Industrial detonator packing manipulator

A technology of manipulators and detonators, which is applied in the field of industrial detonator boxing manipulators, can solve problems such as backward technical equipment, low production efficiency, and potential safety hazards, and achieve the effects of improving production safety, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

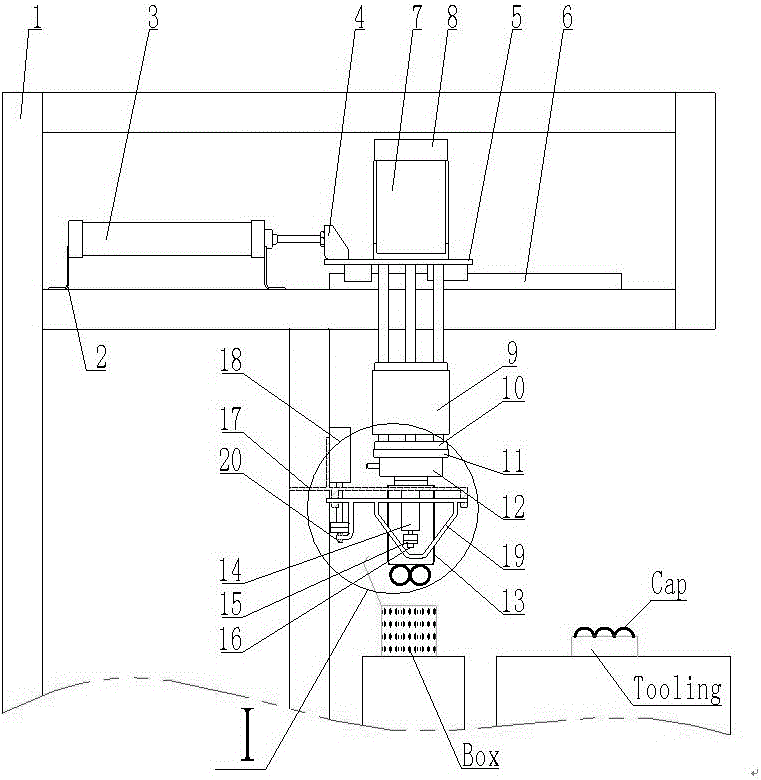

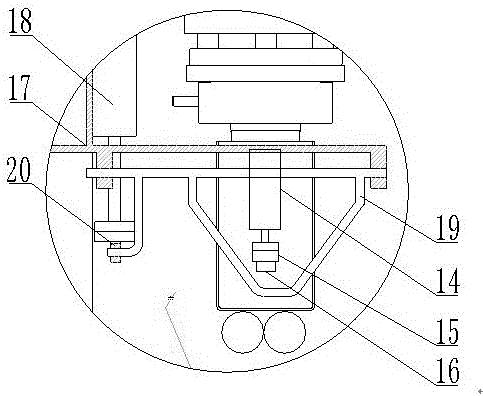

[0015] figure 1 It is the front view of the overall structure of the present invention, figure 2 It is the left view of the overall structure of the present invention

[0016] exist figure 1 - figure 2 Among them, the industrial detonator boxing manipulator of the present invention includes a frame 1, a horizontal cylinder support 2, a horizontal cylinder 3, a push plate 4, a lateral moving plate 5, a slide rail 6, a lifting cylinder A bracket 7, a lifting cylinder A8, and a lifting cylinder B bracket 9, lift cylinder B10, swing cylinder mounting plate 11, swing cylinder 12, magnet box 13, magnet lift cylinder 14, magnet mounting plate 15, magnet 16, shift fork bracket 17, leaf tongue cylinder 18, shift fork 19, The shift fork opening and closing plate 20, its connection relationship is that the horizontal cylinder support 2, the slide rail 6, and the shift fork support 17 are fixed on the frame 1, the horizontal cylinder 3 is installed on the horizontal cylinder support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com