Pneumatic logistics workstation

A workstation, logistics technology, applied in the direction of transportation and packaging, conveyors, etc., can solve problems such as need, no buffering or automatic conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

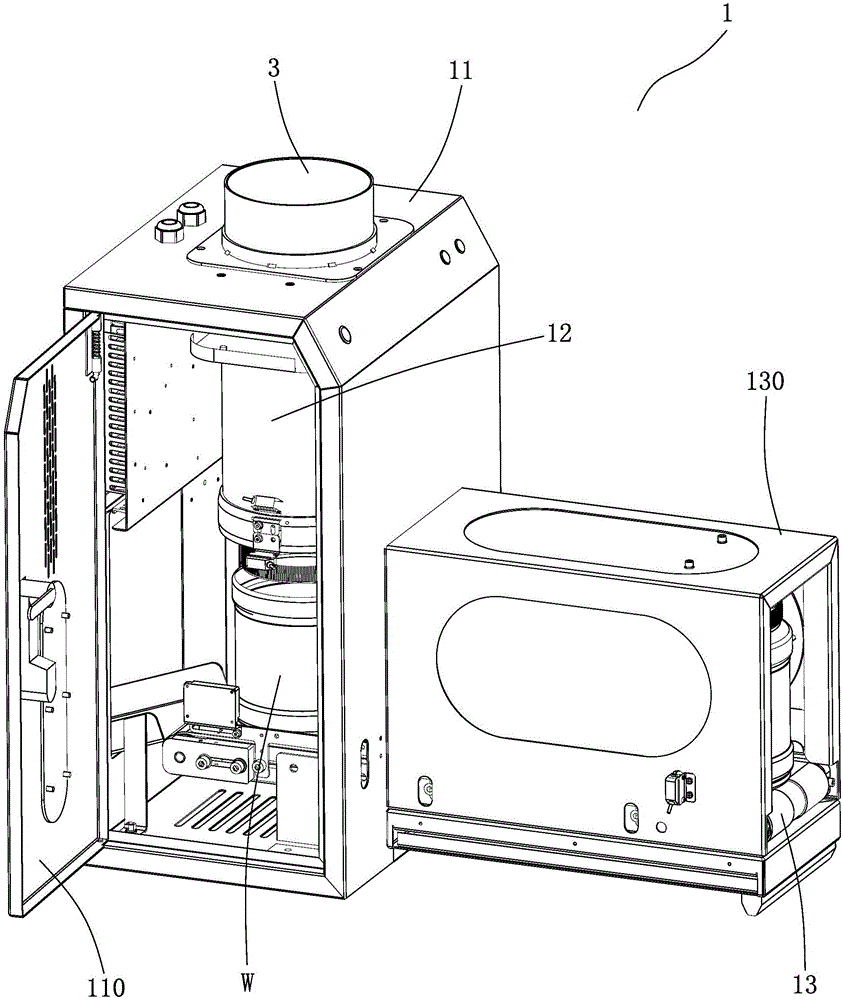

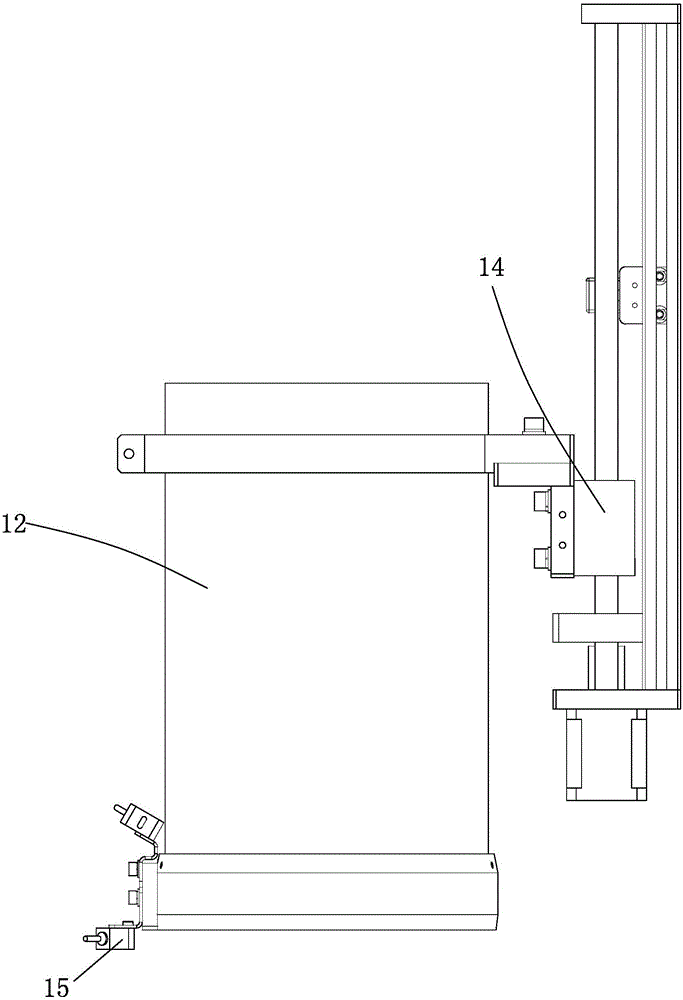

[0027] Example: see Figure 1 to Figure 10 , a pneumatic logistics workstation, including a sending workstation 1 and a receiving workstation 2, the sending workstation 1 and the receiving workstation 2 are connected through a pneumatic pipeline 3, wherein the sending workstation 1 includes a sample sending shell 11, and the pneumatic pipeline 3 extends into the sending sample shell A pipeline interface is formed in the body, and the pipeline interface is connected to the sleeve group 12. The sleeve group 12 can slide along the axial direction of the pipeline to form a telescopic lifting part. The sample bottle W is transferred to the sample sending station, and the sleeve group 12 slides down to cover the sample bottle at the sample sending station to realize the air flow sample sending operation. The sleeve group 12 is connected to the lifting slide 14, and the lifting slide 14 is installed on the sample casing 11. The sleeve set 12 is sealed and combined with the pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com