Cloud point feeding device

A feeding device and fog point technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unqualified products, feeding, and small fog points, and achieve smooth feeding, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

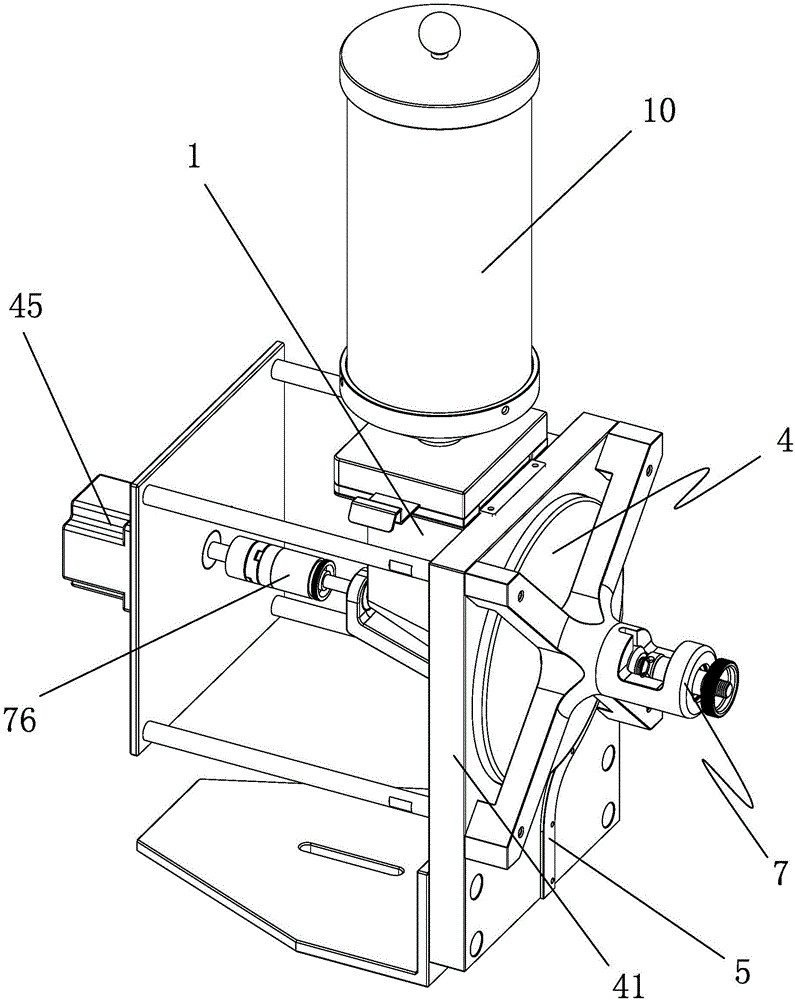

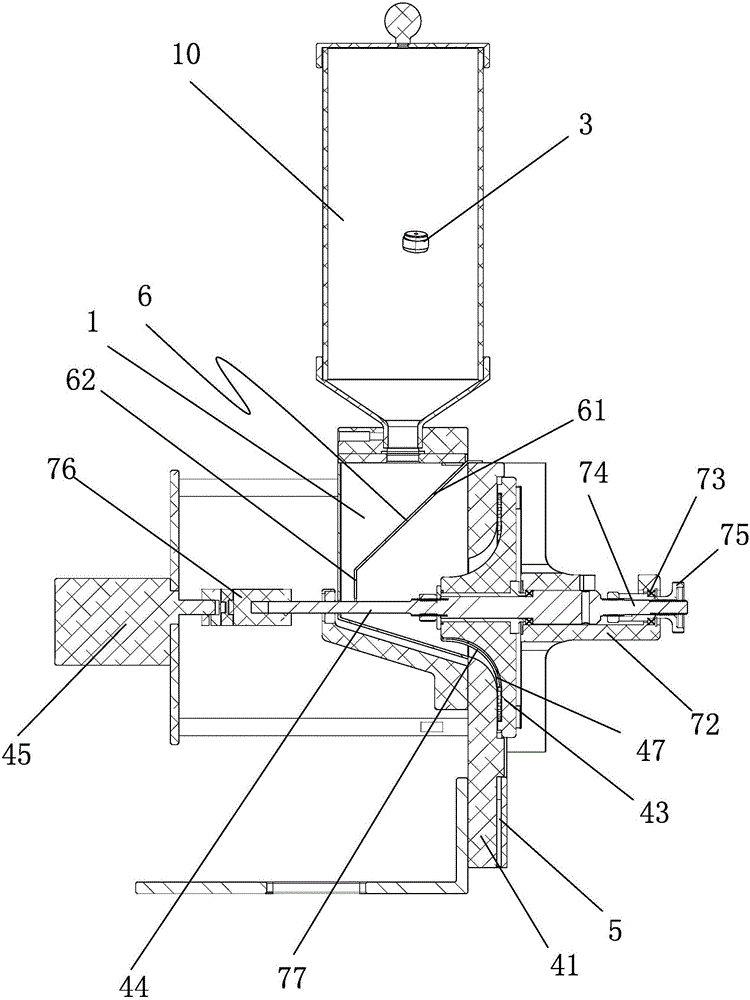

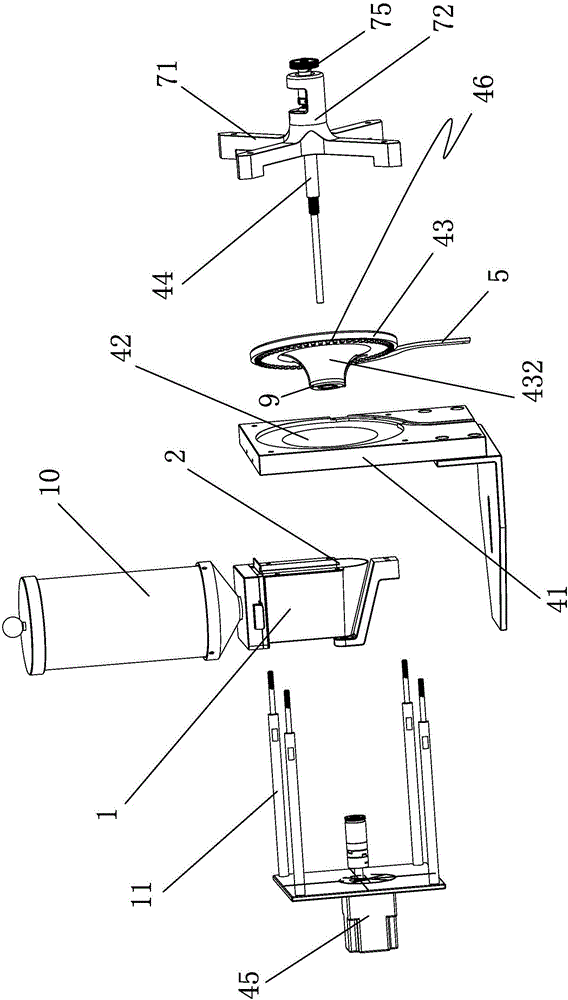

[0025] Such as Figures 1 to 4 The shown fog point feeding device includes a feeding hopper 1, and a connecting slot 2 communicating with the inner cavity of the feeding hopper 1 is provided on one side of the feeding hopper 1, and a connecting slot 2 is provided in the connecting slot 2. There is a material distribution and discharge turntable assembly 4 that enables the fog point 3 to enter and output in a predetermined direction, and a discharge rail 5 that communicates with the distribution and discharge turntable assembly 4 is connected to the supply hopper 1 .

[0026] In the present invention, the distributing and discharging turntable assembly 4 includes a fixed plate 41, on which a mounting slot 42 is arranged, and a rotating disc 43 is arranged in the installing slot 42, and the rotating disc 43 Sleeved on the rotating shaft 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com