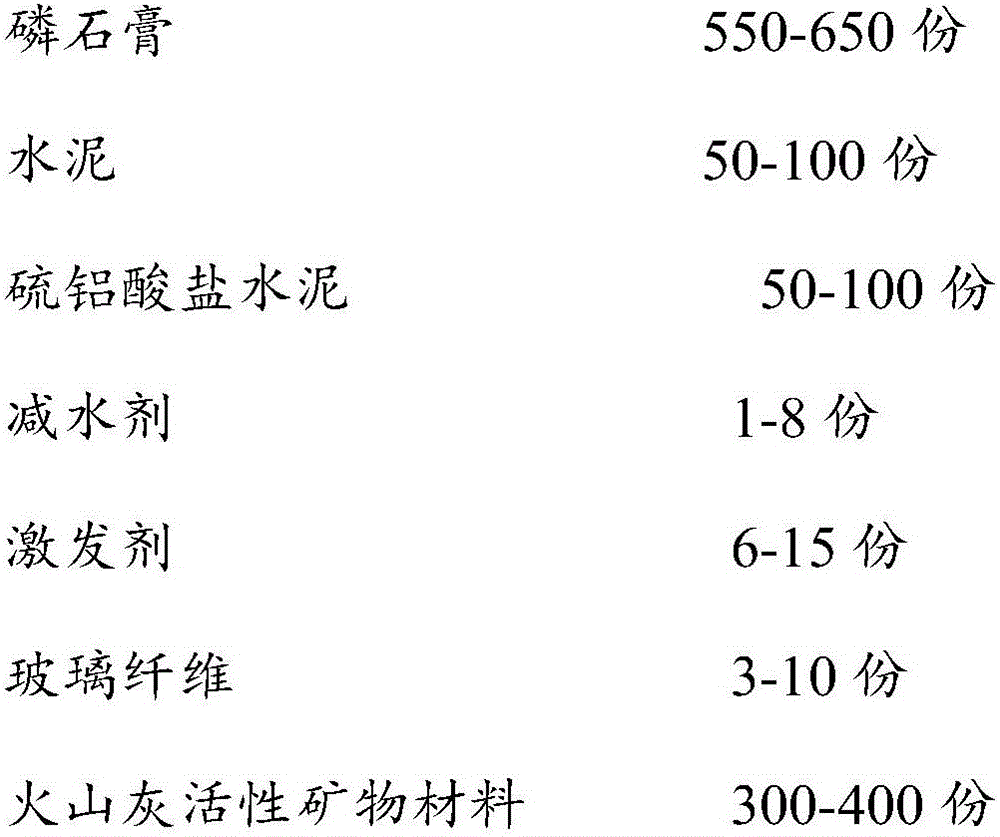

Method used

Image

Examples

Embodiment 1

[0024] Take 564 parts of phosphogypsum, 50 parts of sulphoaluminate cement, 50 parts of 42.5 cement, 320 parts of slag S95, 3 parts of polycarboxylate superplasticizer, 8 parts of alum, and 5 parts of glass fiber, and mix and stir the above weight components for 3 -5min, prepare an appropriate amount of water, pour the mixed components into the water and stir for 30 seconds, pour them into the mold to form, rest for 10 minutes, then release the mold, then cover it with a plastic film and maintain it for 3 days, the moldability of the obtained water-resistant phosphogypsum is : Initial setting 3min, 3-day dry flexural strength: 3.5MPa, 3-day dry compressive strength: 12MPa, 3-day softening coefficient: 0.88.

Embodiment 2

[0026] Take 585 parts of phosphogypsum, 60 parts of sulphoaluminate cement, 60 parts of 42.5 cement, 200 parts of slag S95, 1 part of polycarboxylate superplasticizer, 10 parts of alum, and 4 parts of glass fiber, and mix and stir the above weight components for 3 -5min, prepare an appropriate amount of water, pour the mixed components into the water and stir for 30 seconds, pour them into the mold to form, rest for 10 minutes, then release the mold, then cover it with a plastic film and maintain it for 3 days, the moldability of the obtained water-resistant phosphogypsum is : Initial setting 4min, 3-day dry flexural strength: 3.3MPa, 3-day dry compressive strength: 11.8MPa, 3-day softening coefficient: 0.78.

Embodiment 3

[0028] Take 634 parts of phosphogypsum, 50 parts of sulfoaluminate cement, 70 parts of 42.5 cement, 230 parts of slag S95, 3 parts of polycarboxylate superplasticizer, 10 parts of alum, and 3 parts of glass fiber, and mix and stir the above weight components for 3 -5min, prepare an appropriate amount of water, pour the mixed components into the water and stir for 30 seconds, pour them into the mold to form, rest for 10 minutes, then release the mold, then cover it with a plastic film and maintain it for 3 days, the moldability of the obtained water-resistant phosphogypsum is : Initial setting 4min, 3-day dry flexural strength: 3.7MPa, 3-day dry compressive strength: 13.6MPa, 3-day softening coefficient: 0.85.

[0029] The invention adopts the waste residue phosphogypsum directly discharged by phosphorus chemical enterprises as the main cementitious material, conforms to the active mineral material of volcanic ash, and adds some activators, and through chemical reaction, changes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com