Drilling machine with damping and for pushing inner shaft of motor to be fed in pneumatic mode

A technology that promotes motors and drilling machines. It is used in boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines. It can solve the problems affecting the efficiency of other stations, power loss and noise. It can solve the problems of combined use of the platform, etc., to achieve the effect of simple structure, low manufacturing cost and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

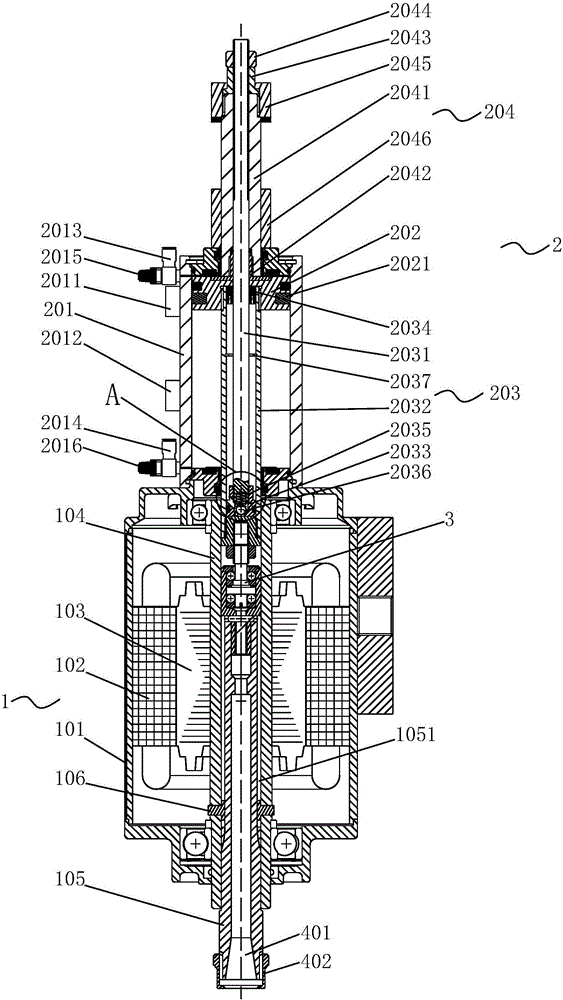

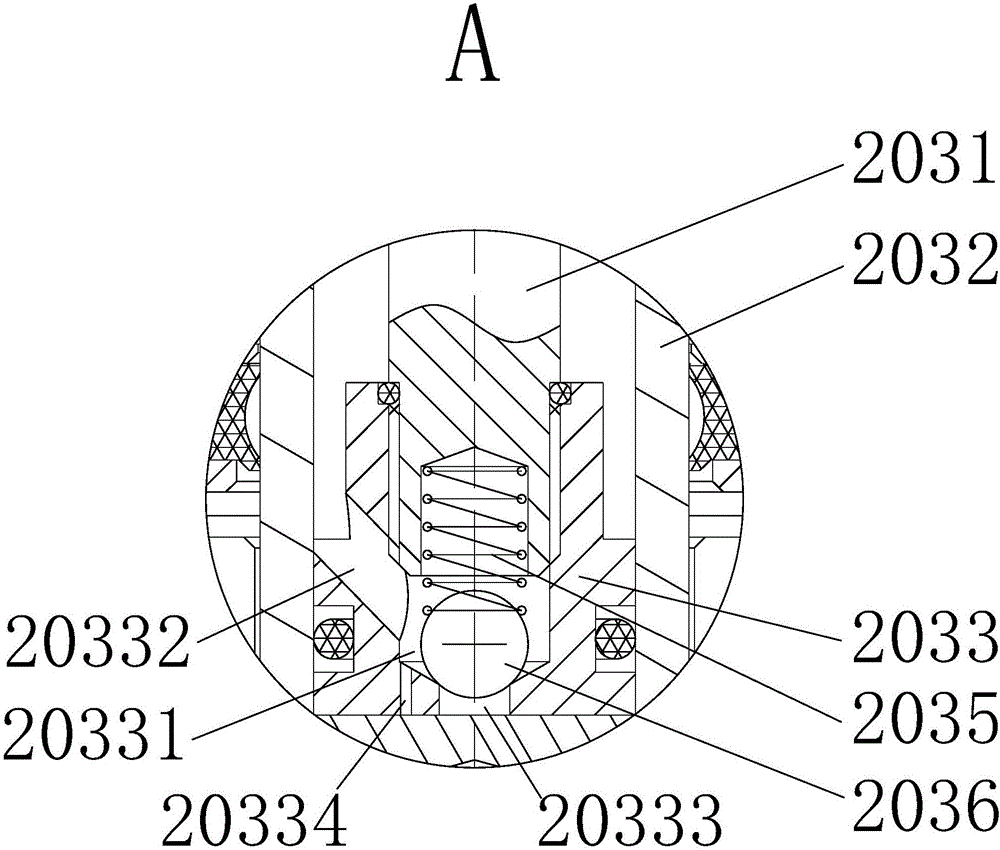

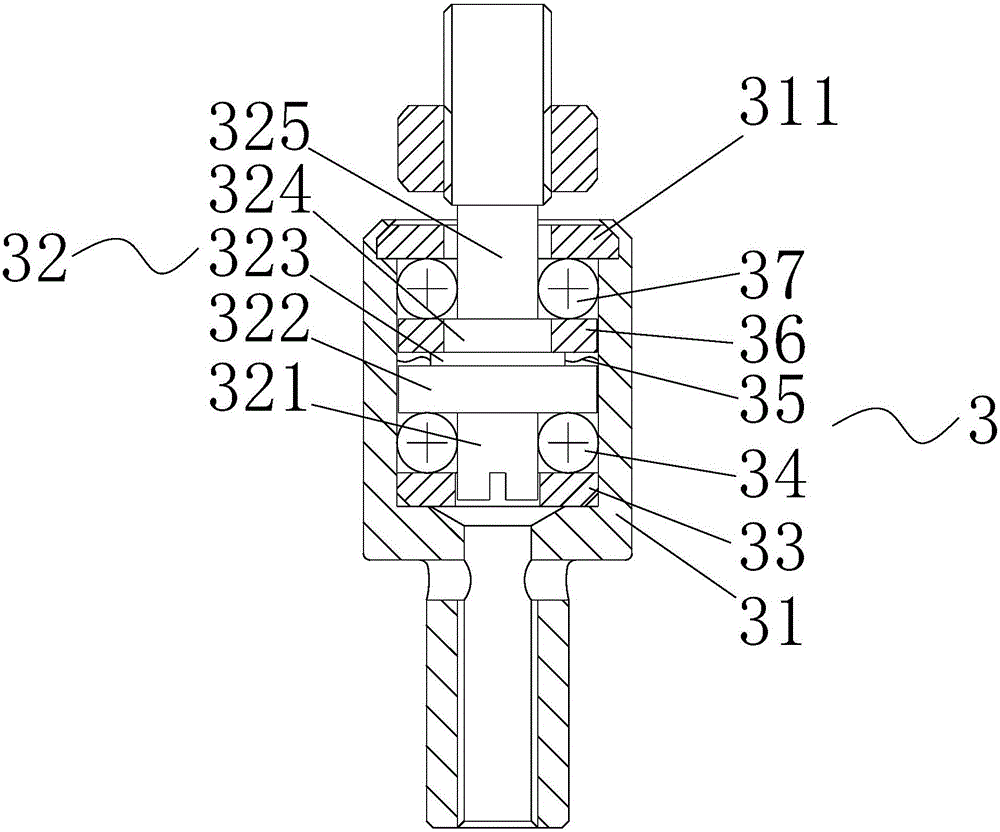

[0029] Such as Figure 1-3 As shown, the present invention provides a drilling machine with a damped pneumatic push motor inner shaft feed, which is characterized in that it includes a motor assembly 1, and the motor assembly 1 includes a The housing 101, the stator 102 fixed in the housing 101, the rotor core 103 movably arranged in the middle of the stator 102, and the motor main shaft arranged in the middle of the rotor core 103; 103 The sleeve body 104 in the central hole and the inner shaft 105 coaxially movably sleeved in the shaft sleeve body 104 body, the two ends of the shaft sleeve body 104 are rotatably connected to the housing 101, and the inner shaft 105 cannot be opposite to each other. The sleeve body 104 rotates but can move axially relative to the sleeve body 104, and the front end of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com