Power unit for tracklayer which bridges nonstandard gauge railway

A non-standard gauge and power unit technology, applied in the direction of the transmission device driven by the motor, can solve the problems that cannot meet the needs of the bridge and track laying machine, and achieve the effect of compact structure, stable operation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

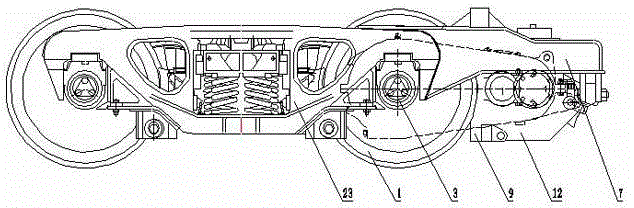

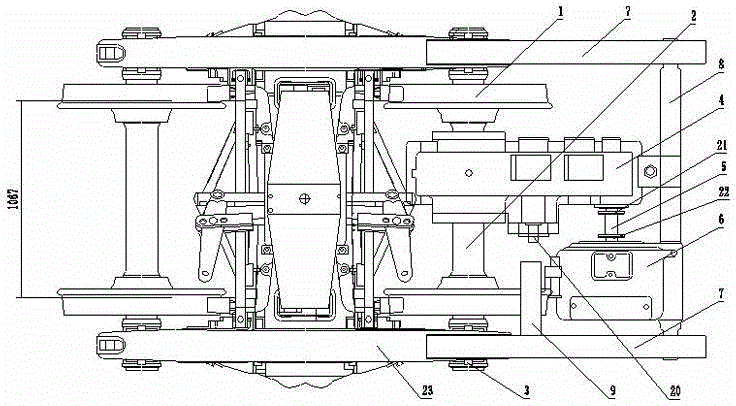

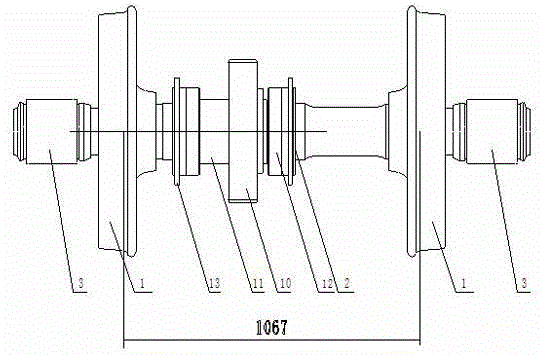

[0013] Such as figure 1 , 2 , 3, the present invention includes a power unit and a power wheel pair, and the power unit is made up of a motor suspension beam 9, a cantilever beam 7, a beam 8 welded on the vehicle bogie 23, a reduction box 4 and a traction motor 6; the traction motor 6 Suspended on the motor suspension beam 9, the cantilever beam 7 and the beam 8, the traction motor 6 is connected to the high-speed end of the reduction box 4 through the transmission shaft 5, the transmission shaft 5 is connected to the traction motor flange 22 through the input flange 21, and the reduction box 4 One end of the gear box is fixed on the beam 8, and the other end of the reduction box 4, that is, the low-speed end is press-fitted on the axle 2 of the power wheel set through the low-speed large gear 10; the power wheel set is composed of the axle box bearing 3, the integral wheel 1, the axle Gland 12, positioning sleeve 11, low-speed large gear 10, single-row tapered roller bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com