Preload device of a force measurement device

A technology of force measuring device and force sensor, which is applied in the direction of measuring device, force sensor in the hole of the force-bearing structure, and the measurement of the force of the property of the piezoelectric device, which can solve the problems of cumbersome fixing and achieve the prevention of interference. clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

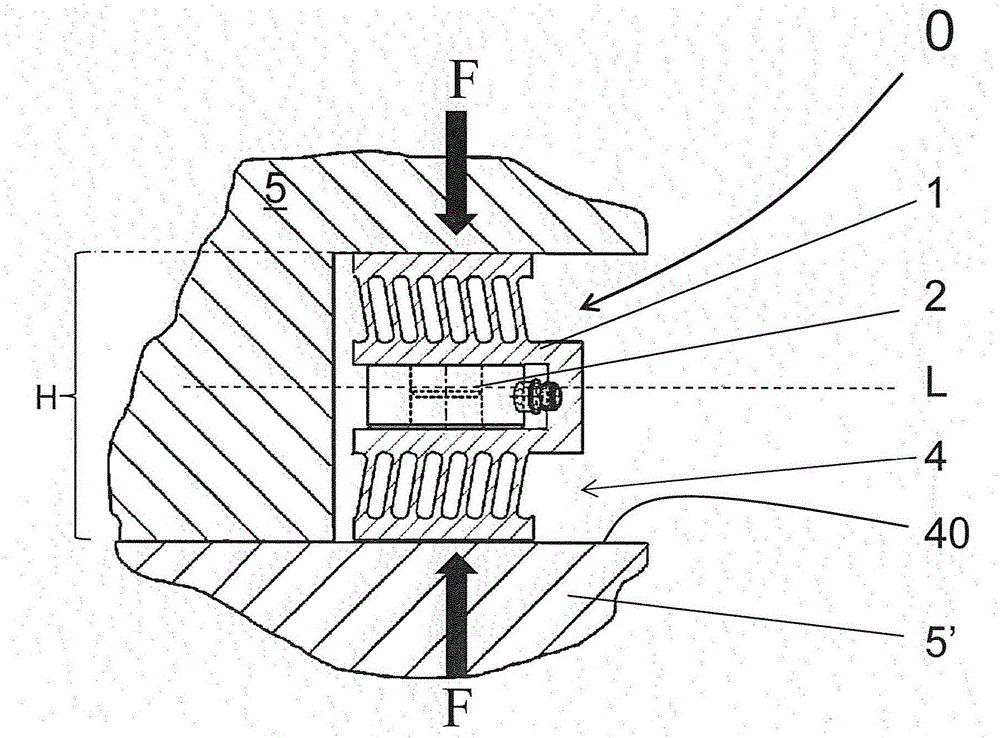

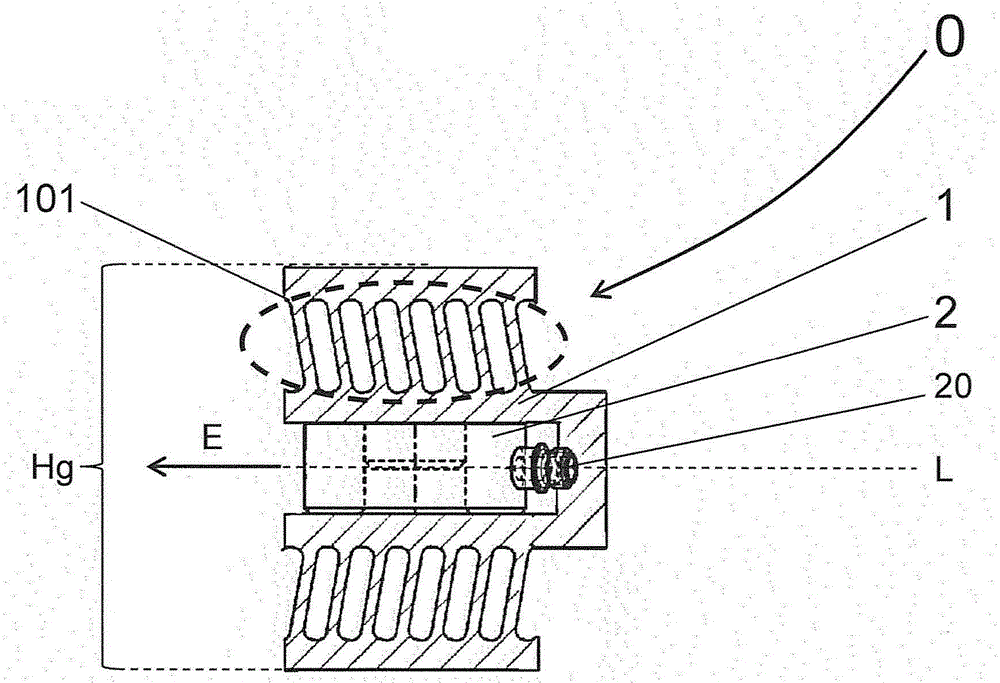

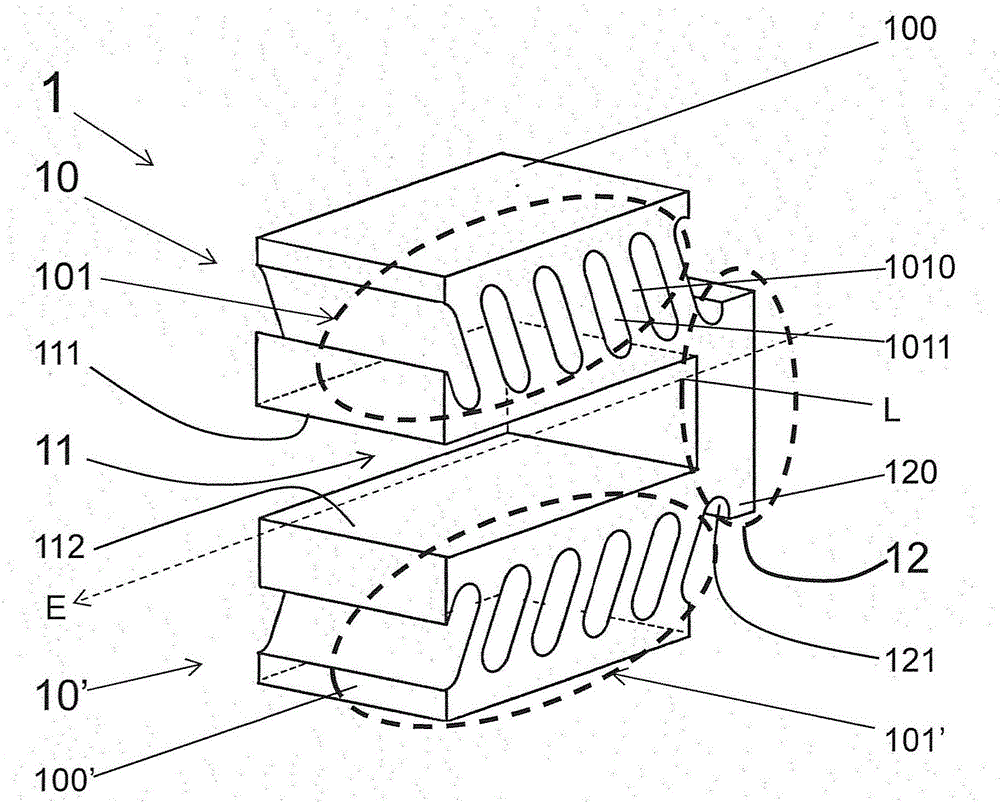

[0017] exist figure 1 A force measuring device 0 is shown in , which comprises a pretensioning device 1 and a force sensor 2 . In this case, the pretensioning device 1 is produced in one piece and inserted into the recess 4 between the two machine components 5 , 5 ′, where it is releasably clamped. The cutout 4 is formed by a planar cutout wall 40 , where the distance of the pretensioning device 1 in the direction of force transmission, characterized by a force F acting perpendicular to the longitudinal direction L, corresponds to its installation in elastic tension. State height H. The pretensioning of the pretensioning device 1 is structurally limited, since the pretensioning device 1 is elastically bendable within a defined range and can thus be introduced into the cutout 4 and can be positioned there relative to the cutout wall. 40 is held clampingly. The force F acting on the machine component 5 , 5 ′ transversely to the longitudinal axis L and thus in the clamping dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com