Preloading device for force measuring device

A force measuring device and force sensor technology, applied in the direction of measuring device, force sensor in the hole of the force-bearing structure, and the measurement of the property force of the piezoelectric device, can solve the problems of cumbersome fixing, etc., to prevent interference clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

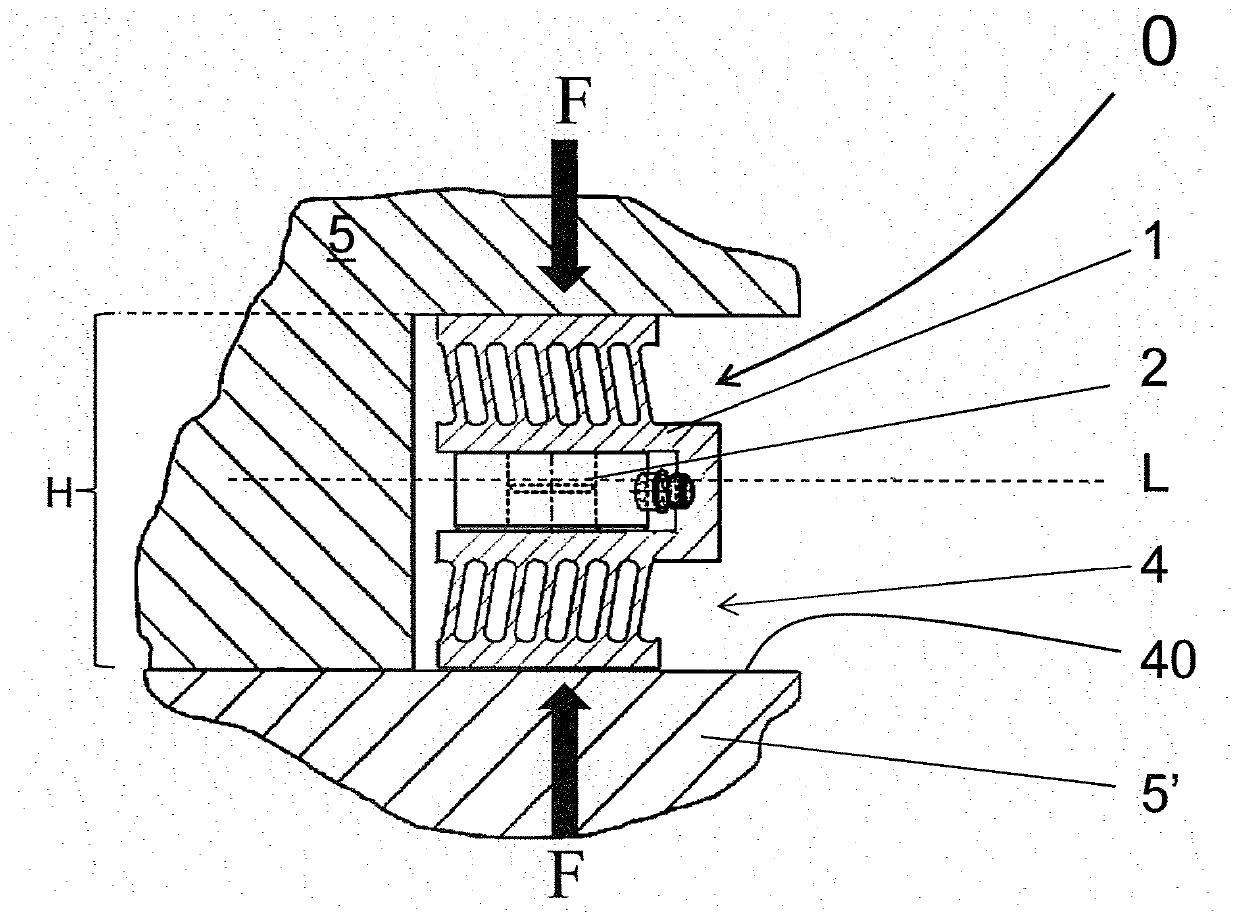

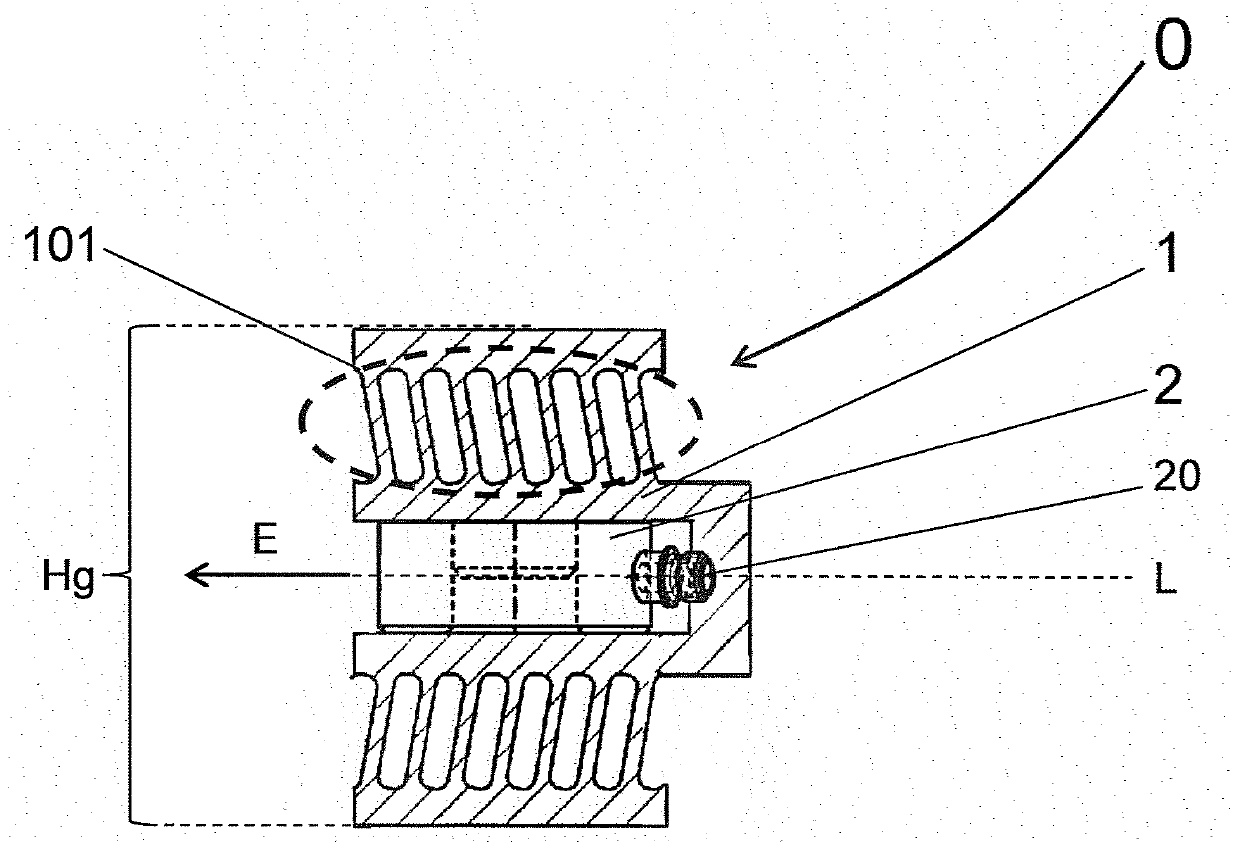

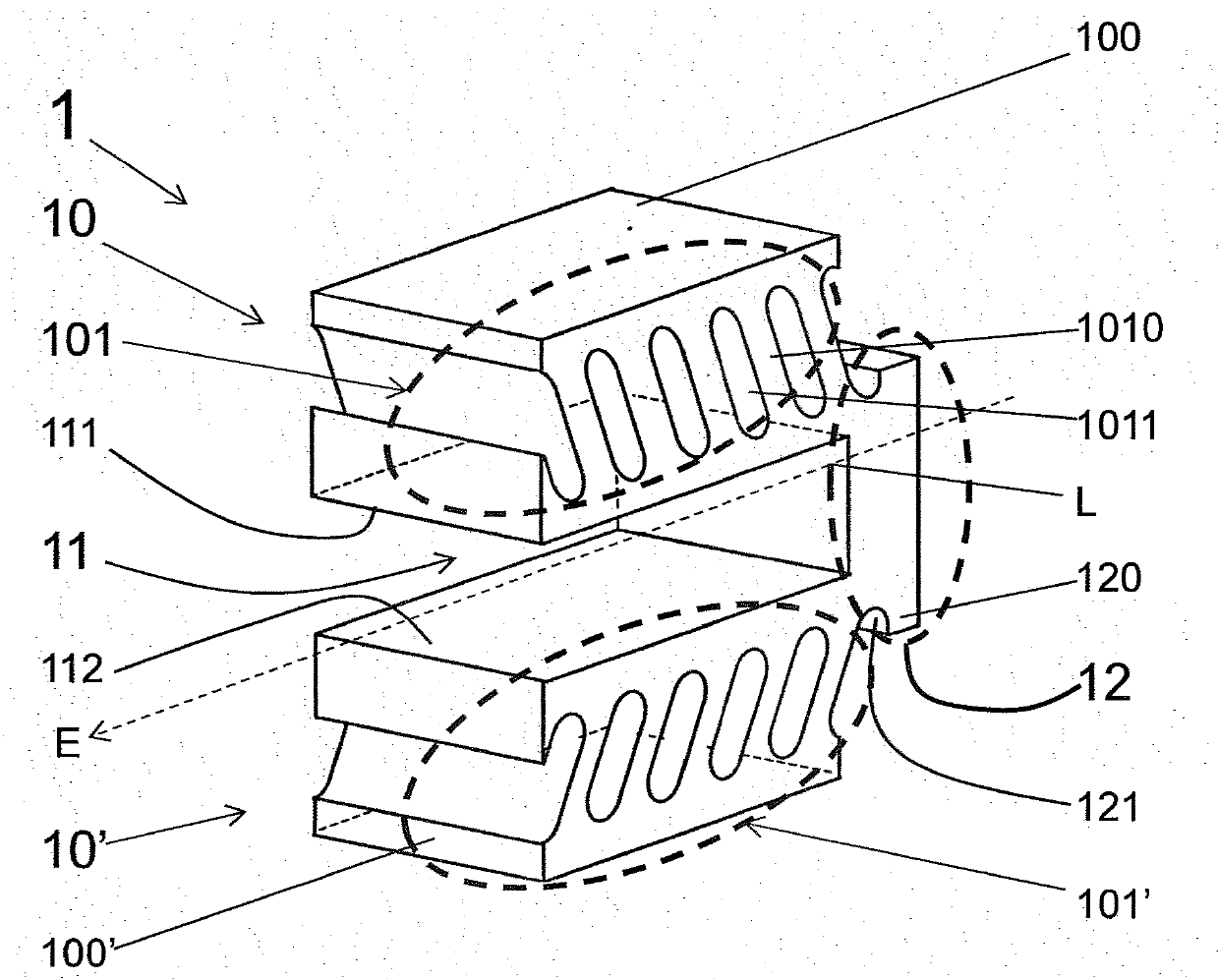

[0017] exist figure 1 A force measuring device 0 is shown in , which comprises a pretensioning device 1 and a force sensor 2 . In this case, the pretensioning device 1 is produced in one piece and inserted into the recess 4 between the two machine components 5 , 5 ′, where it is releasably clamped. The cutout 4 is formed by a planar cutout wall 40 , where the distance of the pretensioning device 1 in the direction of force transmission, characterized by a force F acting perpendicular to the longitudinal direction L, corresponds to its installation in elastic tension. State height H. The pretensioning of the pretensioning device 1 is structurally limited, since the pretensioning device 1 is elastically bendable within a defined range and can thus be introduced into the cutout 4 and can be positioned there relative to the cutout wall. 40 is held clampingly. The force F acting on the machine component 5 , 5 ′ transversely to the longitudinal axis L and thus in the clamping dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com